Air-jet loom

A technology of air-jet looms and frame boards, which is applied in textiles, textiles, papermaking, and auxiliary equipment for weaving. It can solve problems such as increased humidity, water on the road, and corrosion of workshop frames, so as to reduce warp breakage and strong strength. The effect of enhancing and strengthening protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

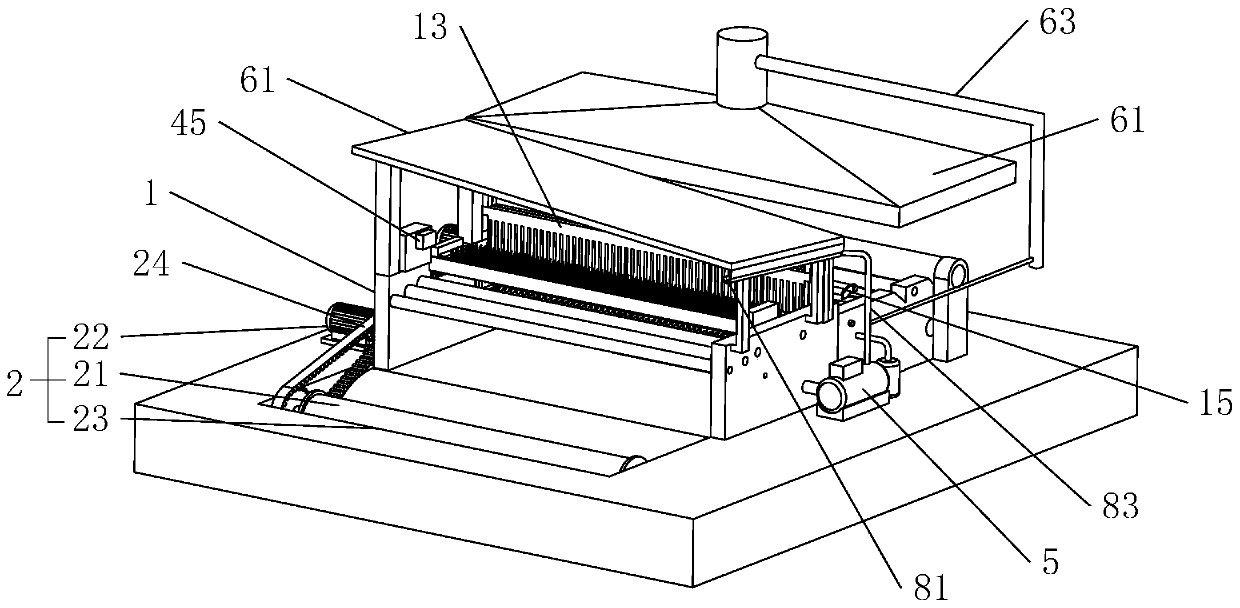

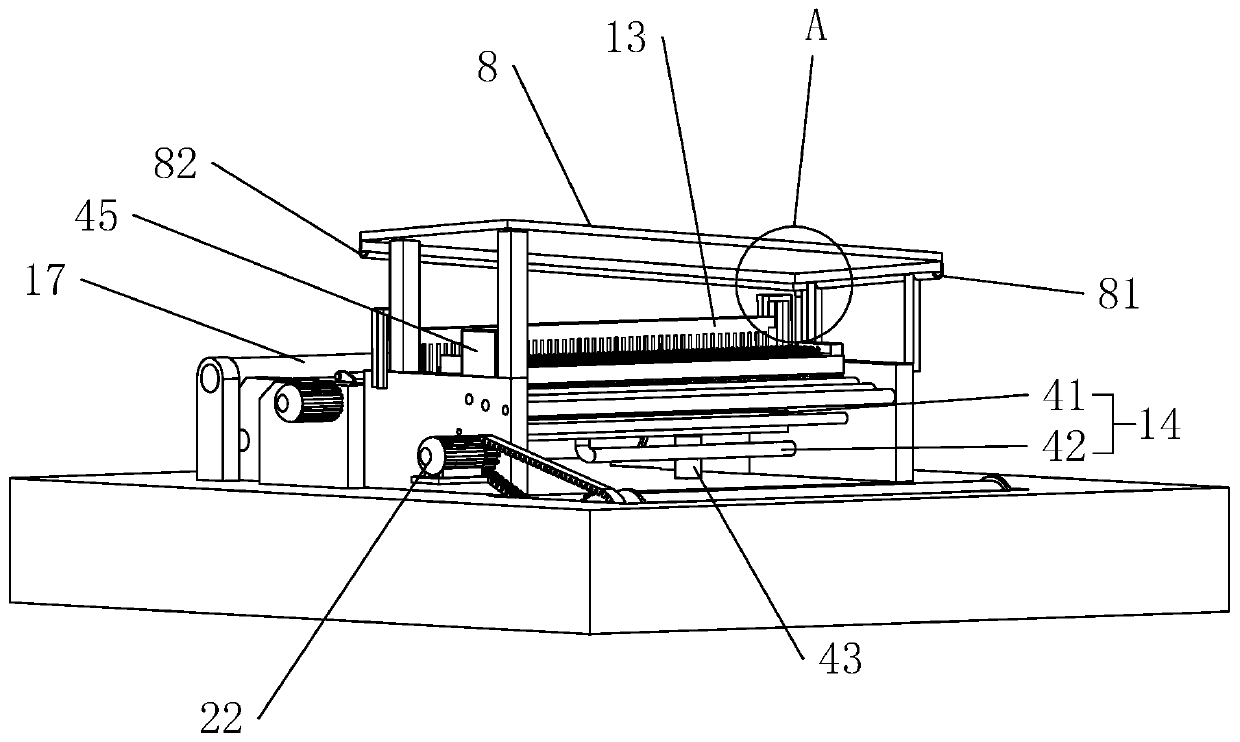

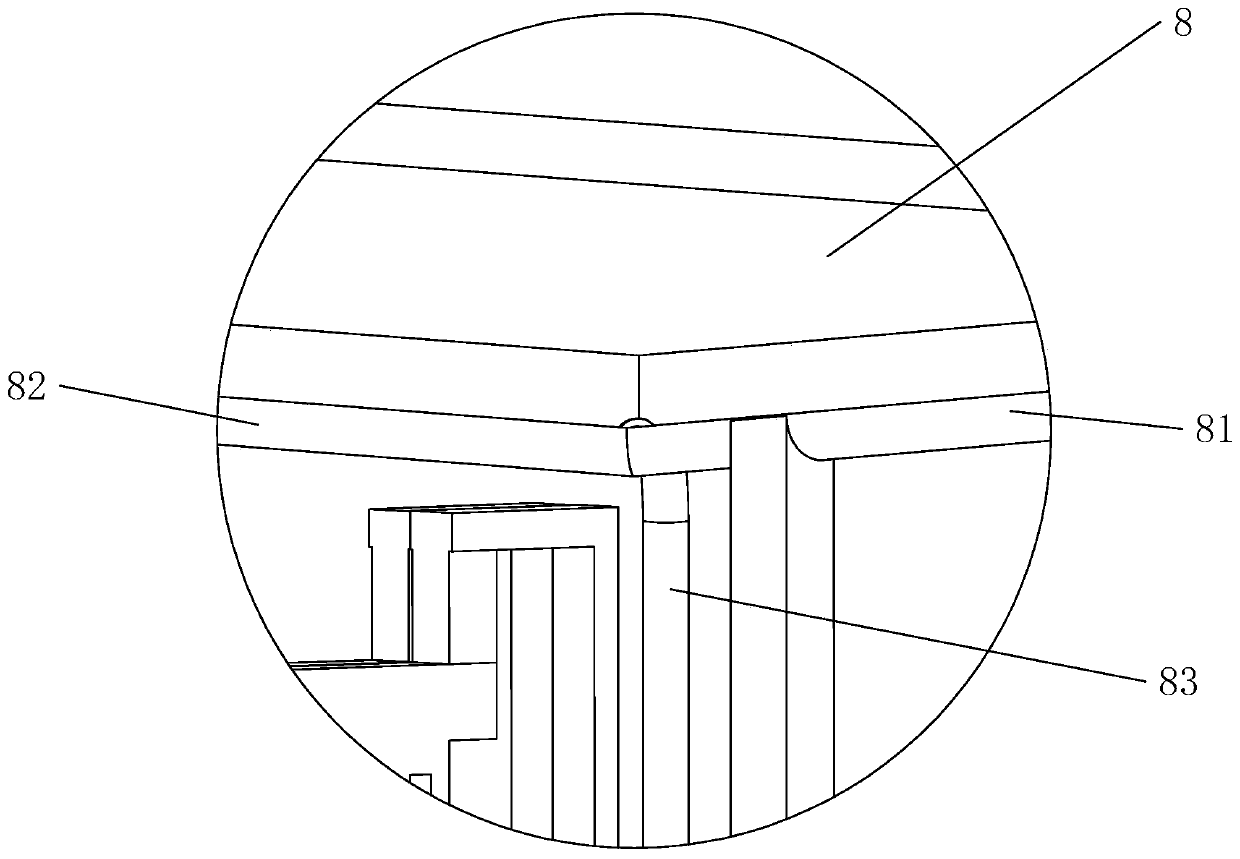

[0038] An air jet loom such as figure 1 , figure 2 , Figure 4 as well as Figure 5 As shown, it includes two rack plates 1 arranged in parallel on the ground, and a warp let-off mechanism 12, an opening mechanism 13, a humidifying mechanism 14, and a beating-up mechanism arranged on the rack plate 1 and distributed sequentially along the length direction of the rack plate 1. Mechanism 15, drying mechanism 16 and coiling mechanism 17.

[0039] Such as figure 1 As shown, the warp let-off mechanism 12 includes a warp beam 21, a warp let-off motor 22 and a foundation pit 23. The foundation pit 23 is set on the ground and is located at the end of the frame plate 1 away from the take-up mechanism 17. The warp beam 21 is rotatably installed in the foundation pit In 23, the warp let-off motor 22 is rotatably mounted on the frame plate 1 and is connected with the warp beam 21 by a toothed pulley 24.

[0040] Such as figure 1 with Figure 4 As shown, the humidifying mechanism 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com