A robot for automatically placing billiards

A technology of robots and billiards, which is applied to billiards, bowling, sports accessories, etc., can solve the problem of large manpower consumption, achieve the effect of saving labor costs and improving the efficiency of swinging balls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

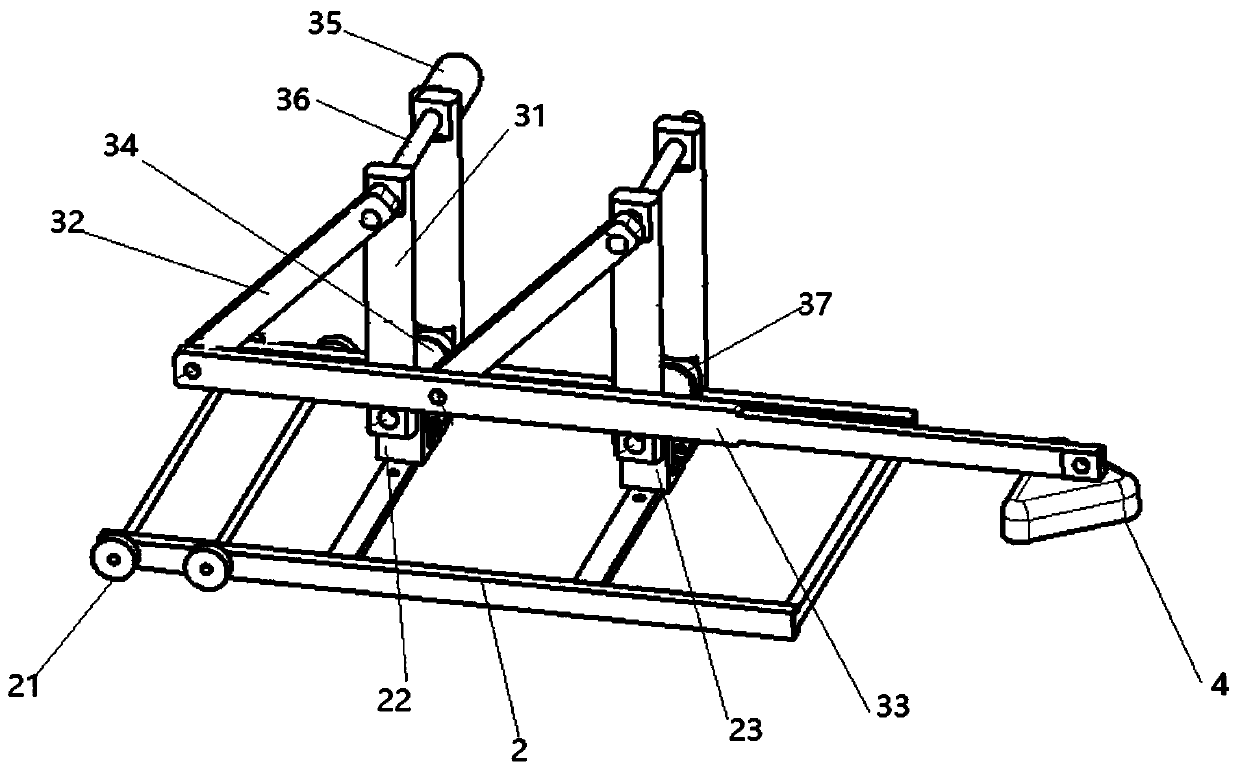

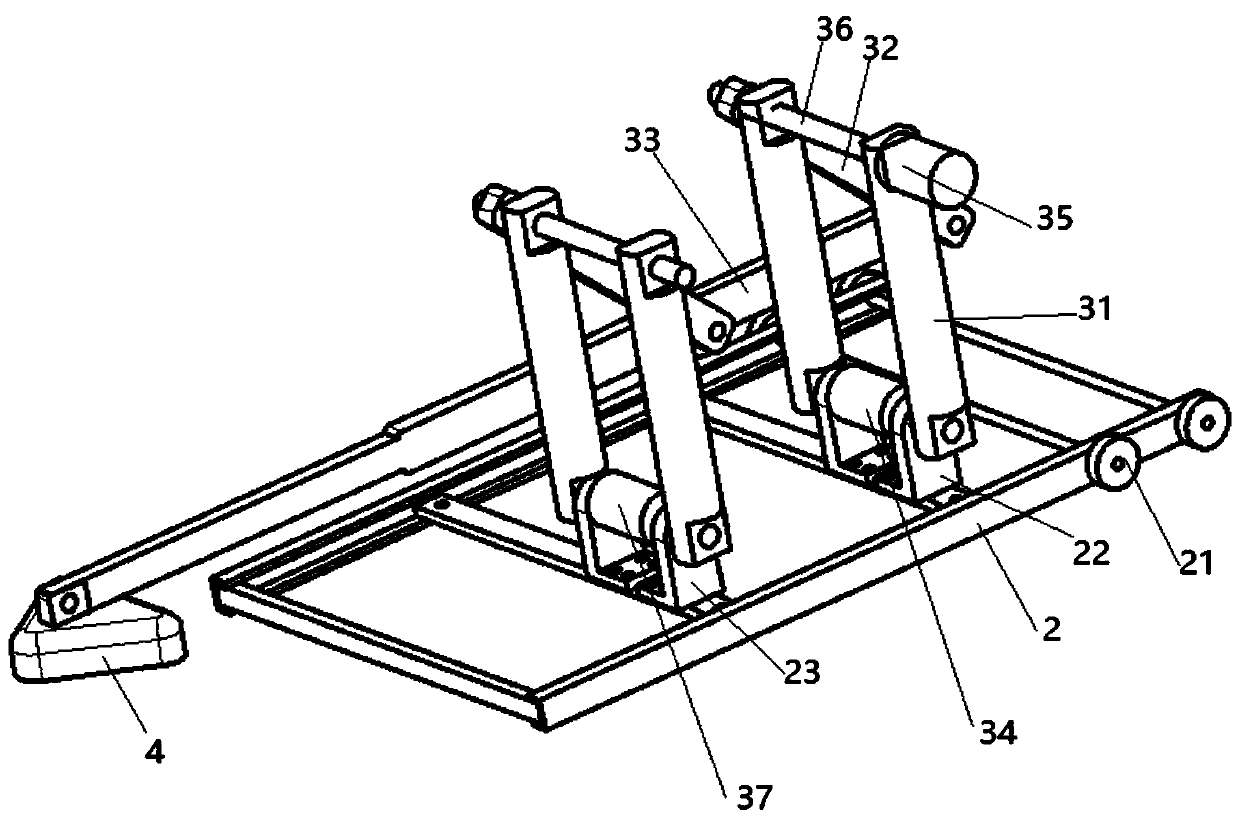

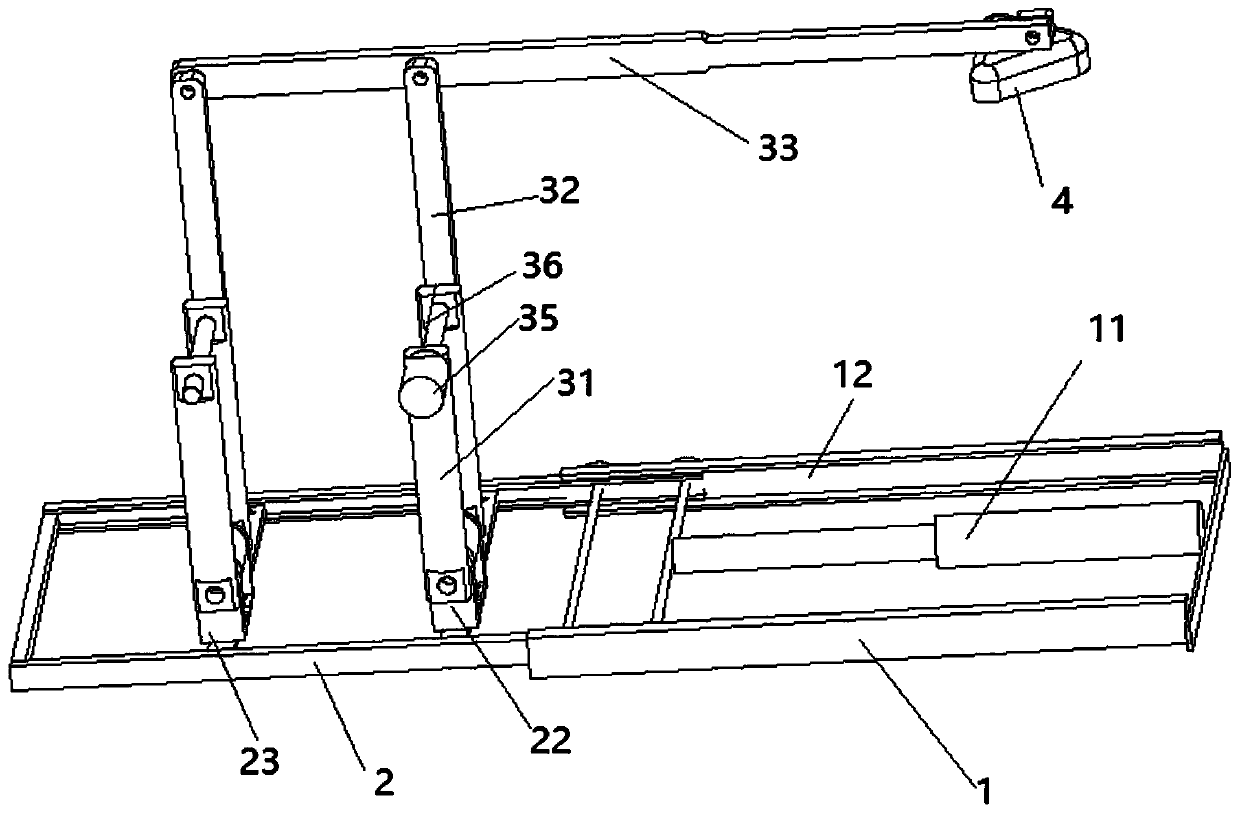

[0033] Please refer to figure 1 and figure 2 , the present embodiment provides a robot for automatically placing billiards, which includes a sliding base, a crank linkage mechanism, a driving mechanism and a ball frame 4 . The robot is usually installed on the bottom of the billiard table 5, does not take up space and does not affect the appearance. After each round of billiards is played, it starts its work, and the driving mechanism is connected with the sliding base. The sliding base slides and drives the crank linkage mechanism to move along the first direction, so that the crank linkage mechanism protrudes from the bottom of the table, and then the driving mechanism continues to work to drive the crank linkage mechanism to move, driving the ball frame installed at its end to move, so that It protrudes from the bottom of the ball table 5 and rotates to a position higher than the ball table 5, and then the driving mechanism drives the sliding base to slide, so that the cr...

Embodiment 2

[0043] This embodiment provides a billiard table. The billiard table placement robot provided in the above embodiment 1 is installed on the bottom of the billiard table. When using the billiard table, the robot can complete the automatic placement of billiard balls. The whole process does not require manual participation, which saves labor costs and improves the efficiency of swinging the ball.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com