Self-adaptive assembling device for paired press fitting of bearings

An assembly device and self-adaptive technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficulty in ensuring the consistency of assembly quality, high cost, and incomplete synchronization of bearing press-fitting, etc., and achieves a stable and reliable method. The effect of stable gripping bearing and high press-fitting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

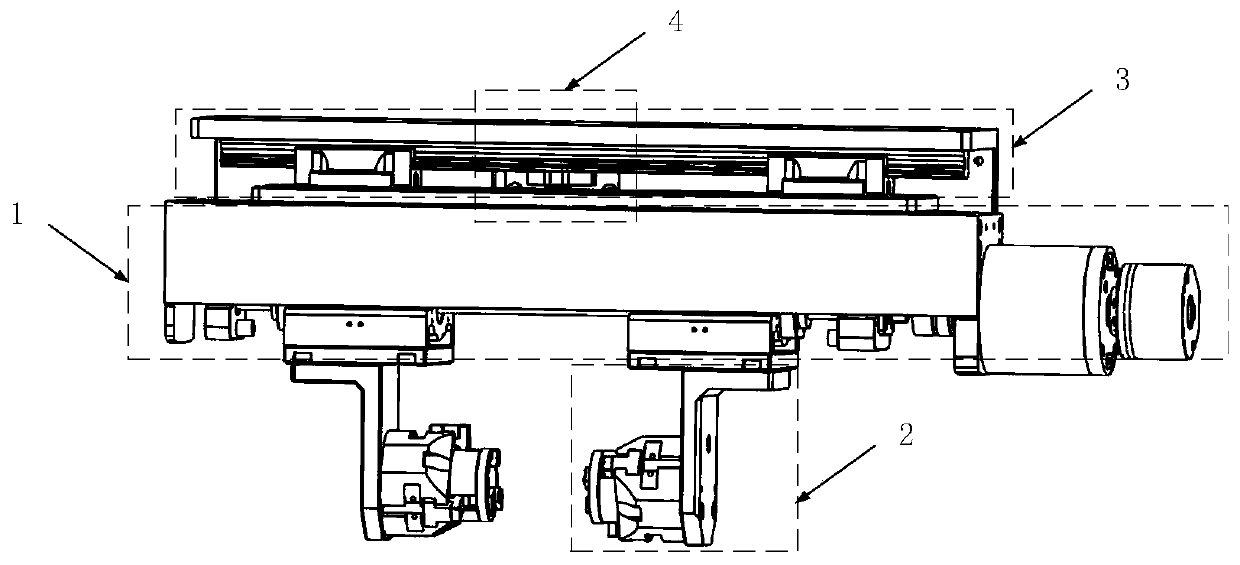

[0036] The present invention is a self-adaptive assembly device for paired press-fitting of bearings, such as figure 1 As shown, it includes a screw guide rail module 1 , a mechanical claw assembly 2 , a self-moving guide rail slider assembly 3 and a reset cylinder assembly 4 .

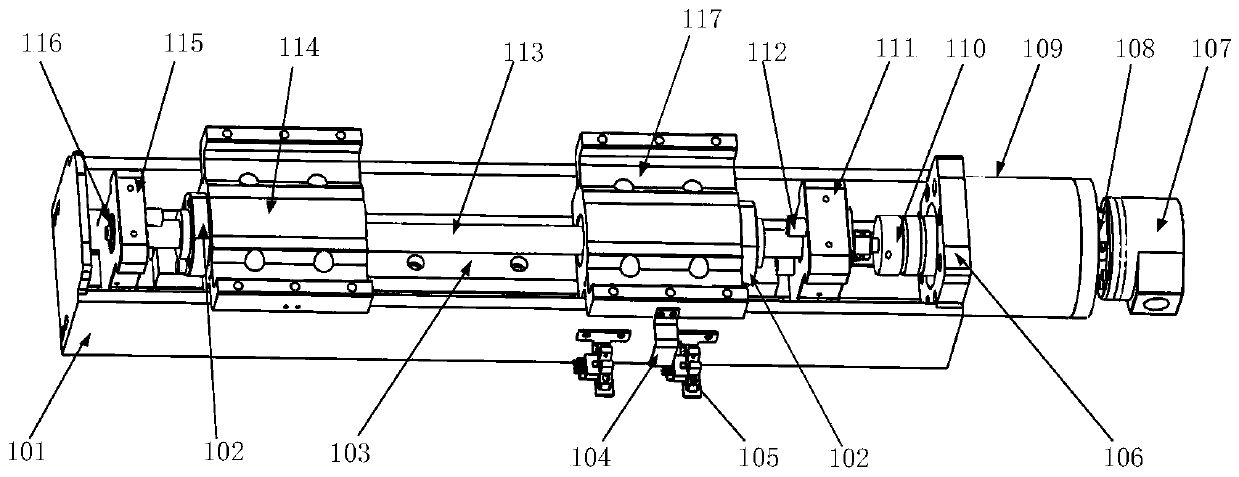

[0037] The screw guide rail module 1 includes a base 101, a screw nut 102, a linear guide rail 103, a photoelectric trigger plate 104, a photoelectric switch sensor 105, a bearing end cover 106, a right end cover 106, an absolute encoder 107, and an encoder fixing bracket 108, DC servo motor 109, shaft coupling 110, right support seat 111, anti-collision block 112, leading screw 113, left slide block 114, left support seat 115, deep groove ball bearing 116 and right slide block 117, as figure 2 shown. Wherein, the inside of the base 101 is provided with a lead screw 113 al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com