In-situ real time observation device with X-ray fluoroscopy

An observation device, X-ray technology, applied in measurement devices, electrical devices, material analysis using radiation, etc., can solve the problem of inability to heat the temperature field gradient of the sample

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and the following embodiments. It should be understood that the accompanying drawings and the following specific embodiments are only used to illustrate the present invention, rather than limit the present invention.

[0028] The invention belongs to the technical field of X-ray fluoroscopy high-temperature real-time observation, and is mainly applicable to in-situ real-time observation of melting and solidification processes of melts at high temperatures (up to 1600 degrees Celsius) by using X-rays.

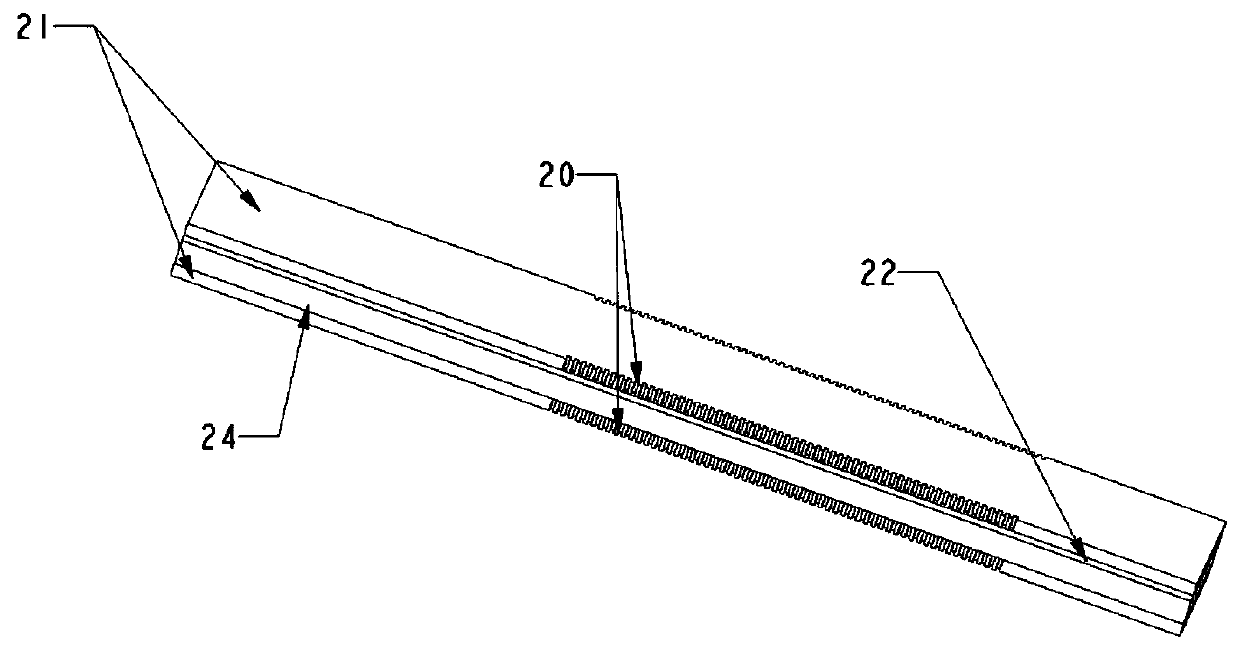

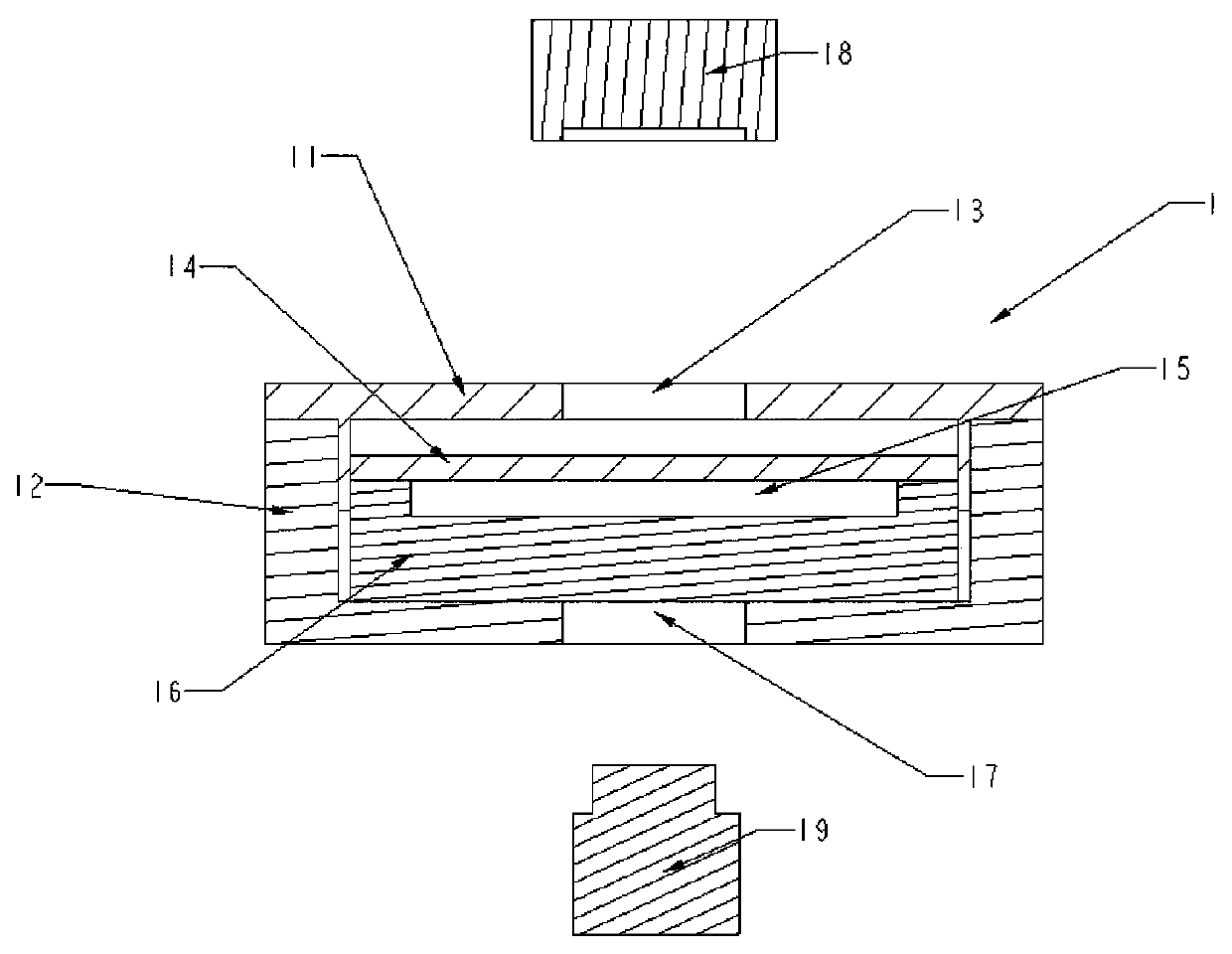

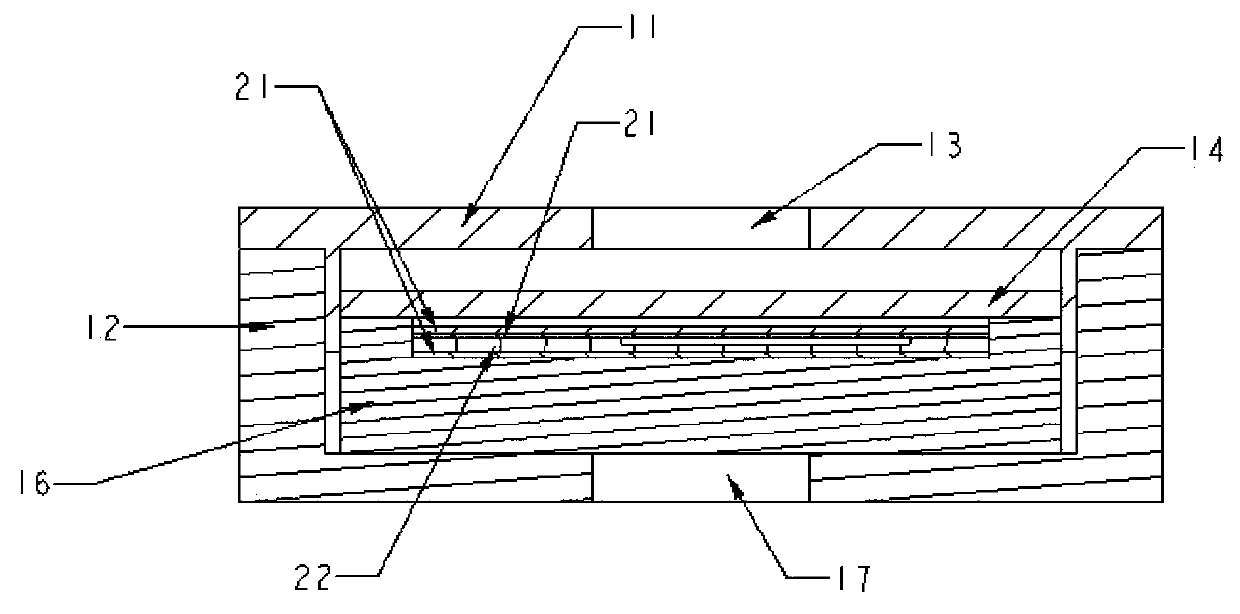

[0029] figure 1 An overall sectional view of an X-ray fluoroscopy in-situ real-time observation device according to an embodiment of the present invention is shown. The X-ray fluoroscopy high-temperature in-situ real-time observation device includes a sealed box 1 and an X-ray unit capable of emitting X-rays penetrating the sealed box 1 .

[0030] In this embodiment, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com