Magnetorheological Elastomer-Magnetorheological Fluid Composite Shock Absorber for Rotational Vibration

A magnetorheological elastomer and magnetorheological fluid technology, applied in the field of vibration damping, can solve the problems of not being able to reduce and change the energy transfer rate, not being able to consume vibration energy, etc., to achieve the effect of convenient processing and increased flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

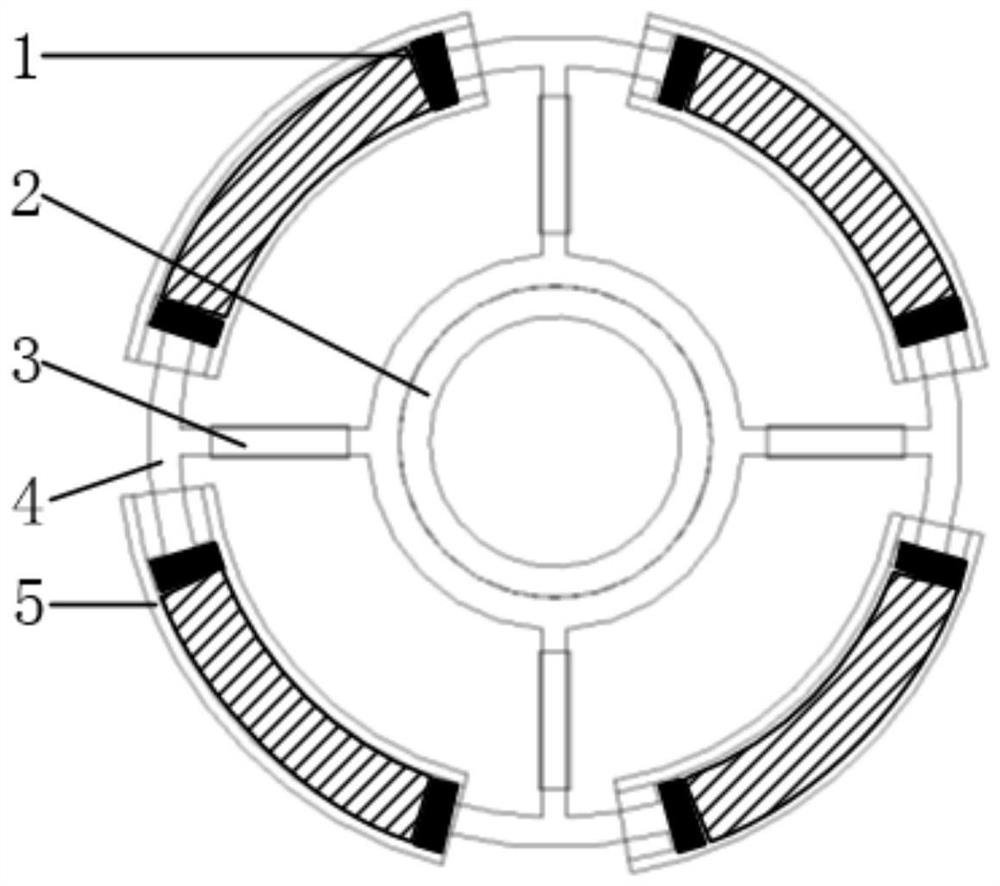

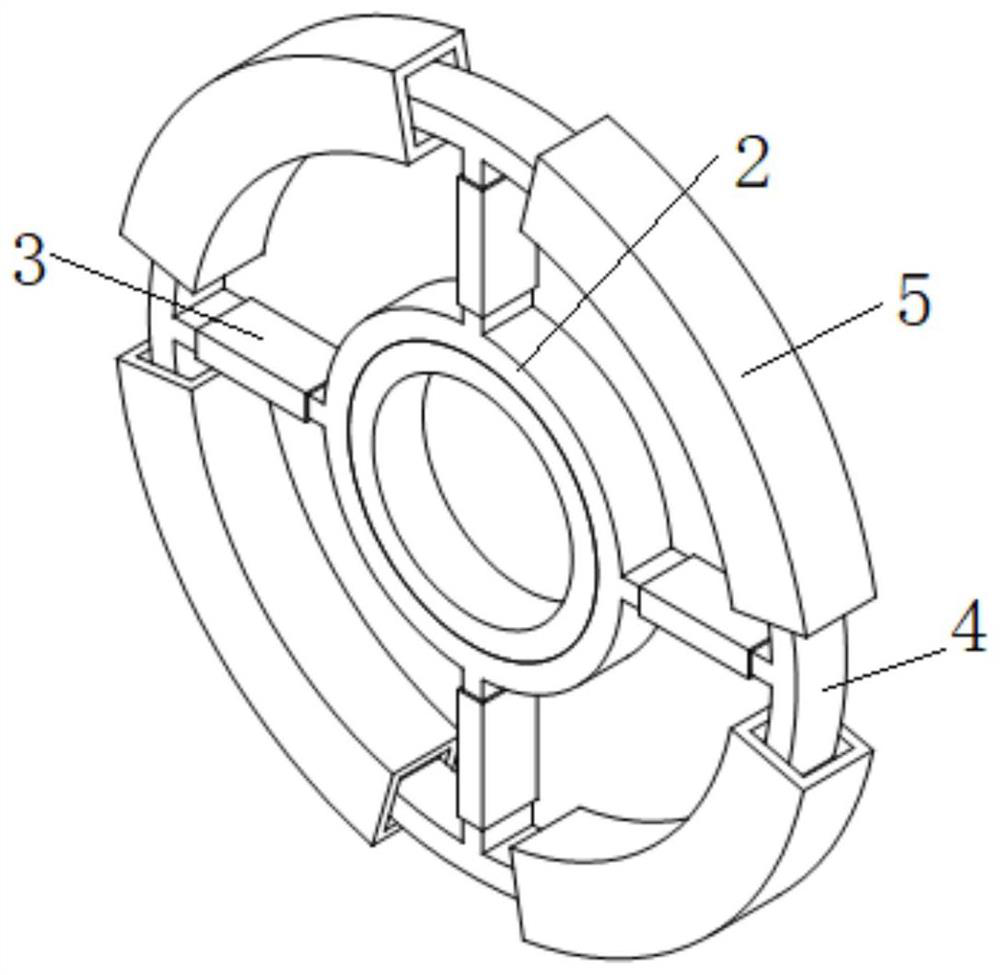

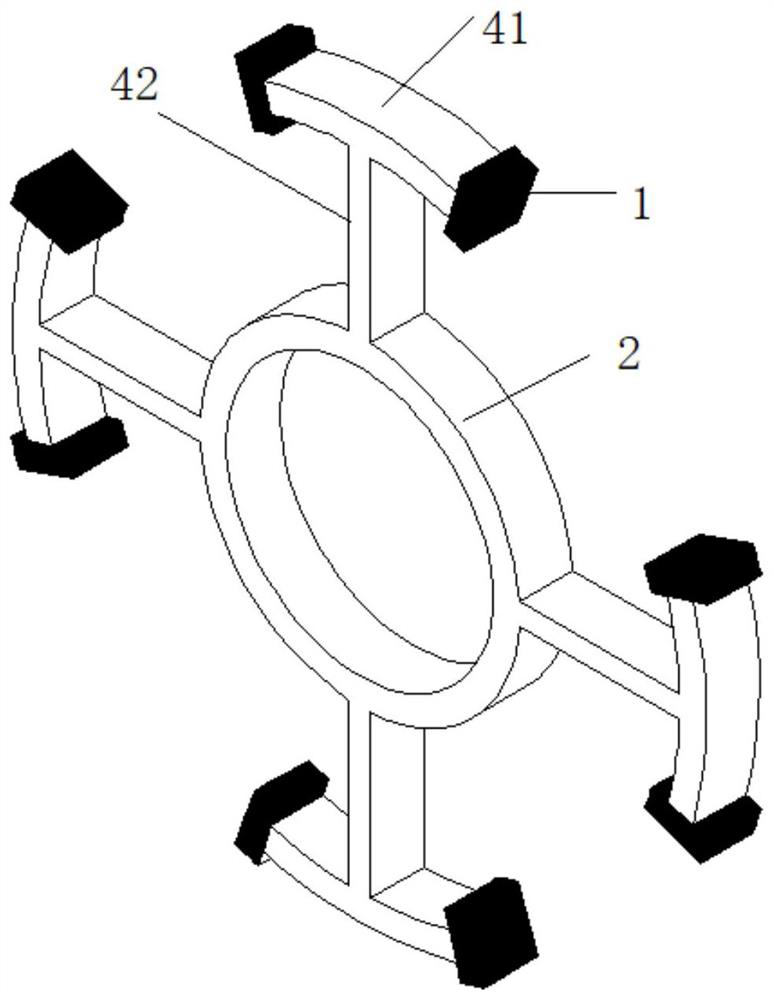

[0020] A magneto-rheological elastomer pipeline shock absorber, including an annular magnetorheological elastomer 2, a rotating bracket 4, four coils 3, four tubes 5 filled with magnetorheological fluid, and eight rubber seals 1 piece;

[0021] The annular magnetorheological elastomer 2 is located at the center of the entire vibration isolator, and its inner ring is used to install the vibration shaft. When the vibration shaft rotates and vibrates, the vibration will be transmitted to the vibration isolator through the annular magnetorheological elastomer 2 ; The inner ring of the rotating bracket 4 is fixedly connected with the outer ring of the annular magnetorheological elastomer 2 by gluing, and rotates with the rotation of the annular magnetorheological elastomer 2, and the outer ring is fixedly connected by gluing There are 8 rubber blocks; the rubber blocks are in close contact with the inner wall of the pipe 5 and can move relatively, and every two rubber blocks seal a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com