Automatic electric power material sample sealing system

An electric power material and automatic technology, applied in electromagnetic radiation induction, instruments, induction record carriers, etc., can solve the problems of rising error rate, wrong blind sample labeling, low confidentiality, etc., to prevent collusion attacks, ensure detection results, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, which should not be construed as limiting the present invention.

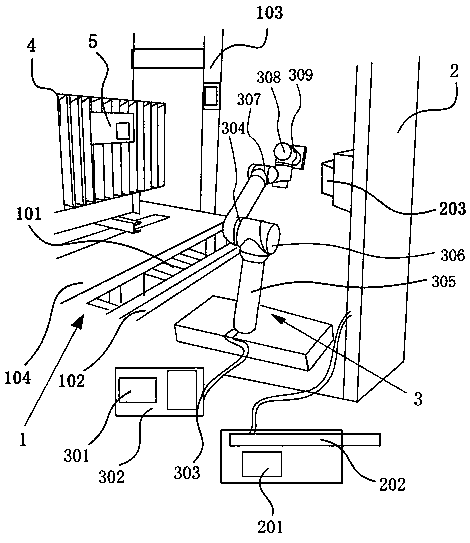

[0019] as attached figure 1 As shown, an automatic sample sealing system for electric power materials includes an automatic cabinet transport device 1, a label identification system 2 and a multi-axis machine grabbing device 3; wherein

[0020] The cabinet automatic transport equipment 1 is equipped with power samples to be sealed. The cabinet automatic transport equipment 1 is composed of a chain conveyor 101, a roller conveyor 102, a jacking transplanter 103 and a tray 104. The cabinet automatic transport equipment 1 The end-to-end connection forms a continuous conveying line, an instruction is issued, and the tray 104 enters the conveying line system and reaches the inspection and acceptance entrance of the inspection center;

[0021] The label recognition system 2 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com