Water-leaking preventing method and device of constant temperature and humidity machine

A constant temperature and humidity machine, anti-leakage technology, applied in the direction of measuring devices, lubrication indicator devices, heating methods, etc., can solve problems such as equipment short circuit, non-existence of anti-leakage devices, failure of constant temperature and humidity machines, etc., to avoid water leakage and guarantee The effect of normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

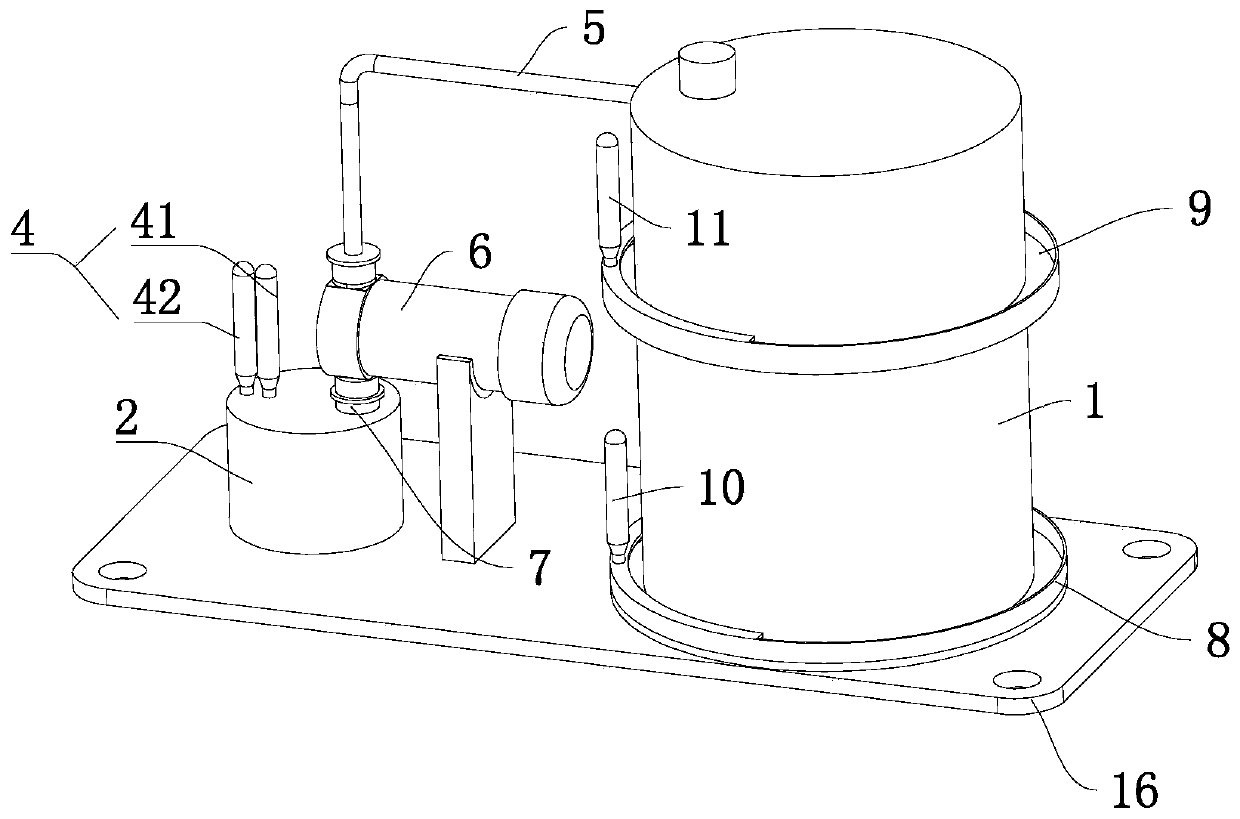

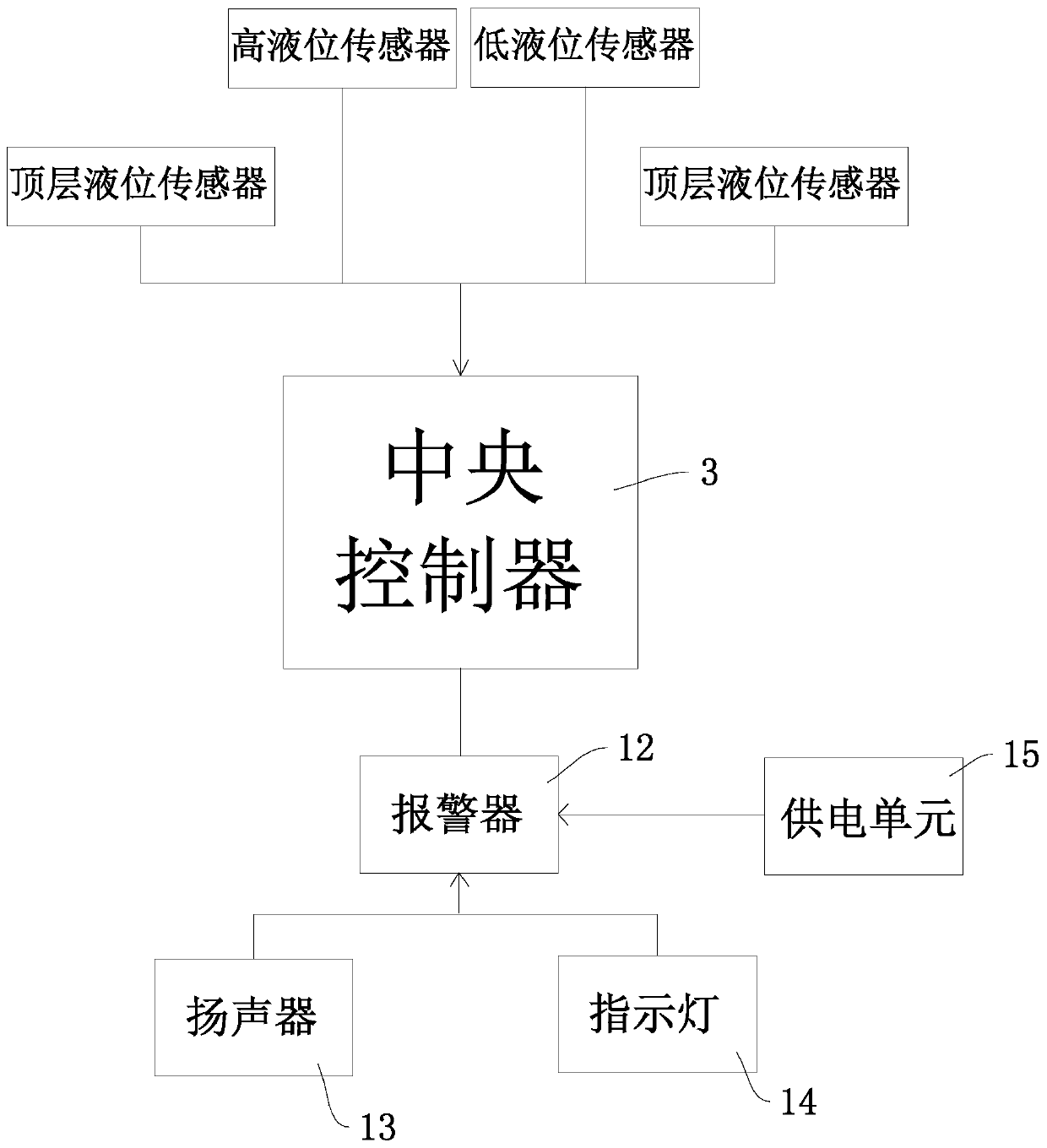

[0040] Embodiment 1: A kind of anti-leakage device of constant temperature and humidity machine, such as figure 1 , figure 2 and image 3 Shown, the bottom in the anti-leakage device is the support seat 16 supporting the second water storage tank 2 and the first water storage tank 1, the second water storage tank 2 is fixed on one side of the support seat 16 top, the first water storage tank 1 It is fixed on the other side of the top of the support seat 16, and one side of the top of the second water storage tank 2 is provided with a second water storage tank 2 detection mechanism.

[0041] Such as figure 1 , figure 2 and image 3 As shown, the detection mechanism of the second water storage tank 2 is composed of a high liquid level sensor 42 and a low liquid level sensor 41. One side of the water storage tank 1, the bottom end of the high liquid level sensor 42 is close to the top of the second water storage tank 2, the bottom end of the low liquid level sensor 41 is c...

Embodiment 2

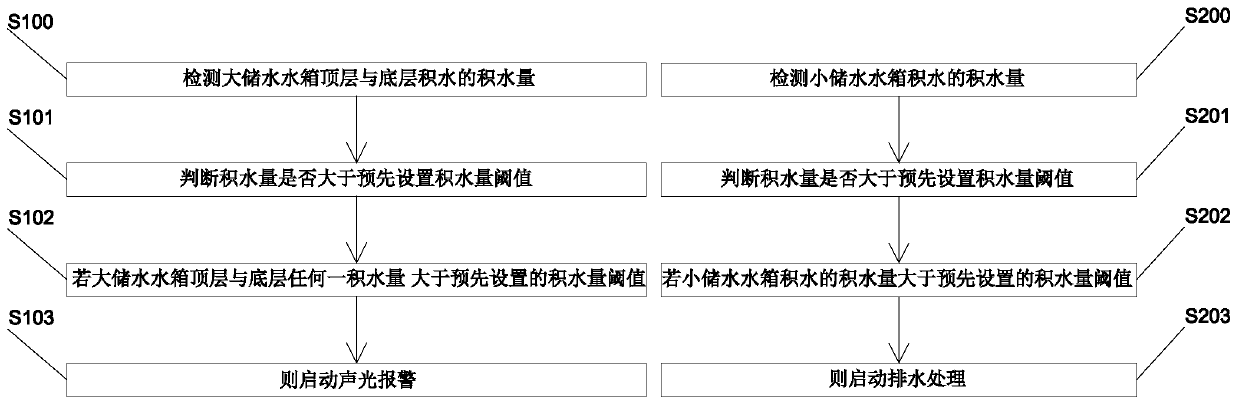

[0047] Embodiment 2: A water leakage prevention method for a constant temperature and humidity machine, which can detect the amount of accumulated water in the second water storage tank 2 and the first water storage tank 1 respectively, and detect the degree of accumulated water at the bottom of the first water storage tank 1 If the bottom water volume is greater than the bottom water volume threshold, the central controller 3 sends a signal to the alarm 12, and simultaneously drives the speaker 13 and Indicator lamp 14 sends an alarm, and at the same time, detects the accumulated water volume at the top layer of the first water storage tank 1, and judges whether the accumulated water volume in the top layer reaches the preset water volume liquid level; threshold, then the central controller 3 sends a signal to the alarm 12, and simultaneously drives the loudspeaker 13 and the indicator light 14 to send an alarm.

[0048] Detect the accumulated water volume of the second water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com