A kind of cu-mo-s composite material and its preparation method and application

A composite material, cu-mo-s technology, applied in the field of electrochemistry, can solve the problems of weak metal and hydrogen bonding and inability to stabilize the intermediate state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

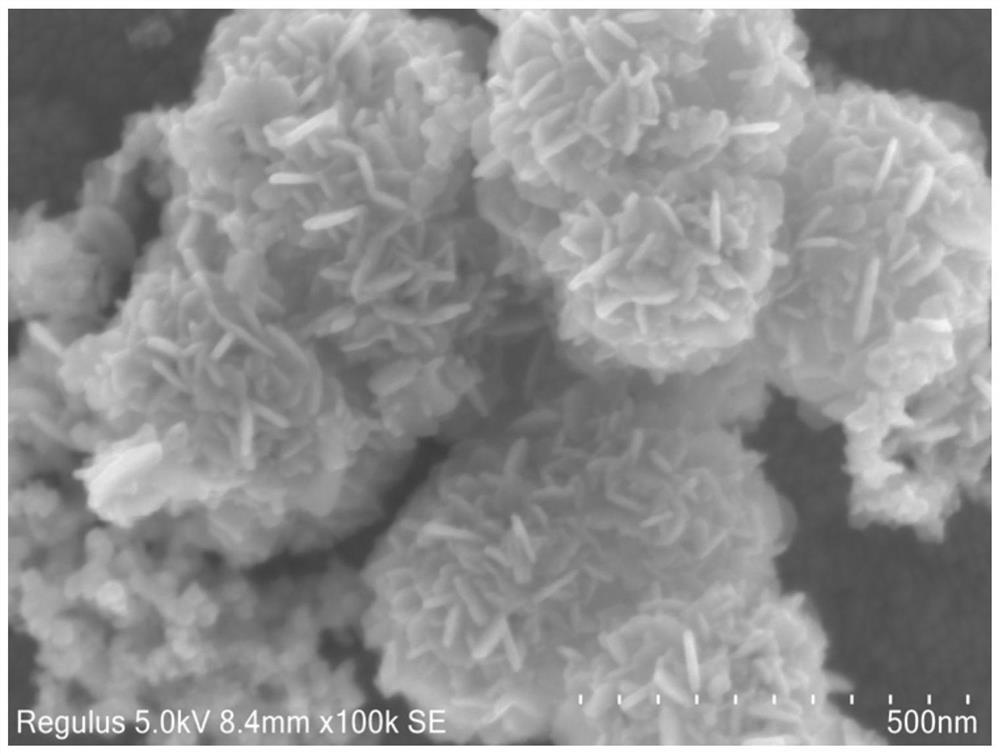

[0026] The present invention provides a kind of preparation method of Cu-Mo-S composite material, comprises the following steps: (1) in the mixed solution of alcohol and water, add divalent copper salt, molybdate and sulfur source and mix until dissolving; (2 ) and then add a reducing agent, transfer to a high-temperature reactor for heating reaction; (3) centrifuge the system after the heating reaction to remove liquid, and dry the obtained product.

[0027] In the above technical solution, the Cu-Mo-S composite material has better catalytic stability and catalytic activity in the hydrogenation reaction, and at the same time, the preparation method is simple and fast, and the cost is lower, so it has wider application prospects. The reason, we speculate: the transition metal Cu has unpaired 3d electrons in the outer shell of the atom, it is easy to pair with the 1s orbital of the hydrogen atom during the electrocatalytic hydrogen evolution reaction to form a Cu-H adsorption bo...

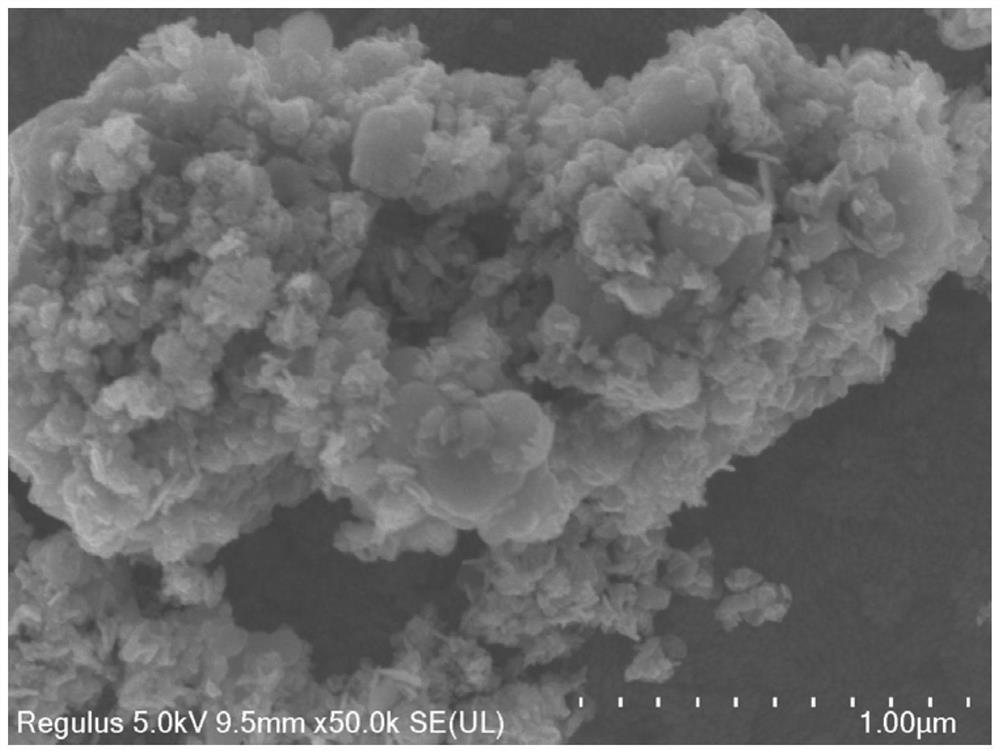

Embodiment 1

[0048] Weigh 241.6mg copper nitrate trihydrate (1mmol), 241.95mg sodium molybdate dihydrate (1mmol), 75.13mg thioacetamide (1mmol), dissolve in 40mL twice distilled water and 30mL absolute ethanol respectively at room temperature In the solution, stir at room temperature for 30 minutes until dissolved, add 5 mL of hydrazine hydrate to the mixture, transfer it to a high-pressure reactor, set the reaction temperature to 120° C., and the reaction time to 4 hours. After the temperature of the reaction kettle was lowered to room temperature, it was centrifuged and washed, and vacuum-dried at 60°C for 18 hours to obtain a Cu-Mo-S composite material, which was designated as A1.

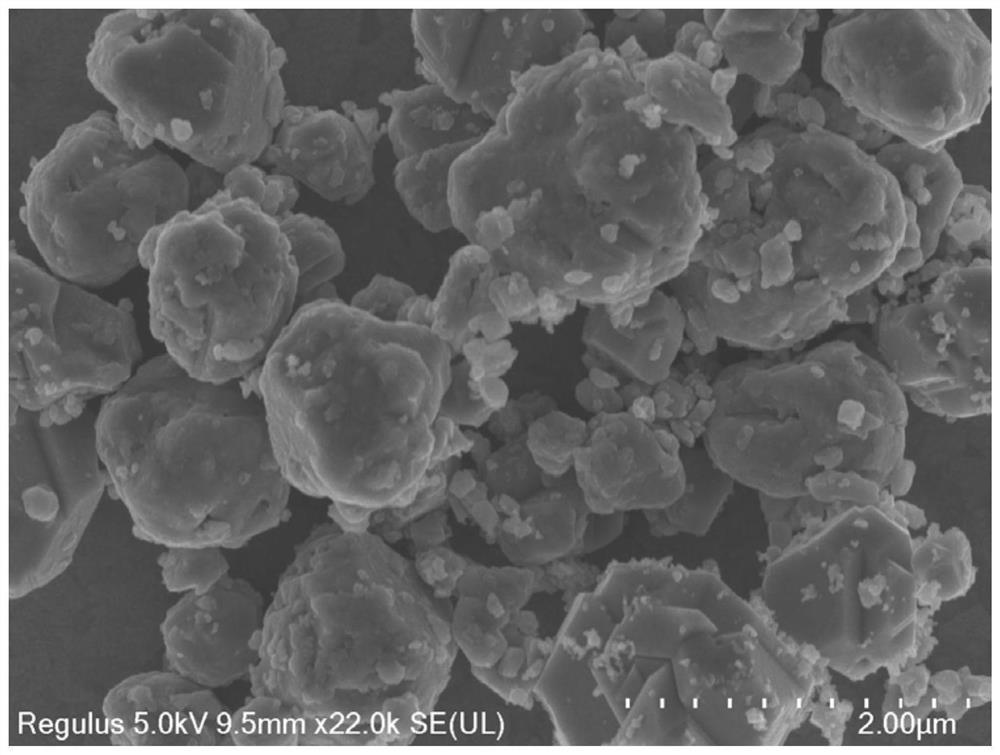

Embodiment 2

[0050] Weigh 241.6 mg of copper nitrate trihydrate (1 mmol), 140 mg of sodium molybdate dihydrate (about 0.6 mmol), and 30 mg of thioacetamide (0.4 mmol), and dissolve them in 40 mL of twice distilled water and 40 mL of absolute ethanol at room temperature. In the mixed solution, stir at room temperature for 30 min until dissolved, add 5 mL of hydrazine hydrate to the mixed solution, transfer to an autoclave, set the reaction temperature to 100° C., and the reaction time to 6 h. After the temperature of the reaction kettle was lowered to room temperature, it was centrifuged and washed, and vacuum-dried at 60°C for 18 hours to obtain a Cu-Mo-S composite material, which was designated as A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com