Eccentric arc-shaped ring corridor segment high-altitude lifting tool and lifting method thereof

A ring corridor and arc-shaped technology, which is applied in the direction of lifting devices, lifting frames, auxiliary devices, etc., can solve the problems of inability to form butt joint welding, eccentric deflection of eccentric arc ring corridor sections, and inability to adjust attitude at high altitudes. It achieves simple structure, High installation efficiency and smooth connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

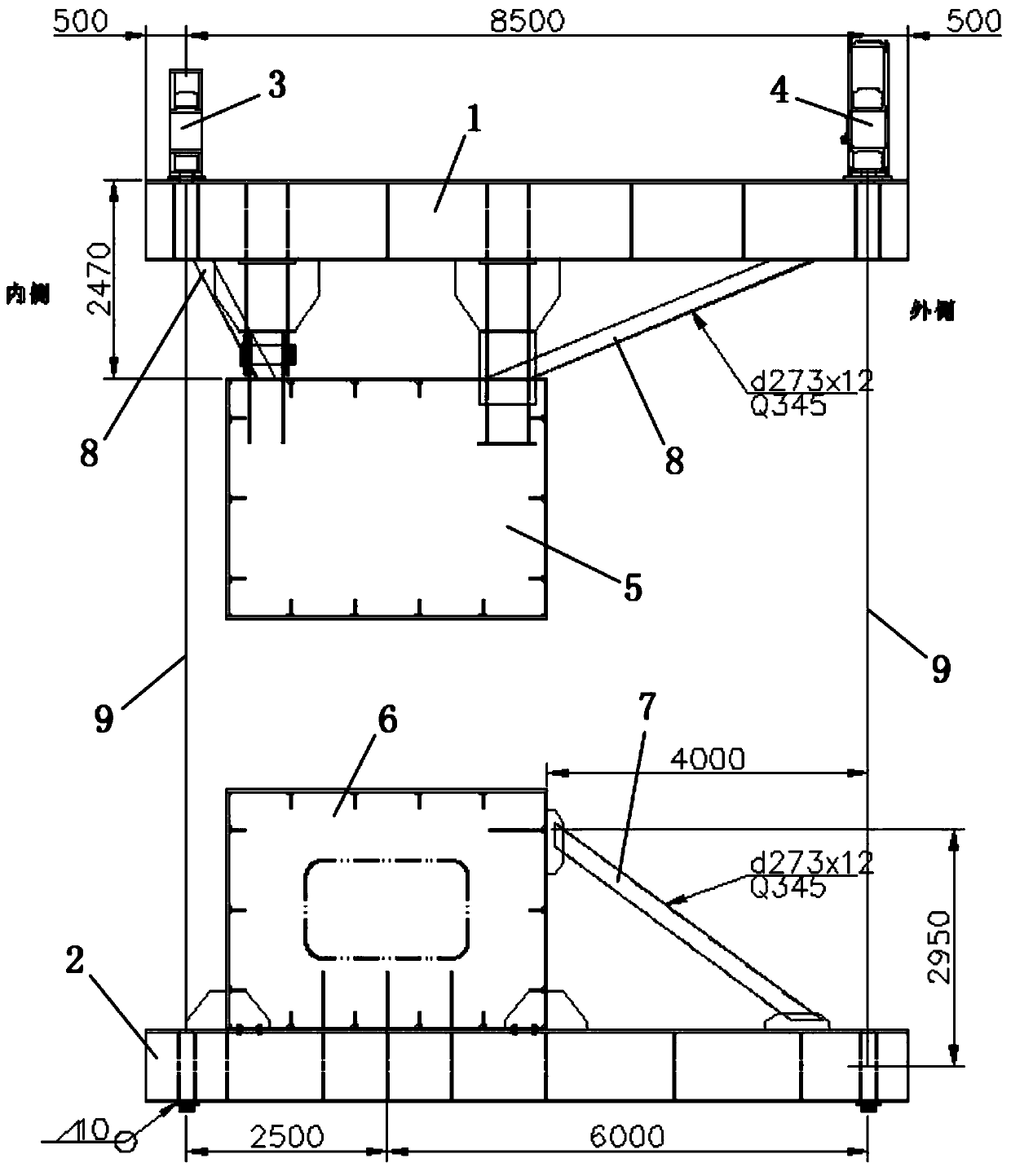

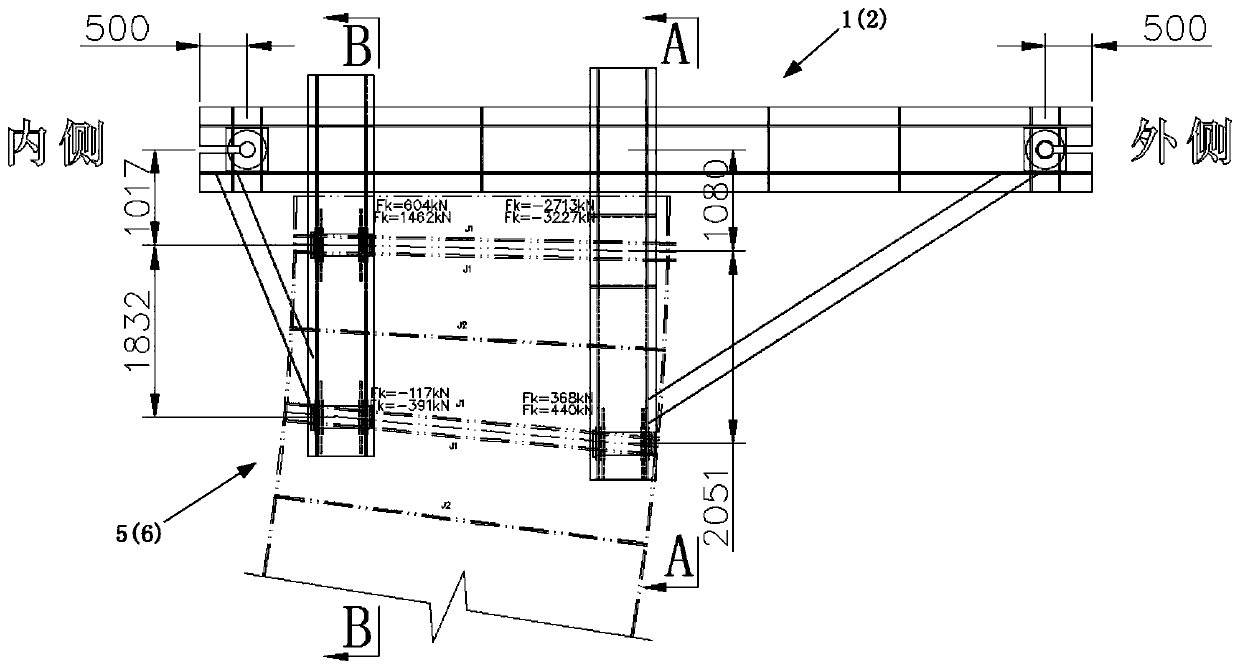

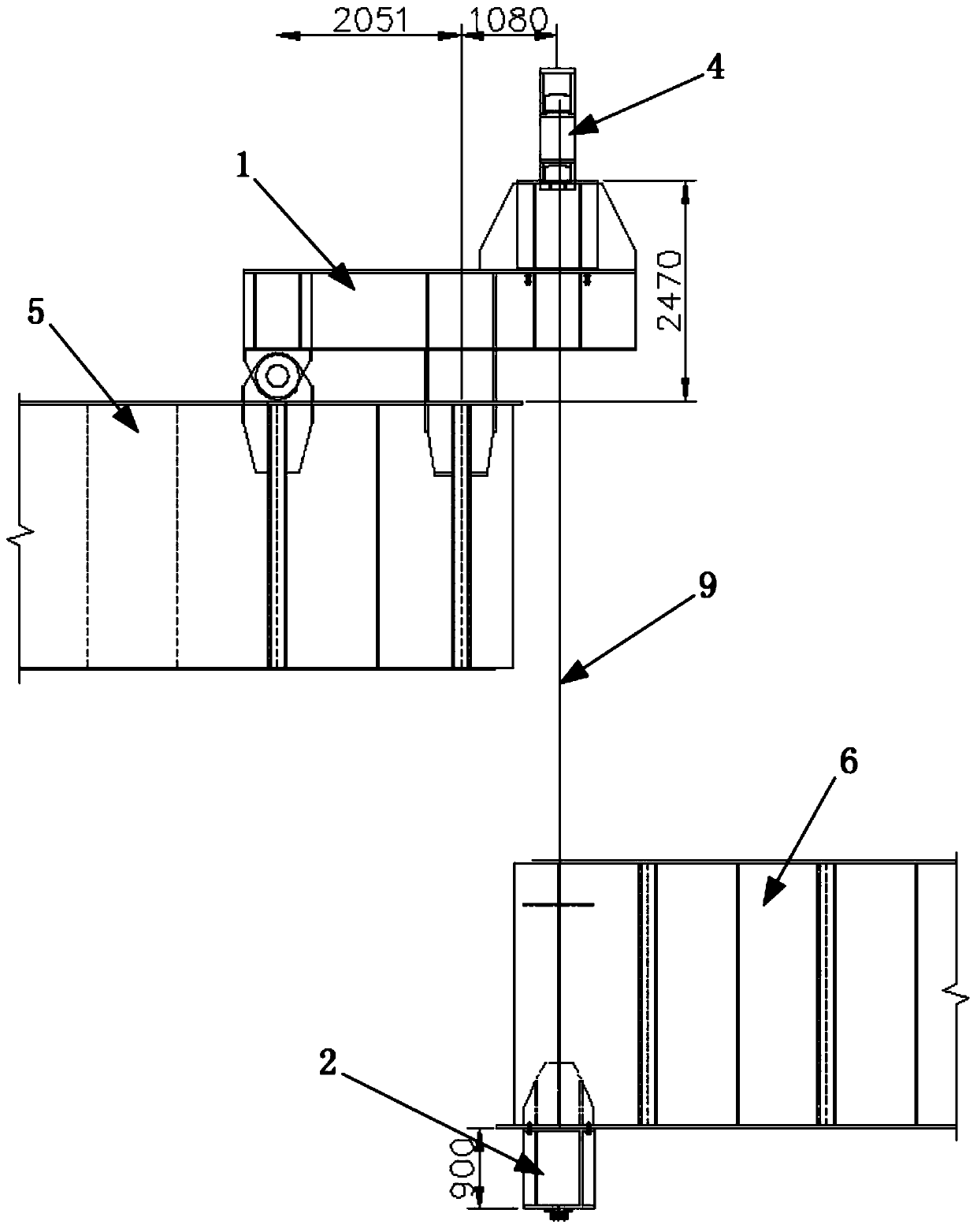

[0028] like Figure 1-4 As shown, the high-altitude lifting tooling for the eccentric arc-shaped ring corridor section provided by the present invention has a simple structure, scientific and reasonable design, and is easy to use. To ensure that the eccentric arc ring section does not deflect during lifting, to ensure the safety of the lifting process, and after the lifting is in place, the joints are connected smoothly, the welding is convenient, and the installation efficiency is improved. The present invention is used to elevate the eccentric arc-shaped ring corridor section 6 located on the ground in the segmented high-altitude ring corridor to a height of 100m, and separate its two ends from the high-altitude arc-shaped ring corridor section fixed at an altit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com