Biological filtration and deposition-prevention method for ornamental water

An anti-sedimentation and aquatic biology technology, applied in biological treatment devices, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of filter material clogging, affecting the permeability of filter materials, etc., and achieve the convenience of installation and removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

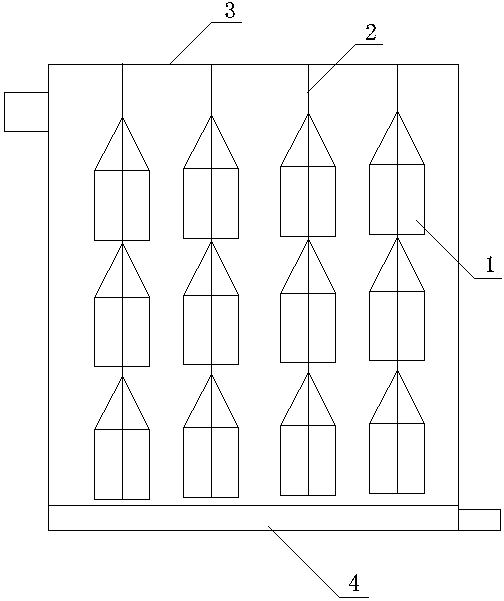

[0014] Such as figure 1 As shown, a method for filtering and preventing deposition of ornamental aquatic organisms, the porous filter material is processed into a polyhedron 1 with a pointed or arc-shaped upper surface, holes are opened along the central axis of the polyhedron 1, and linear objects 2 are connected in series to form a series. Groups and multiple groups are matched to form a vertical curtain, which is vertically arranged in the ornamental water filter box 3 in a free-falling shape. Microorganisms and biofilms in the water are all attached to and live on the porous materials in strings. A sewage discharge tank 4 is set at the bottom of the filter box. Disturbance of water flow, microbial decomposition products and biofilm shedding materials can sink into the sewage tank in time to prevent the deposition and blockage of microbial decomposition products and biofilm shedding materials on the filter material.

[0015] The comparison between the quality of the existin...

Embodiment 2

[0017] As a further design of Example 1, the pointed shape or circular arc shape is a spherical surface, an elliptical surface, a conical surface or a multi-pointed conical surface.

[0018] The height of the strings connected in series is the same as the height in the filter box.

[0019] As for the design of the structure, the design of the height is feasible as long as it meets the requirements of Embodiment 1. Different structures and heights will have different effects.

[0020] But the difference is only the preferred and non-preferred result, not the difference in method, therefore, its selection still belongs to the protection scope of the present invention.

Embodiment 3

[0022] As a further design of implementation example 1, the sewage discharge tank 4 is a sewage discharge groove arranged at the bottom of the filter box, the sewage discharge groove is connected to the sewage discharge pipe, a sewage discharge valve is installed on the sewage discharge pipe, and the sewage discharge valve is opened regularly to clean up in time to prevent the filter material from Deposition and clogging of microbial decomposition products and biofilm shedding.

[0023] It can be seen from the above embodiments that the present invention combines disordered and disordered filter materials in multiple groups in series to form a curtain type, and designs a special structure for the porous filter material, and utilizes the disturbing effect of circulating water flow and the special structure to The microbial decomposition and biofilm shedding are discharged in time, without depositing and clogging on the material, so that the filter material always maintains excel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com