Low-resistance synchronous direct-acting type double-flapping-wing aircraft

A flapping-wing aircraft and direct-moving technology, applied to aircraft, unmanned aircraft, wings, etc., can solve the problem of inability to achieve vertical take-off and landing and hovering in the air, restricting the popularization and application of flapping-wing aircraft, and flapping-wing aircraft Low overall efficiency and other issues, to achieve the effect of simple structure, low production cost, and flapping wings synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

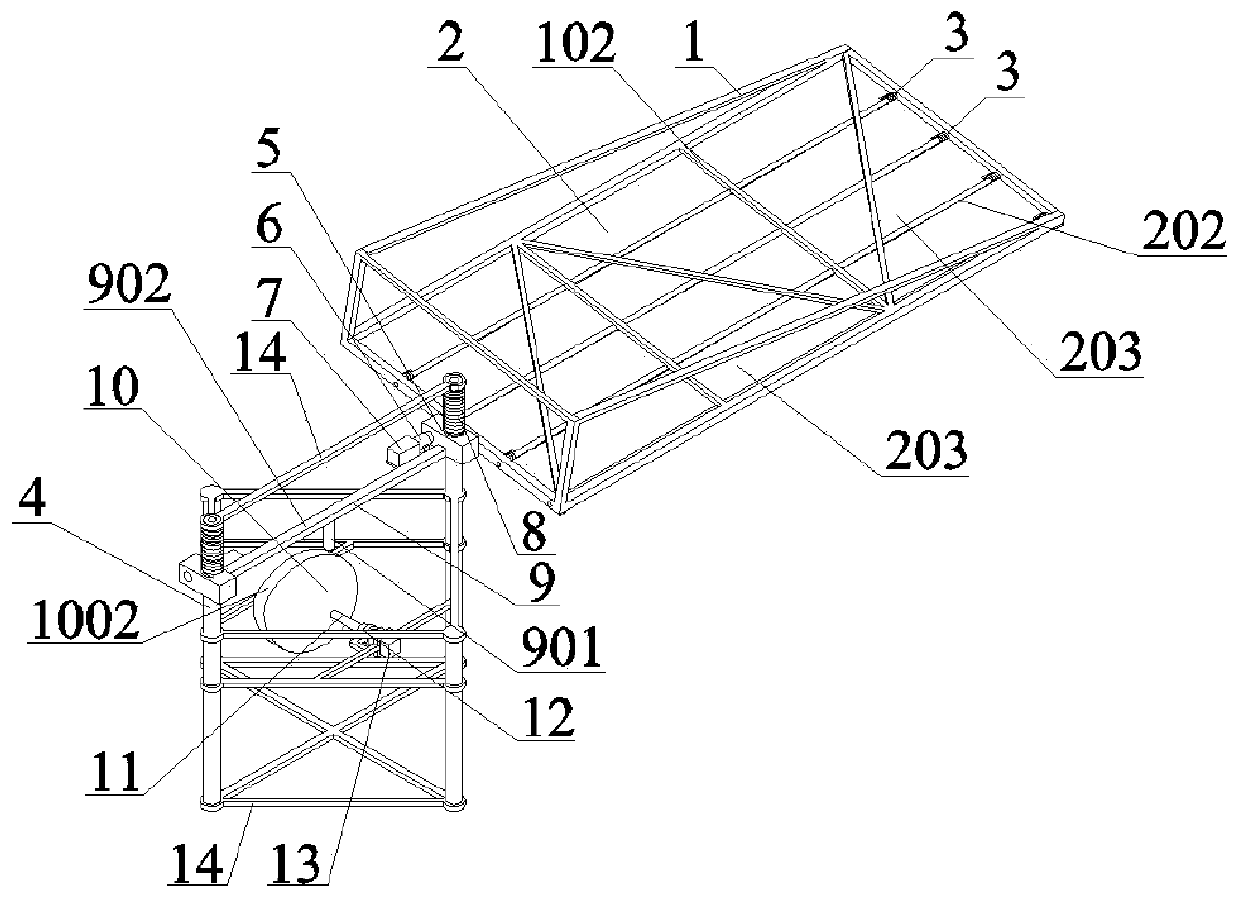

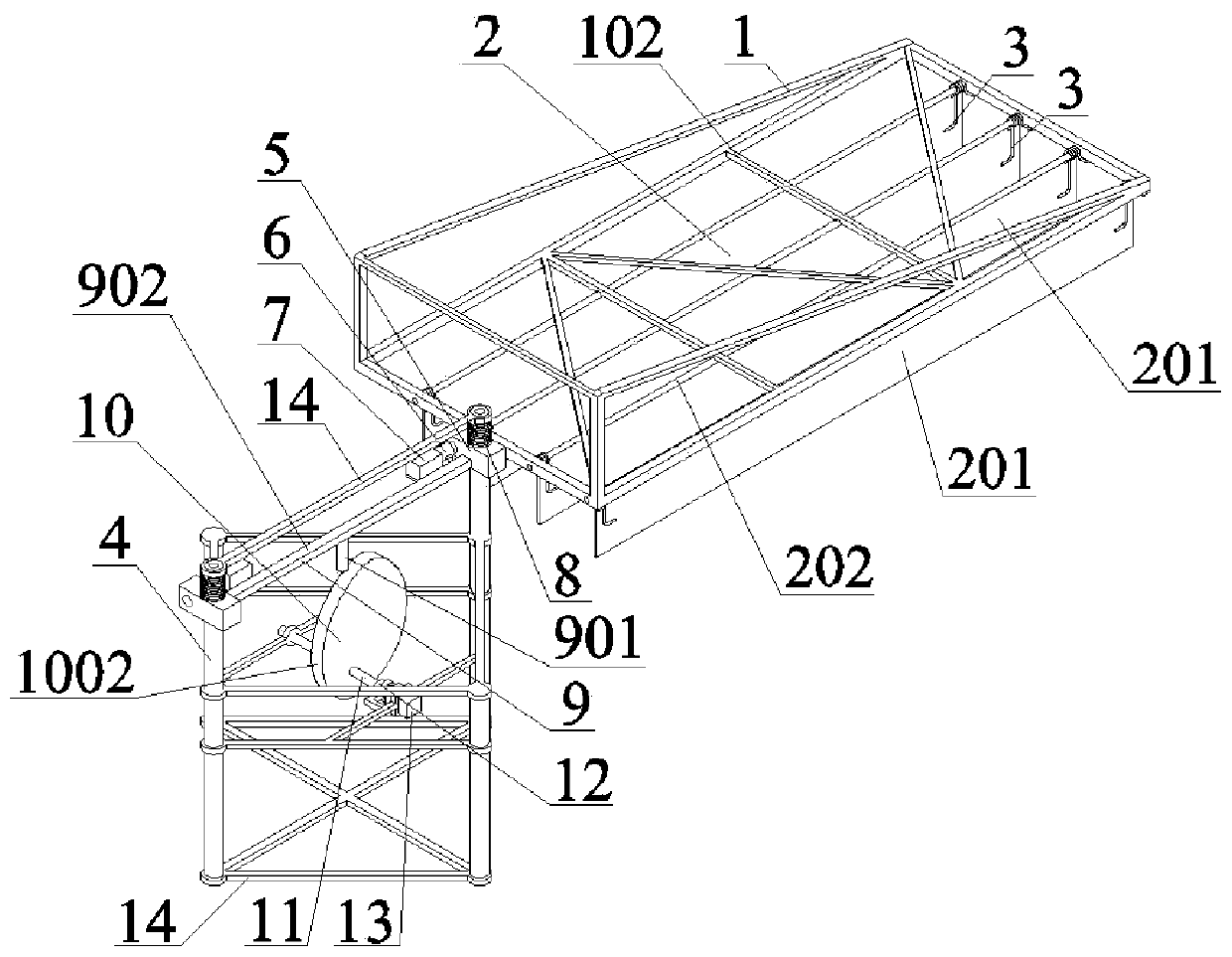

[0041] to combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 , a high-voltage wire inspection drone using a low-resistance synchronous direct-acting double flapping wing aircraft. Such as figure 1 As shown, the low-resistance synchronous direct-acting double flapping-wing aircraft includes flapping-wing frame 1, blade 2, torsion spring 3, slideway 4, connector 5, first reducer 6, stepper motor 7, spring 8, push rod 9. Cam 10, transmission shaft 11, second reducer 12, motor 13 and fuselage frame 14, blade installation hole 101, blade limit beam 102 and flapping wing shaft 103 are arranged on flapping wing frame 1, and blades are arranged on blade 2 On the windward side 201, blade shaft 202 and blade leeward side 203, there are slideway holes 501 and flapping wing shaft holes 502 on the connector 5, the axis of the slideway holes 501 is perpendicular to the axis of the flapping wing shaft holes...

Embodiment 2

[0043] This embodiment 2 provides a special drone for high-rise fire extinguishing, its structure is the same as that of embodiment 1, the difference is: the number of blades 2 in each flapping wing frame 1 is 6, the blade limit beam 102, the strengthening vertical beam 104 , Strengthening beam 105 and strengthening inclined beam 106 all adopt engineering plastics. It is a high-rise fire-fighting special UAV using a low-resistance synchronous direct-acting dual flapping wing aircraft. Including flapping wing frame 1, blade 2, torsion spring 3, slideway 4, connector 5, first reducer 6, stepping motor 7, spring 8, push rod 9, cam 10, transmission shaft 11, second reducer 12. The motor 13 and the fuselage frame 14, the flapping wing frame 1 has a blade installation hole 101, a blade limit beam 102 and a flapping wing shaft 103, and the blade 2 has a blade windward side 201, a blade shaft 202 and a blade leeward side 203, A slideway hole 501 and a flapping wing shaft hole 502 are...

Embodiment 3

[0045] This embodiment 2 provides an agricultural plant protection unmanned aerial vehicle, its structure is the same as embodiment 1, the difference is: the number of blades 2 in each flapping wing frame 1 is 8, the blade limit beam 102, the strengthening vertical beam 104, Both the reinforcing beam 105 and the reinforcing inclined beam 106 are made of engineering plastics. An agricultural plant protection UAV using a low-resistance synchronous direct-acting double flapping wing aircraft. Including flapping wing frame 1, blade 2, torsion spring 3, slideway 4, connector 5, first reducer 6, stepping motor 7, spring 8, push rod 9, cam 10, transmission shaft 11, second reducer 12. The motor 13 and the fuselage frame 14, the flapping wing frame 1 has a blade installation hole 101, a blade limit beam 102 and a flapping wing shaft 103, and the blade 2 has a blade windward side 201, a blade shaft 202 and a blade leeward side 203, A slideway hole 501 and a flapping wing shaft hole 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com