lamellar micro flower-like mos 2 /ni 3 the s 2 /nife-ldh/nf material and its synthesis method and application

A synthesis method and lamellar technology are applied in the synthesis and application fields of electrocatalytic materials, which can solve the problems of high-cost industrial production of noble metal-based catalysts, and achieve good bifunctional catalytic activity, good application prospects, high catalytic activity and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

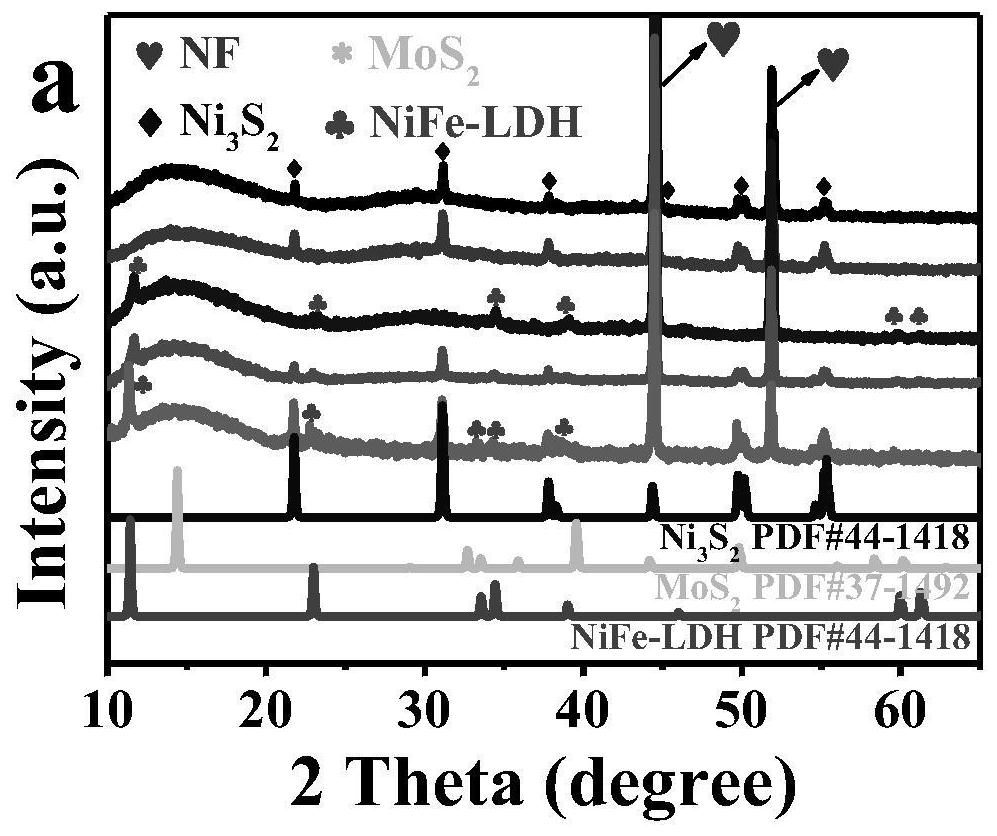

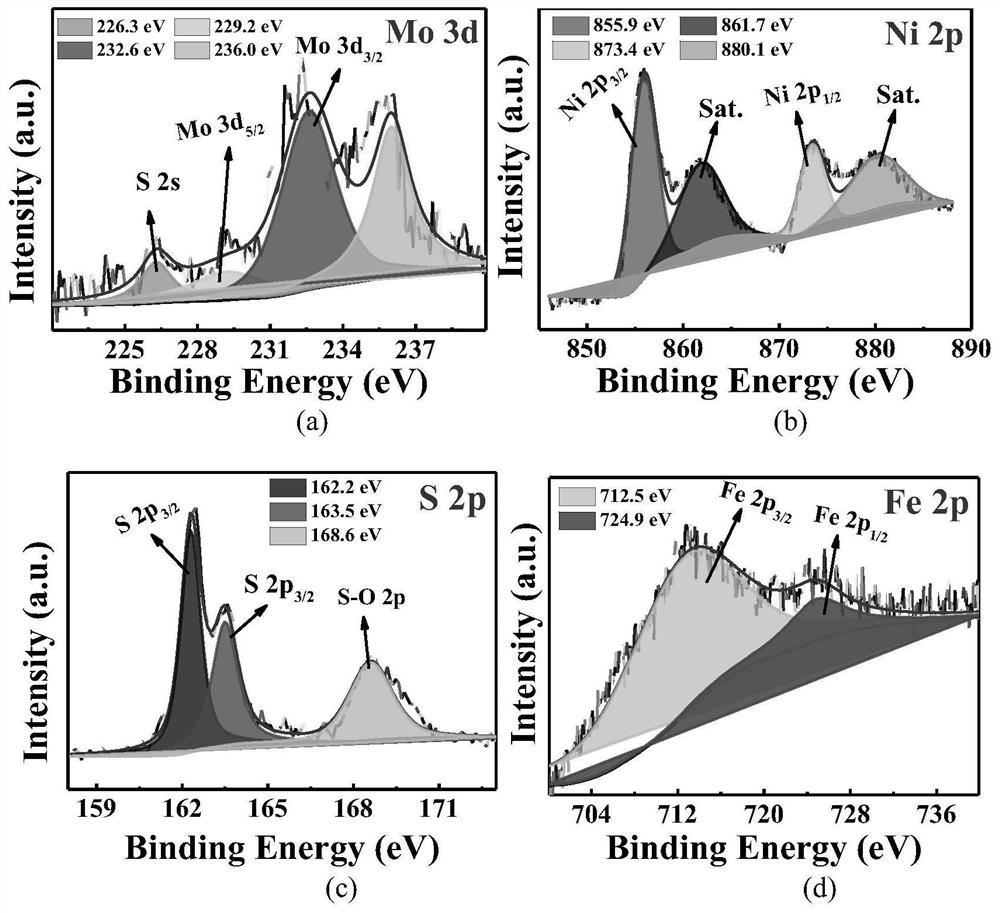

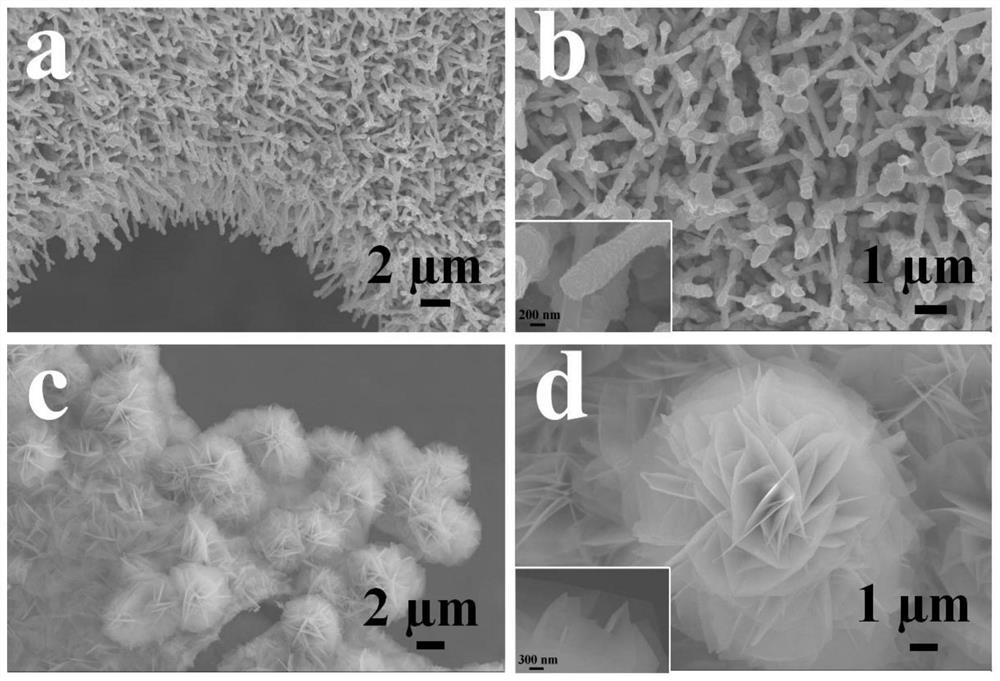

[0054] A kind of sheet-layer micro-flower-like MoS of this embodiment 2 / Ni 3 S 2 The synthetic method of / NiFe-LDH / NF material comprises the steps:

[0055] (1) Foam nickel (NF) pretreatment

[0056] Cut the nickel foam into 2*4cm, ultrasonically clean it with 3M HCl, acetone, ultrapure water and ethanol for 15 minutes, and dry it in vacuum at 60°C for later use.

[0057] (2) Nanorod array MoS 2 / Ni 3 S 2 Synthesis of / NF

[0058] 0.5 mmol sodium molybdate dihydrate (Na 2 MoO 4 2H 2 O) and 2 mmoles of thiourea (CS(NH 2 ) 2 ) into 60 milliliters of ultrapure water, magnetically stirred to form a homogeneous solution, then transferred to 100 milliliters of the reaction kettle, then adding the pretreated nickel foam in the solution in step (1), the reaction kettle After sealing, put it into a blast drying oven, set the reaction temperature to 200°C, and react at a constant temperature for 24 hours. After the temperature dropped to room temperature, the reacted nickel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com