Experimental device of variable-structure rocket-based-combined-cycle combustion chamber

A combination of power and experimental device technology, applied in the direction of measuring devices, machine/structural component testing, engine testing, etc., can solve problems such as dynamic sealing, achieve optimized performance, simplify control and adjustment rules, and improve implementation and reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

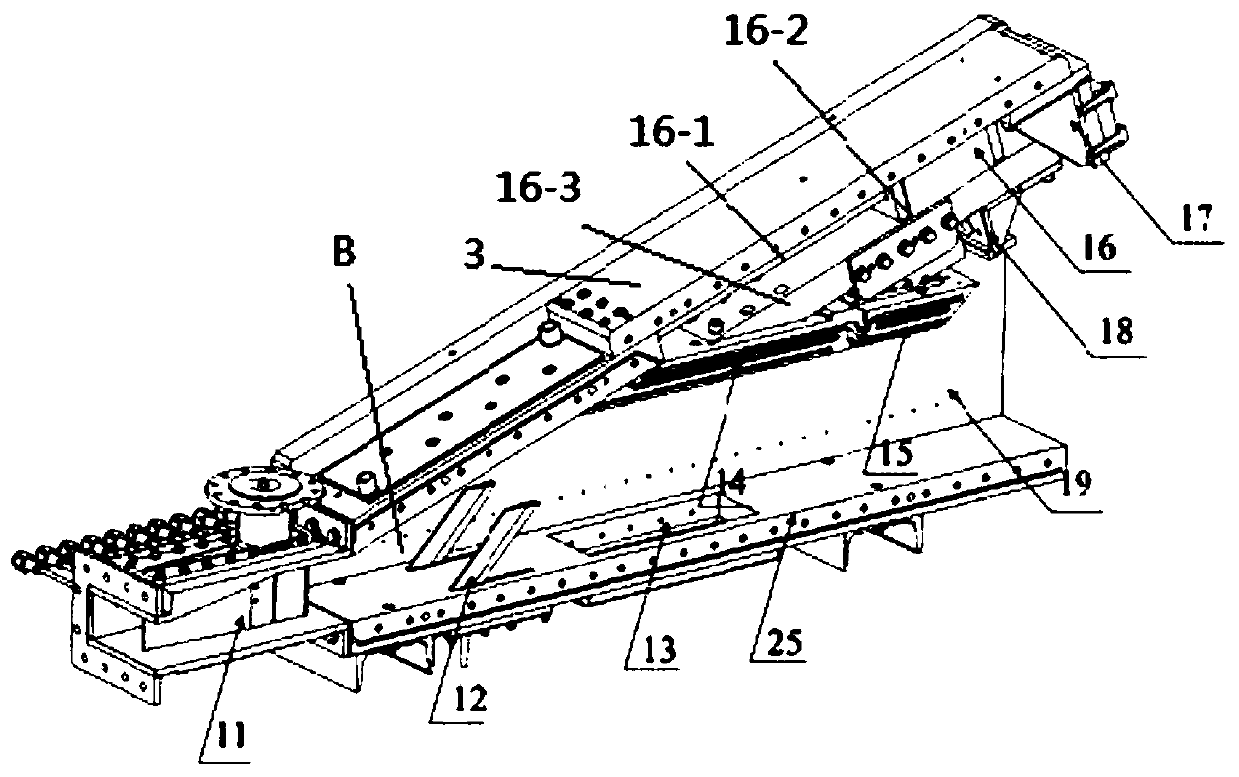

[0030] The present invention is a variable structure rocket-based combined power cycle combustion chamber experimental device, such as figure 1 and 2 As shown, it includes: a combustion chamber isolation section 1, which is a hollow shell open at both ends; and the inner cavity of the hollow shell gradually expands from the inlet end to the outlet end. The upper part of the combustion chamber isolation section 1 is provided with a rocket high-temperature jet inlet 10, which communicates with the high-temperature jet. A pressure measuring seat is also provided on the outer wall of the combustion chamber isolation section 1 for monitoring the pressure therein.

[0031] The expansion section B of the combustion chamber is a hollow shell with open ends, surrounded by the top plate assembly, the side plate 2 and the bottom plate; its front end communicates with the outlet end of the combustion chamber isolation section 1; the longitudinal section of the hollow shell It is a right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com