Method for preparing durable fabric with electromagnetic shielding performance through superhydrophobic finishing

An electromagnetic shielding and hydrophobization technology, which is applied in fiber treatment, plant fiber, textiles and papermaking, etc., can solve the problems such as the washing resistance and stability of electromagnetic shielding fabrics that have not been pointed out, and achieve high electromagnetic shielding efficiency, low production cost, and good conductivity performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

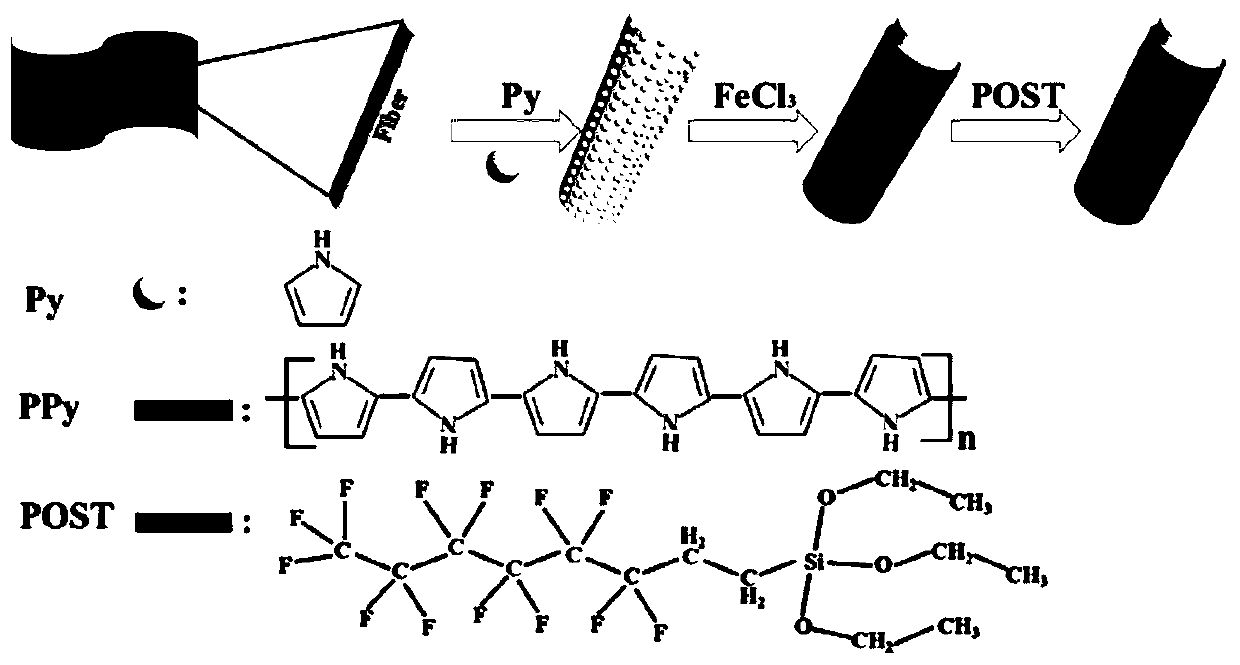

Method used

Image

Examples

Embodiment 1

[0034] Choose ordinary cotton fabric 8×8cm 2 , the thickness is about 0.5mm, and the weight per unit area is 96g / cm 2 , and the durable electromagnetic shielding fabric with superhydrophobic finishing can be prepared according to the following steps.

[0035] Step 1. Soak the cotton fabric in acetone for 15 minutes, take it out and soak it in ethanol for 15 minutes, then wash it repeatedly with deionized water three times to remove oil and impurities on the surface of the fabric, and then dry it at 100°C for use.

[0036] Step 2, put the above-mentioned washed cotton fabric into the pyrrole solution with a concentration of 0.5 mol / L, and soak for 10 min.

[0037] Step 3, put the above-mentioned cotton fabric adsorbed by pyrrole monomer into a sodium dodecylbenzenesulfonate solution with a mass concentration of 10 mg / mL, and soak for 10 min.

[0038] Step 4, put the cotton fabric adsorbed with sodium dodecylbenzenesulfonate into a ferric chloride solution with a concentration...

Embodiment 2

[0045] The cotton fabric sample that present embodiment is selected with embodiment 1 is identical, and difference is that method step parameter is different, and the concrete method step of this embodiment is as follows:

[0046] Step 1. Soak the cotton fabric in acetone for 15 minutes, take it out and soak it in ethanol for 15 minutes, then wash it repeatedly with deionized water three times to remove oil and impurities on the surface of the fabric, and then dry it at 100°C for use.

[0047] Step 2, put the above-mentioned washed cotton fabric into the pyrrole solution with a concentration of 1mol / L, and soak for 10min.

[0048] Step 3, put the above-mentioned cotton fabric adsorbed by pyrrole monomer into a sodium dodecylbenzenesulfonate solution with a mass concentration of 10 mg / mL, and soak for 10 min.

[0049]Step 4, put the cotton fabric adsorbed with sodium dodecylbenzenesulfonate into a ferric chloride solution with a concentration of 1mol / L. At this time, the temper...

Embodiment 3

[0056] The cotton fabric sample that present embodiment is selected with embodiment 1 is identical, and difference is that method step parameter is different, and the concrete method step of this embodiment is as follows:

[0057] Step 1. Soak the cotton fabric in acetone for 15 minutes, take it out and soak it in ethanol for 15 minutes, then wash it repeatedly with deionized water three times to remove oil and impurities on the surface of the fabric, and then dry it at 100°C for use.

[0058] Step 2, put the above-mentioned washed cotton fabric into the pyrrole solution with a concentration of 1mol / L, and soak for 10min.

[0059] Step 3, put the above-mentioned cotton fabric adsorbed by pyrrole monomer into a sodium dodecylbenzenesulfonate solution with a mass concentration of 10 mg / mL, and soak for 10 min.

[0060] Step 4, put the cotton fabric adsorbed with sodium dodecylbenzenesulfonate into a ferric chloride solution with a concentration of 1mol / L, the solution temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com