Movable round bale resilience test bench

A mobile, test-bed technology that can be used in elastic testing, force/torque/work measuring instruments, machine/structural component testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

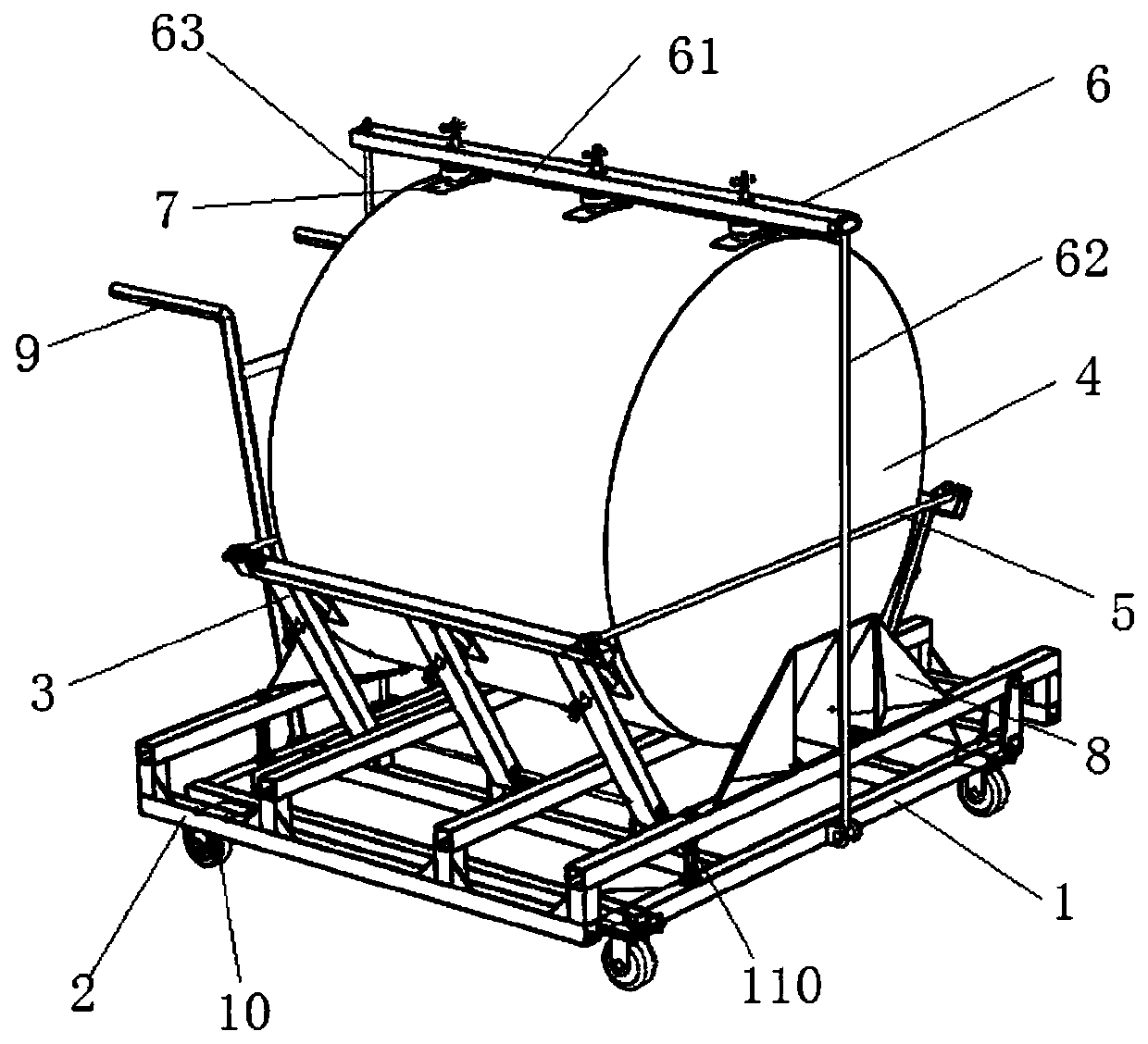

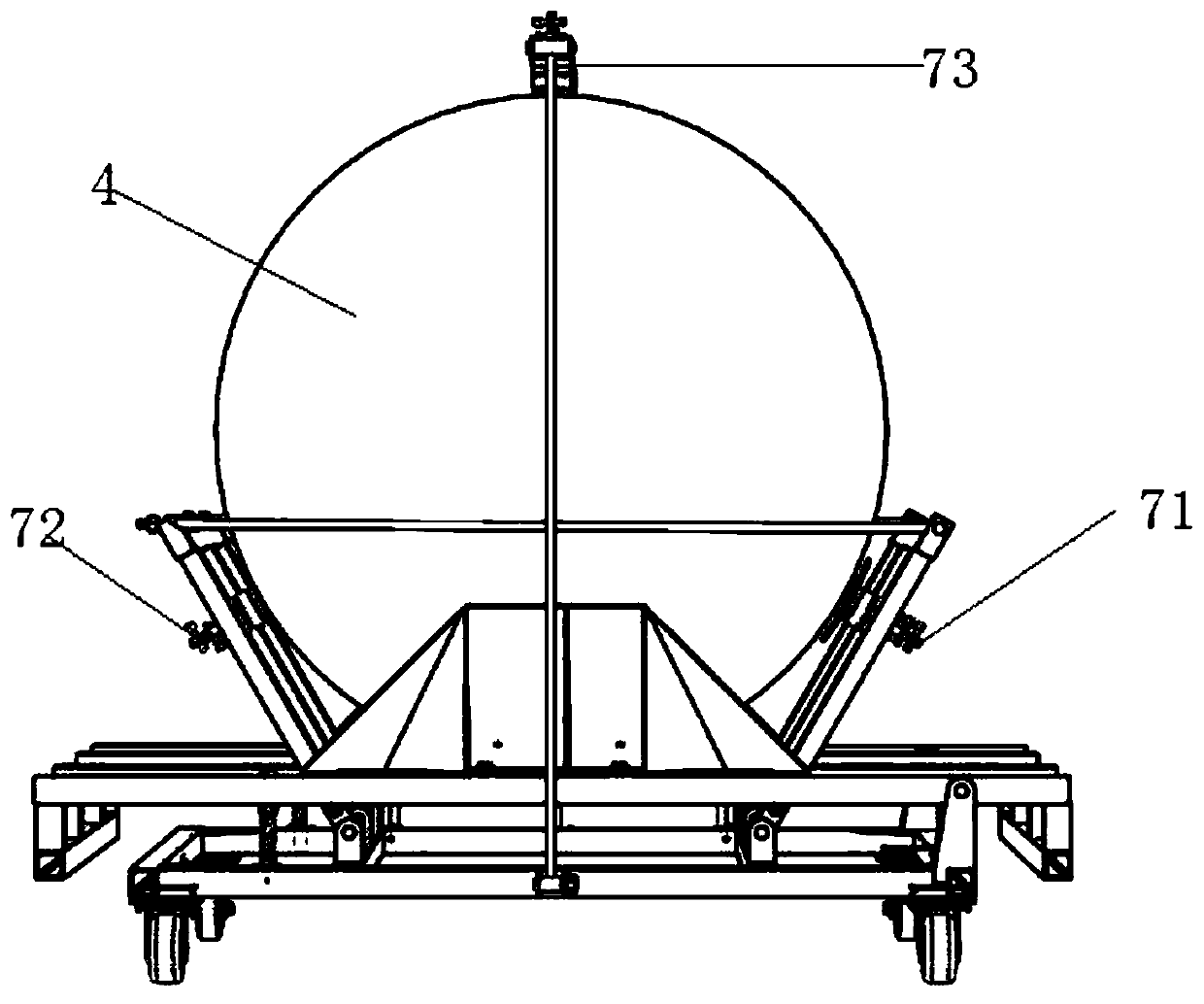

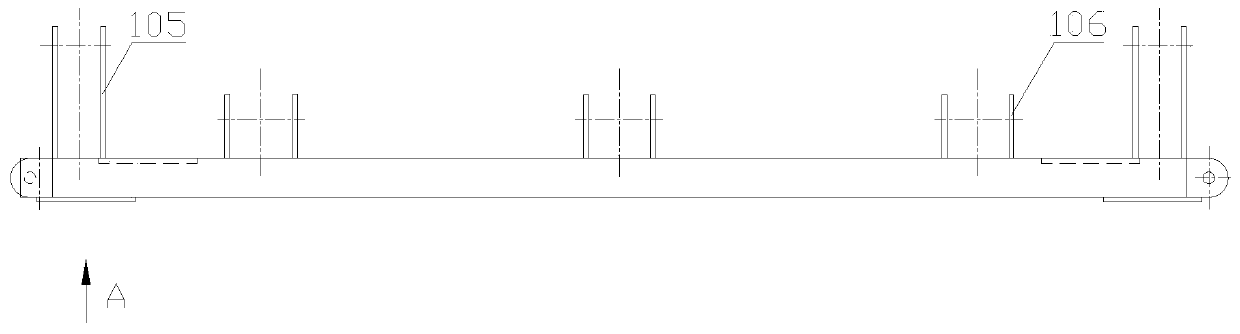

[0074] like figure 1 and 2 As described, a movable round bale resilience test bench is disclosed in the present embodiment, comprising an underframe 1, a turntable 2, an overturn frame 3, a side support 6, a load cell 7 and a guide plate 8; The turntable 2 is rotatably mounted on the underframe 1, and is used to roll the round bales 4 to the ground, and the guide plate 8 is provided with two, which are respectively arranged on both sides of the turnframe 2; Frame 3 comprises left overturning frame and right overturning frame, and described left overturning frame and right overturning frame are arranged on described underframe 1, and are respectively positioned at the both sides of described round bale 4; Described load cell 7 comprises the first A group of 71 load cells, a second group of 72 load cells and a third group of 73 load cells; the first group of load cells and the second group of load cells are respectively arranged on the left and right flip frames The side brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com