Fuel cell assembling device and method

A fuel cell and assembly device technology, applied in fuel cells, circuits, electrical components, etc., can solve problems such as poor airtight effect, affecting the performance and service life of the stack, and large deviation of sealing and matching, so as to improve performance and service life , shorten the assembly and test cycle, and the effect of small deviation of sealing fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

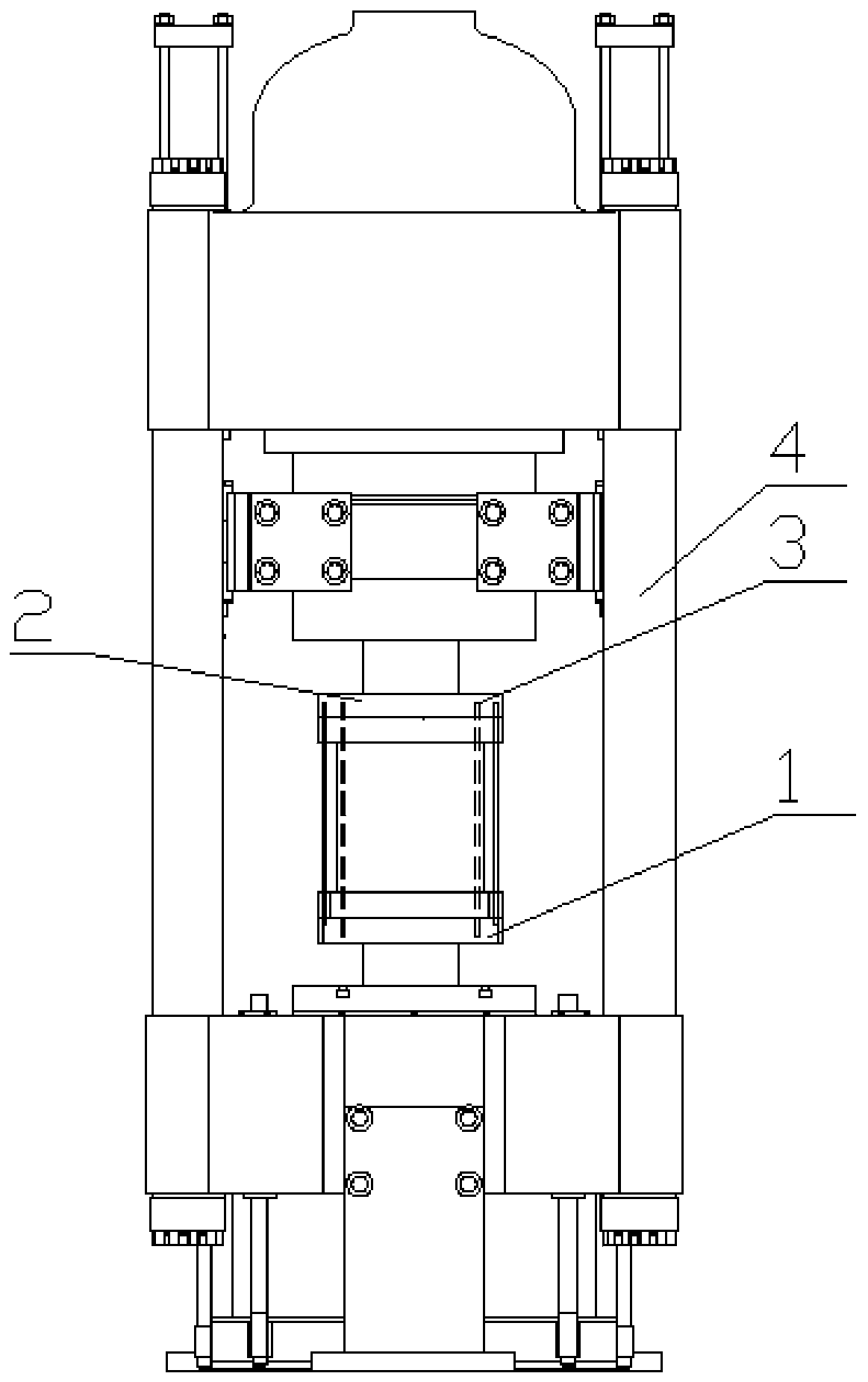

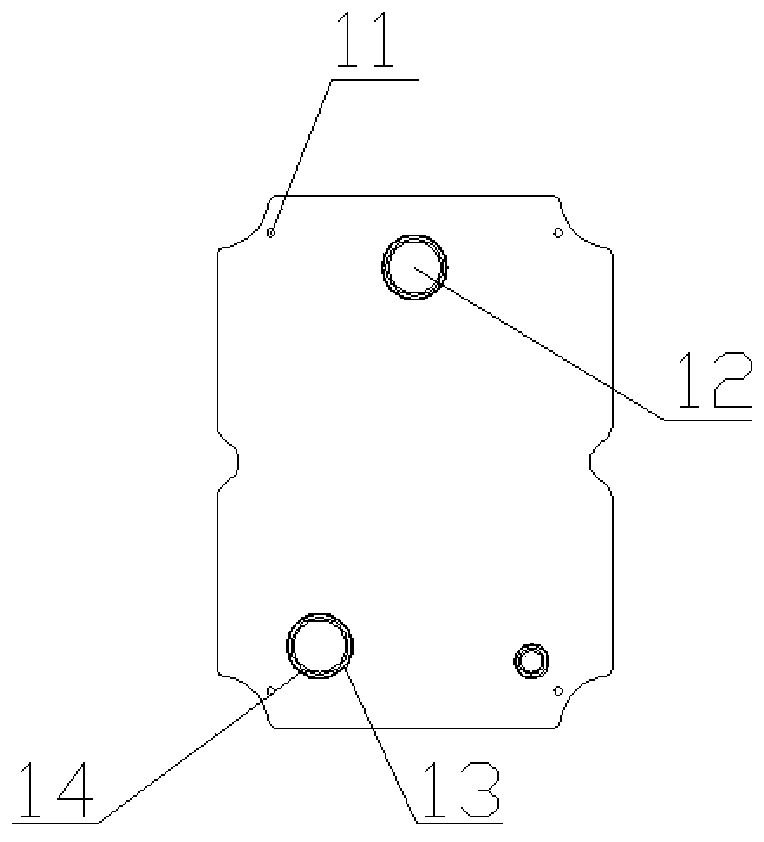

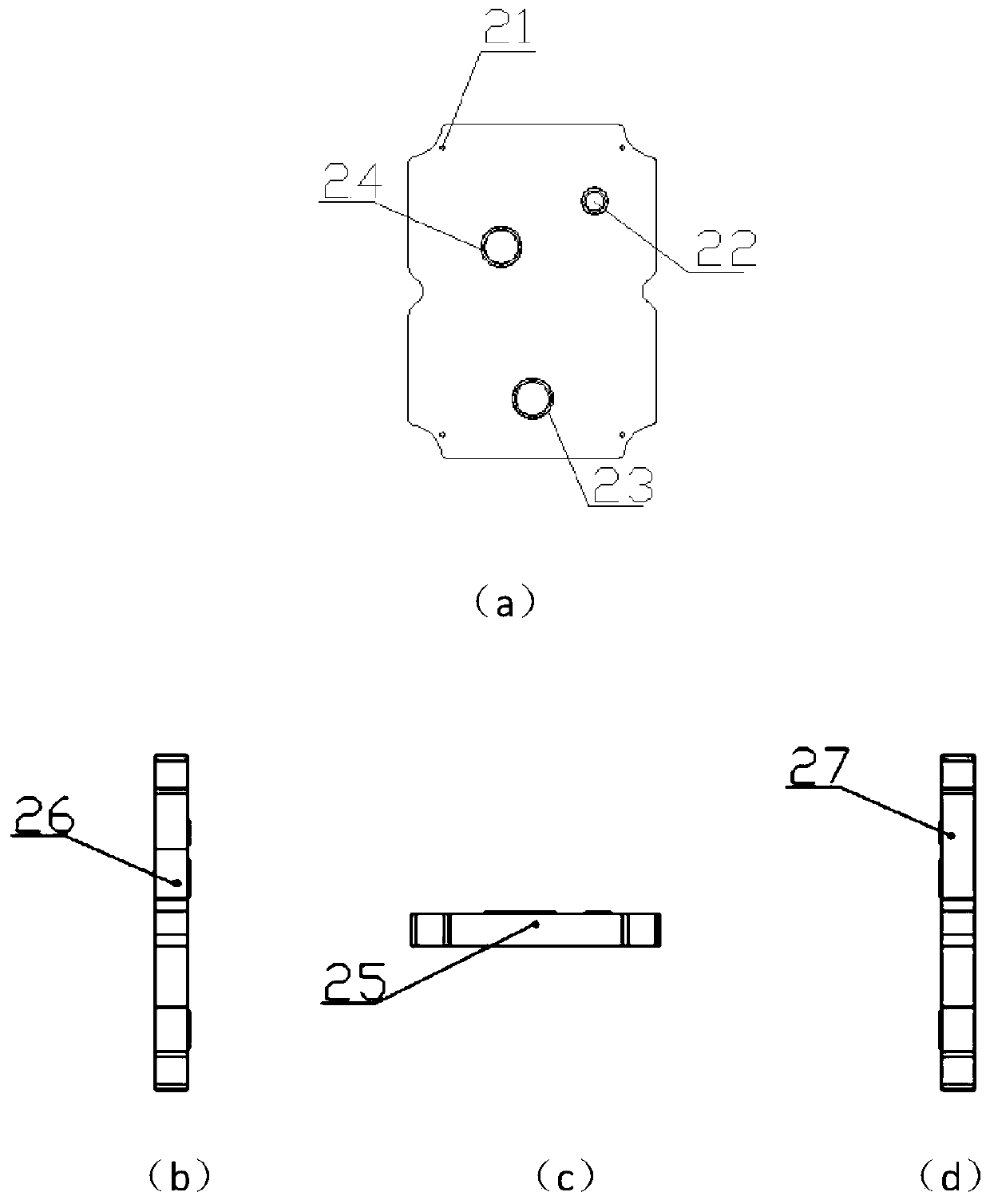

[0069] Take the fuel cell stack assembled with 100 single cells as an example.

[0070] Firstly, align and fix the lower press-fit plate 1 on the fixed lower press head of the YTK32-8 press, install the inner positioning tool 3 on the lower press-fit plate, and place the lower end plate of the fuel cell stack on the lower press-fit plate 1 First, pass the inner positioning tool 3 through the assembly positioning holes at the four corners of the lower end plate of the fuel cell stack, and press the lower buffer plate, lower conductive plate, cell stack monomer, upper conductive plate, upper buffer plate, upper end plate, etc. The sequence is neatly stacked on the inner positioning tool 3, and finally the upper press-fit plate 2 is placed on the upper end plate, and a press-fit force of 30kN is applied to the upper press-fit plate 2 and the fuel cell stack in the upper press-fit plate 2 by a press. Apply torque to the target value of 10KN on the stack rods and fasteners; the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com