Steamed bun packaging machine and packaging method

A packaging machine and steamed bun technology, applied in the field of steamed bun packaging, can solve the problems of low packaging efficiency of steamed buns and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing, further elaborate the present invention.

[0037] The orientations involved in this manual are all based on the orientation of the steamed bun packaging machine of the present invention when it is in normal operation, and are not limited to its orientation during storage and transportation. They only represent relative positional relationships, not absolute positional relationships.

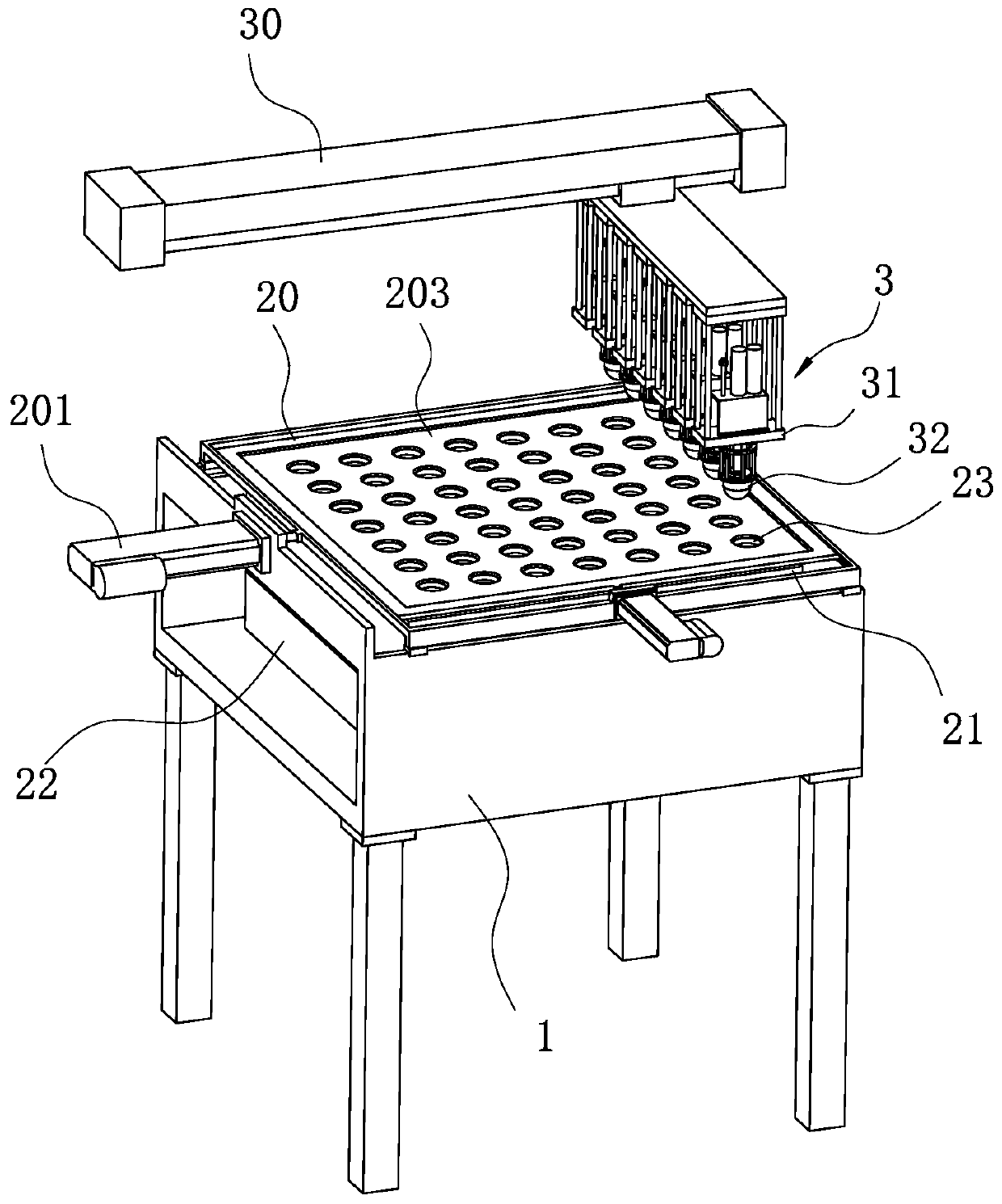

[0038] Such as figure 1 As shown, a steamed bun packaging machine includes a bracket 1, a film-forming component 2 is installed on the bracket 1, a mounting frame 31 is arranged above the film-forming component 2, and the mounting frame 31 is connected to the bracket 1, and the mounting frame 31 passes through the first A planar movement mechanism 30 is connected to the lamination assembly 3, and the first planar movement mechanism 30 drives the lamination assembly 3 to move in the horizontal plane.

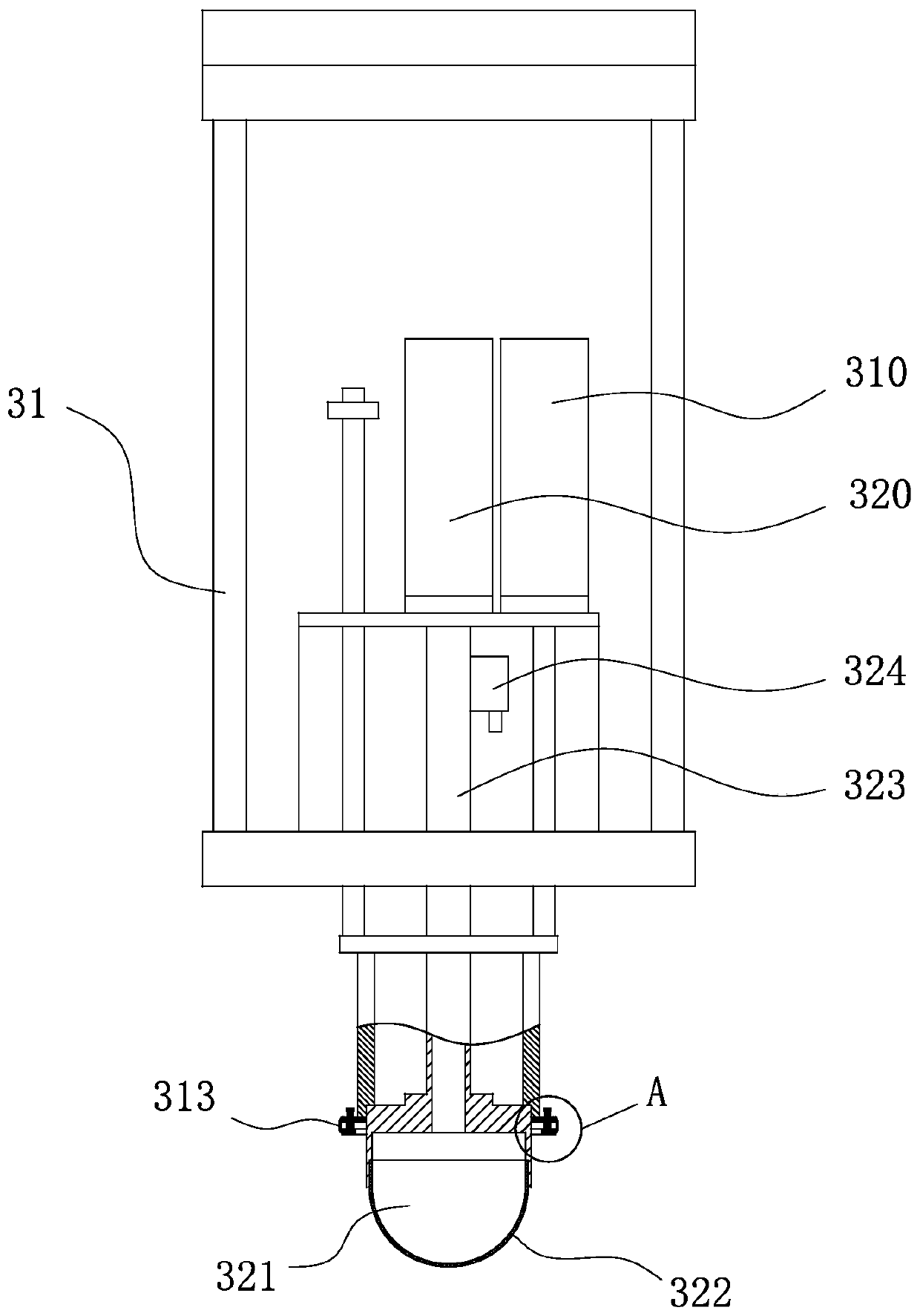

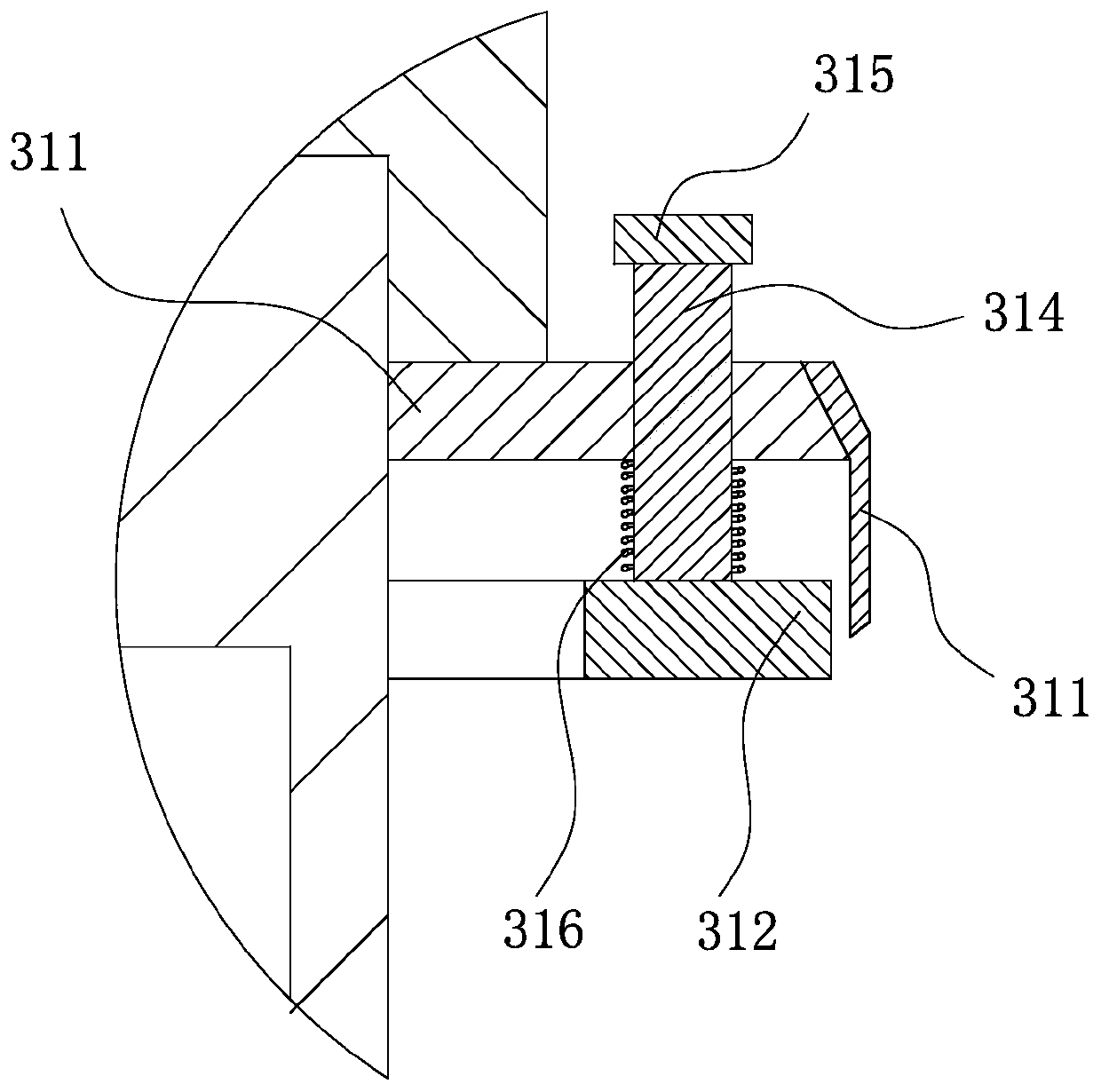

[0039] Such as Figure 4 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com