Label printing equipment and printing technology thereof

A label printing and equipment technology, used in printing, printing machines, rotary printing machines, etc., can solve the problems of waste, ink overflow, and difficulty in controlling the amount of ink added, and achieve the effect of preventing waste, not easy to overflow, and easy to control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

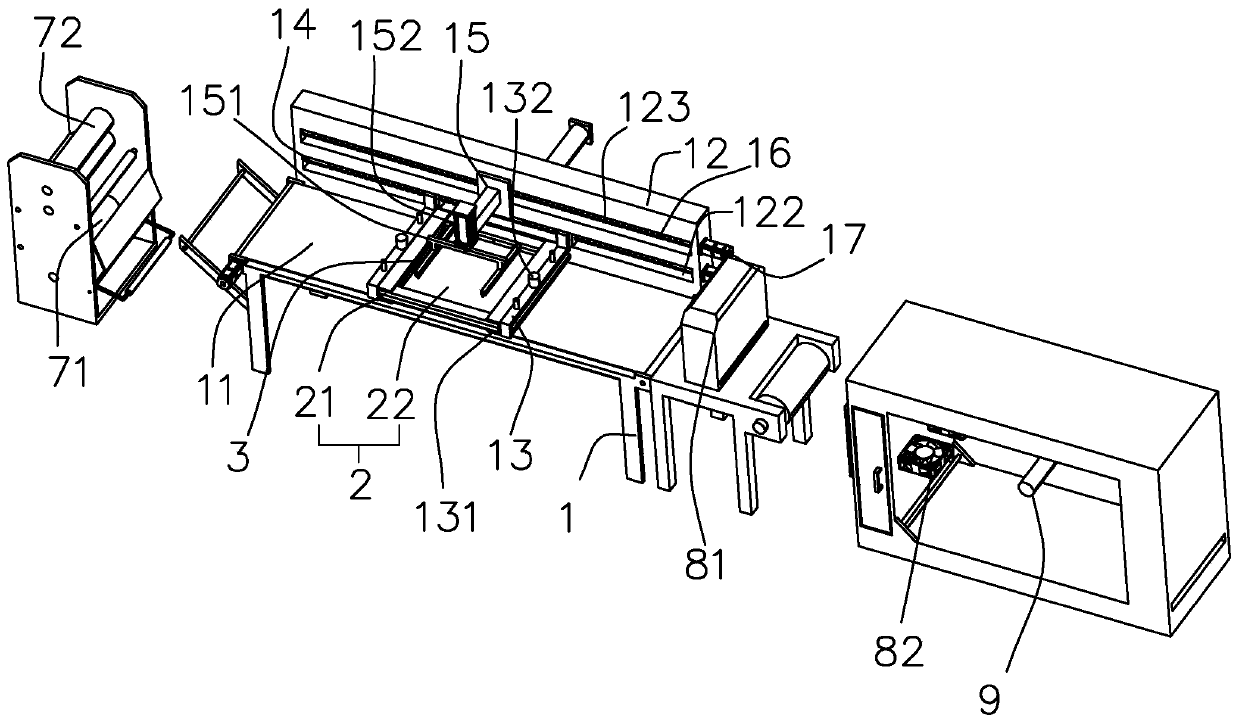

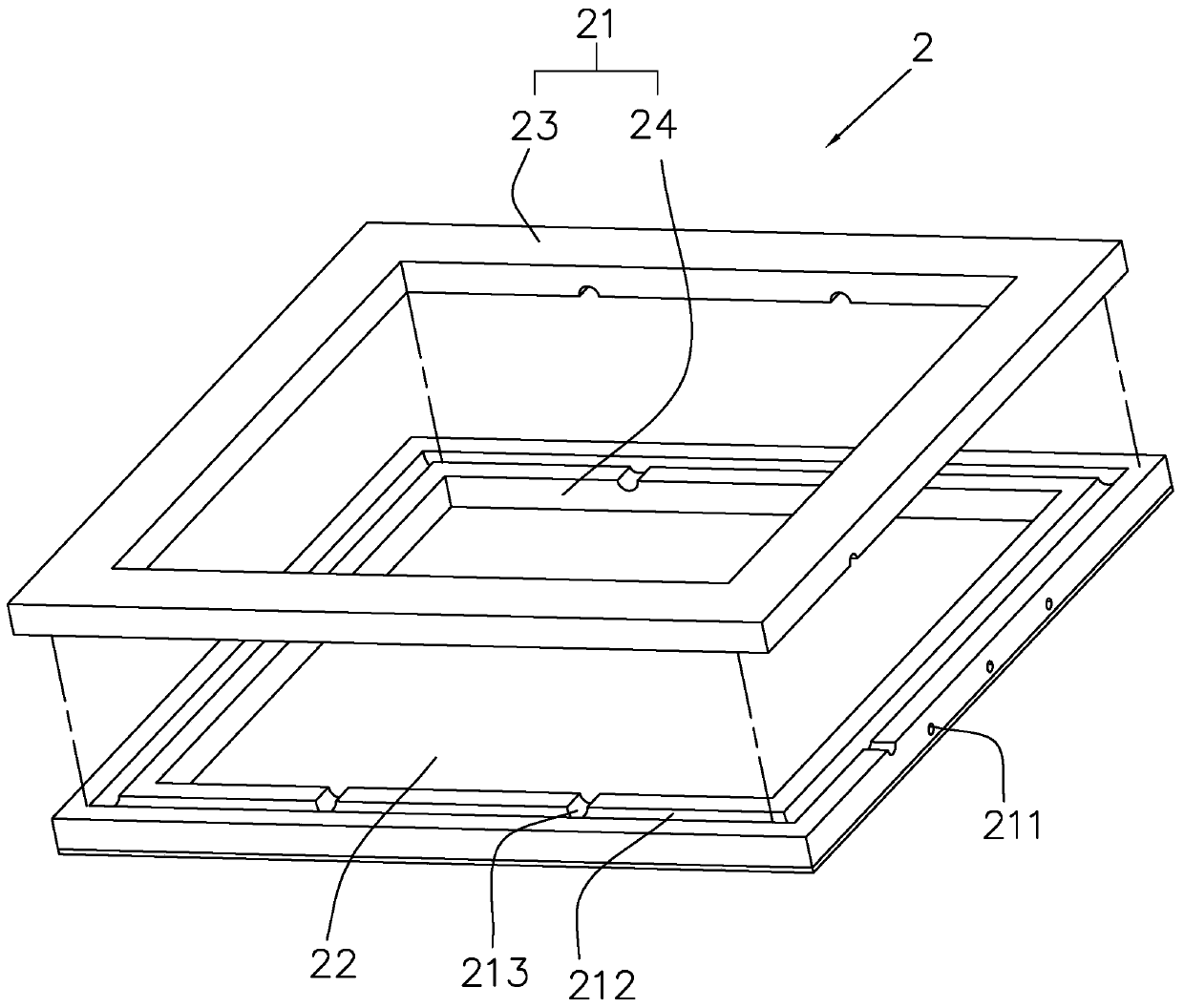

[0046] A label printing equipment such as figure 1 , including a frame 1, the frame 1 is provided with an unwinding device, a positioning device, a traveling device, a drying device and a winding device. The positioning device is connected with a silk screen 2, and the running device is connected with a scraper 3. The material tape is placed on the unwinding device, passes through the lower surface of the screen 2, the drying device and finally connects with the winding device. The unwinding device discharges the material, the screen 2 and the scraper 3 cooperate with each other to print, the drying device dries the printed matter, and finally winds up on the winding device.

[0047] Such as figure 1 , The unwinding device includes a material roller 71 and several tension rollers 72. The material belt is sleeved on the material roller 71, and the tension is adjusted through several tension rollers 72 in turn, and then passes through the positioning device.

[0048] Such as ...

Embodiment 2

[0070] A label printing process, including a label printing device in Embodiment 1,

[0071] S1, set the material belt on the material roller 71, and tension it through the tension roller 72;

[0072] S2, the material tape is laid on the workbench 11, located directly below the screen 2;

[0073] S3, the material tape passes through the drying device and is wound on the winding roller 9;

[0074] S4, the operator clamps and fixes the screen 2 through the positioning bar 13;

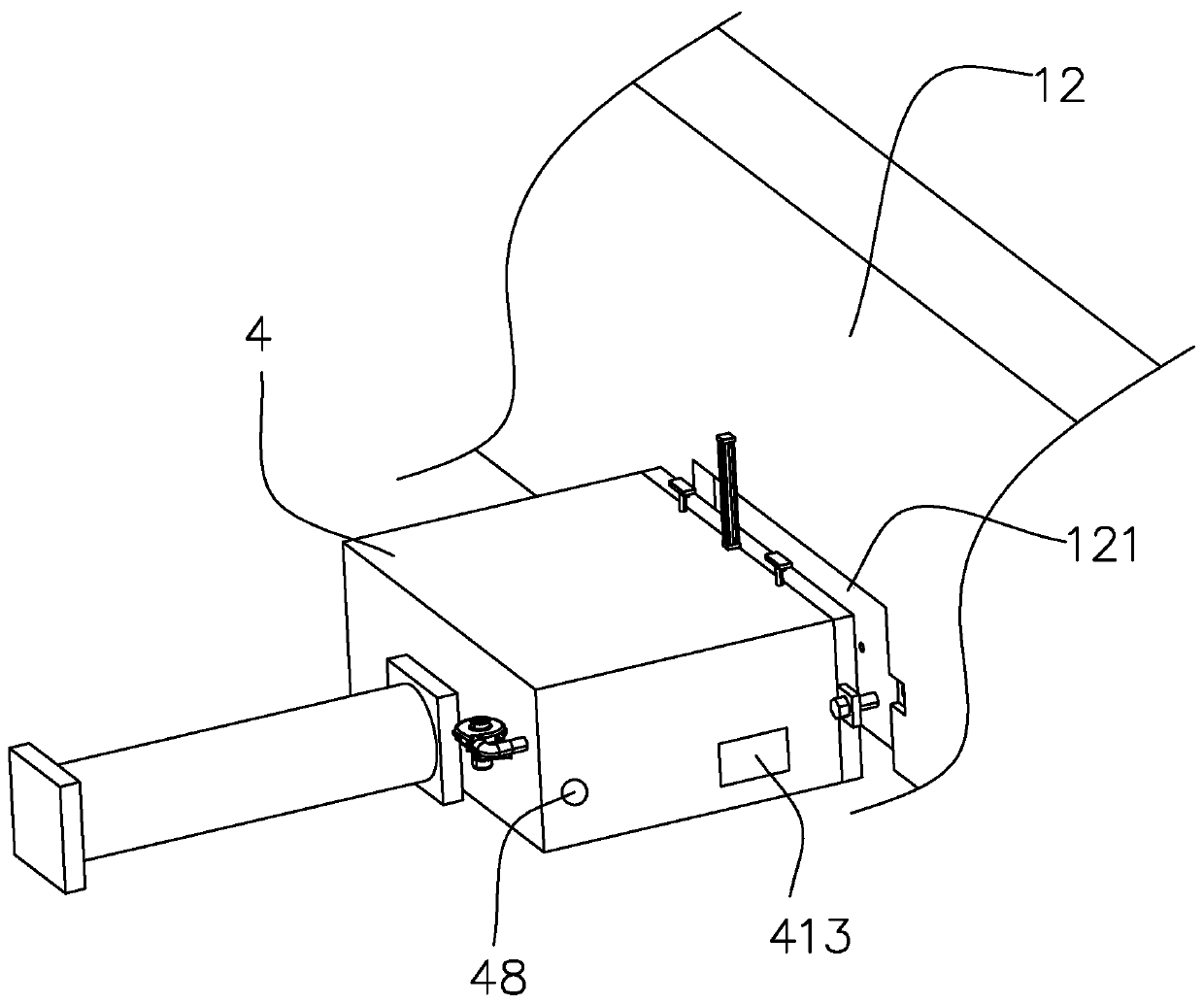

[0075] S5, the operator adds ink to the ink filling chamber 41 through the ink filling port 413;

[0076] S6. The operator presses the ink refill button 48, and the ink is sprayed from the ink refill cartridge 4 into the screen 2;

[0077] S7, the travel motor 17 starts, the scraper 3 scrapes the screen 22, and the ink is printed on the material belt;

[0078] S8. After the tape is printed, it is dried and cooled by the uv drying box 81 and the blower 82 , and finally winds up on the winding roller 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com