Novel condenser guide pipe assembly assembling mechanism

A condenser and conduit technology, applied in the field of new condenser conduit assembly assembly mechanism, can solve the problems of drying, single filtering function, complex structure design, high manufacturing cost, eliminate defects and customer complaints, and reduce storage space. The effect of saving area and changing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

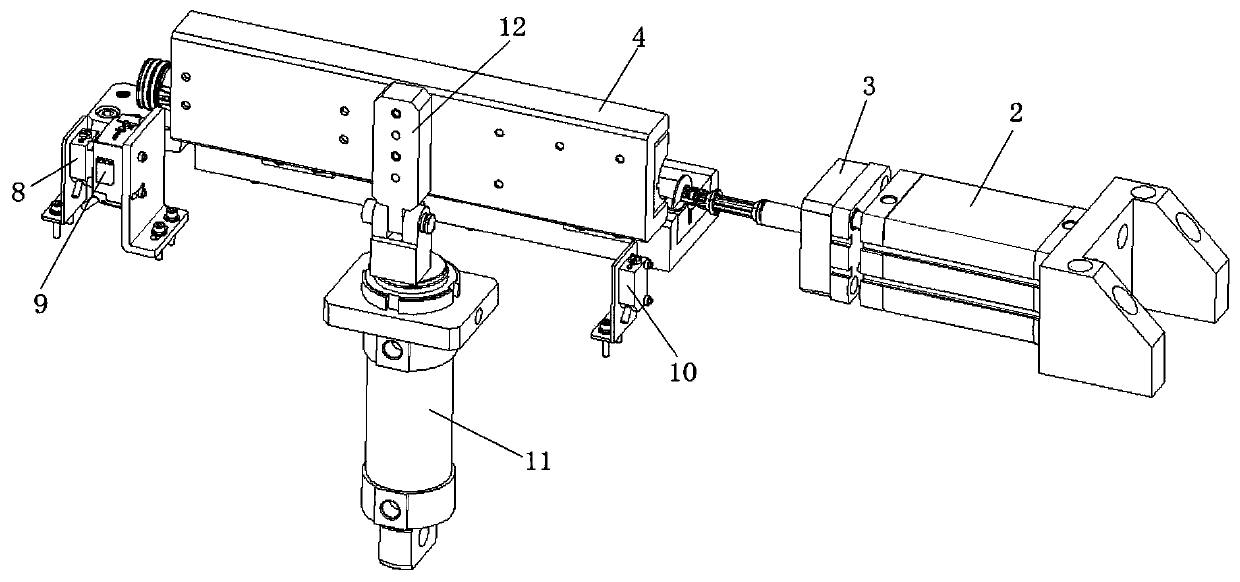

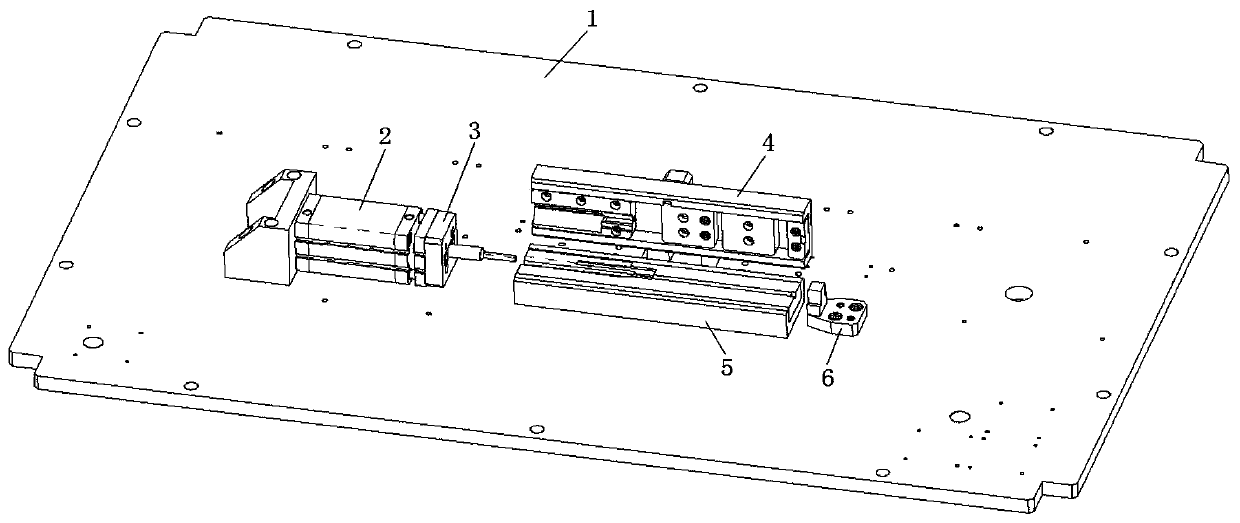

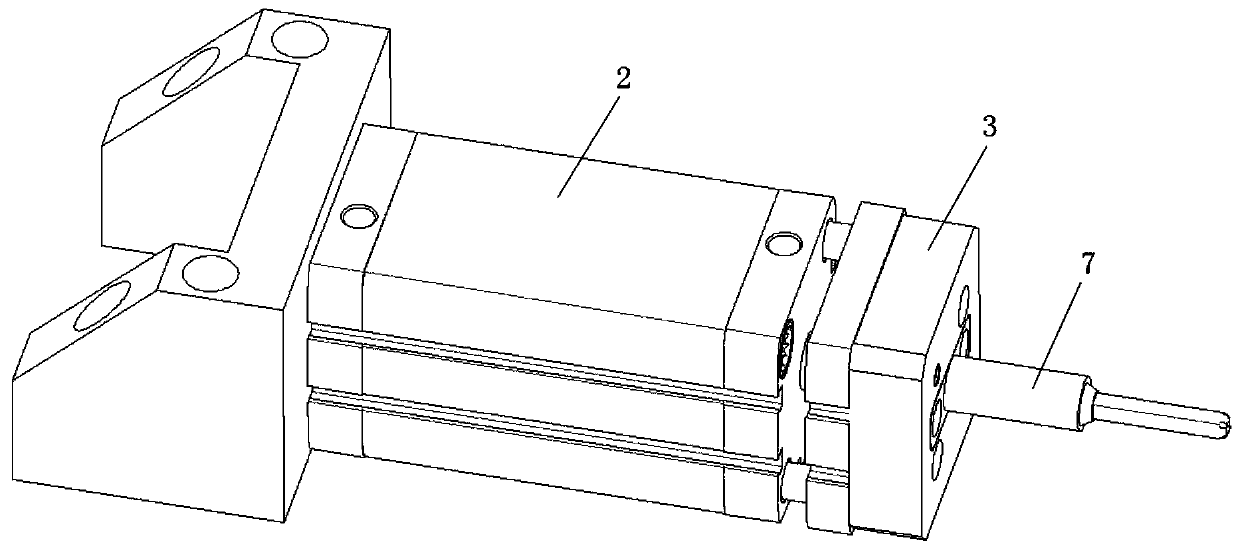

[0022] specific embodiment Figure 1 to Figure 11 As shown, the present invention includes an assembly table 1, an X-axis cylinder 2, a thimble base 3, an upper platen 4, a base groove 5, a liquid separator fixing block 6, a filter thimble 7, a clogging recognition sensor 8, and a color recognition of a liquid sealing ring Sensor 9, filter recognition sensor 10, Z-axis cylinder 11, support plate 12, plug 13, liquid separation seal ring 14, conduit 15, filter support 16, filter 17, the assembly table 1 has multiple bolt installation holes , X-axis cylinder 2, base groove 5, liquid distributor fixing block 6, clogging recognition sensor 8, liquid separation sealing ring color recognition sensor 9, filter recognition sensor 10, Z-axis cylinder 11 are all fixed on the assembly table 1 by bolts The thimble base 3 is installed and connected with the right end face of the X-axis cylinder 2, the filter thimble 7 is installed on the thimble base 3; the X-axis cylinder 2 is located on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com