Assembling device suitable for C type retaining ring

An assembly device and C-shaped clasp technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inconvenient operation and low assembly efficiency of C-shaped clasps, and achieve convenient operation, labor saving, and reliable assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

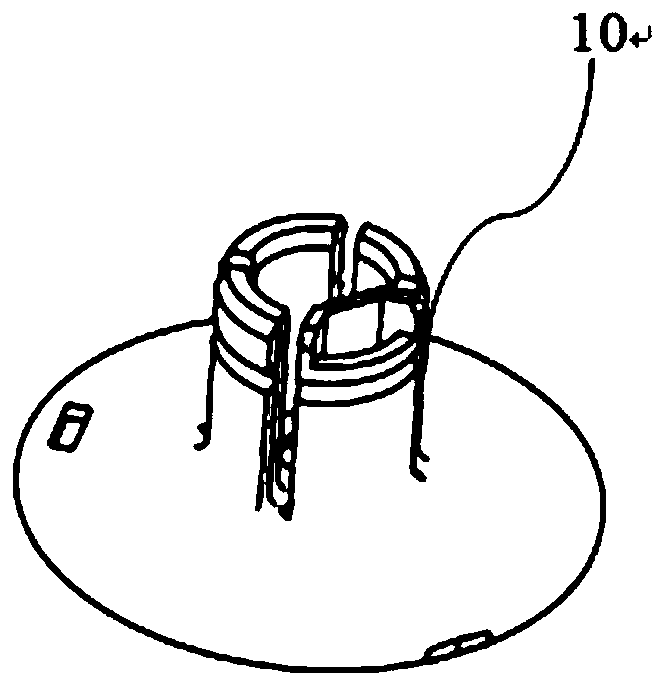

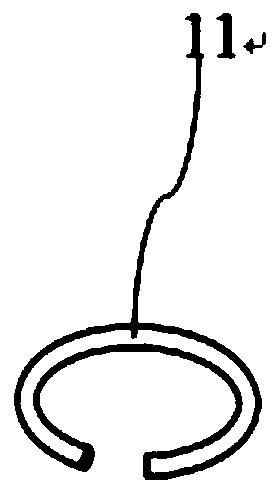

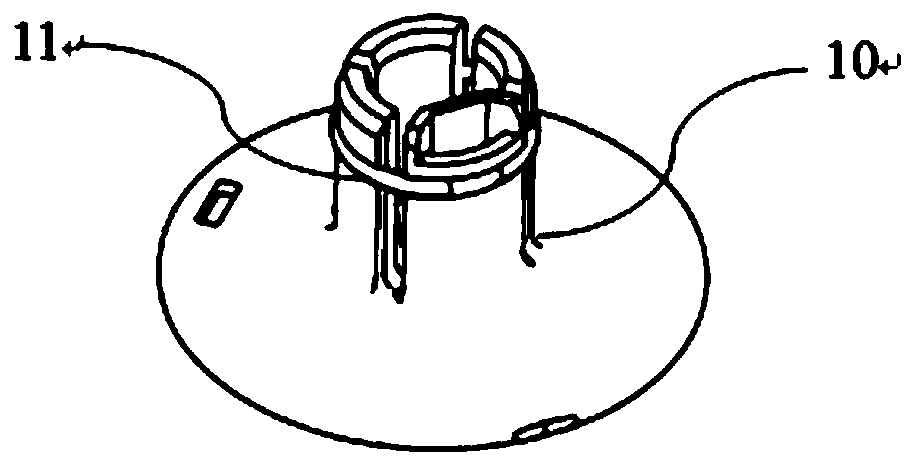

[0029] Such as Figure 1 to Figure 6 As shown, the assembly device suitable for C-shaped clasps includes a base plate 1, a clasp installation module mechanism 2 vertically arranged on the base plate 1, and a clasp installation module mechanism 2 horizontally arranged on the base plate 1 and corresponding to the clasp installation module mechanism 2. Product carrier module mechanism3. The bottom plate 1 is the supporting structure of the whole device, and supporting columns are arranged at its four peripheral corners to provide stable and reliable support. The structure of product 10 is as follows figure 1 Shown, the structure of C-type clasp 11 is as follows figure 2 As shown, wherein the product has a plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com