A paper shredder combination cutter integrated with vertical and horizontal cutting

A combination of cutter and paper shredder technology, applied in the direction of grain processing, etc., can solve the problems of incomplete crushing and poor crushing effect, and achieve the effect of smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

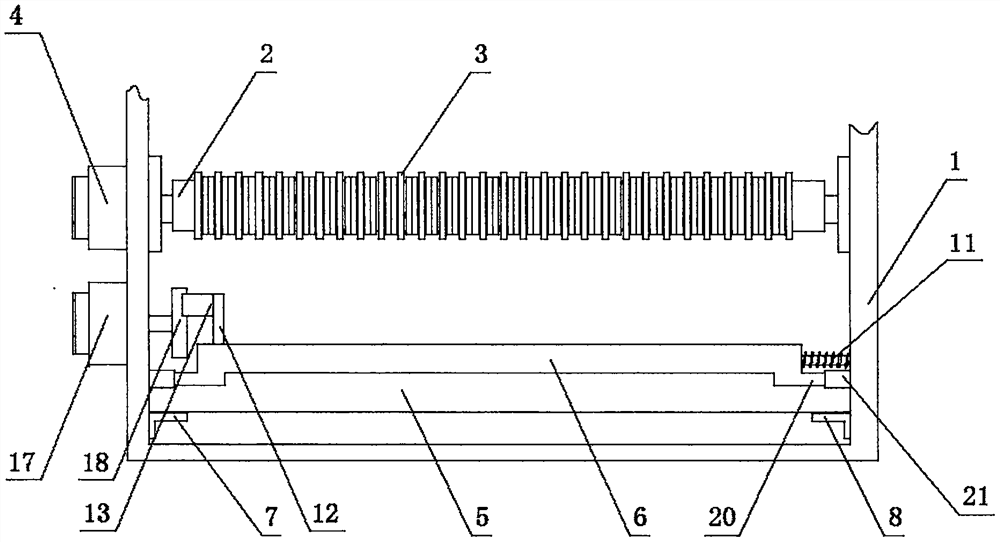

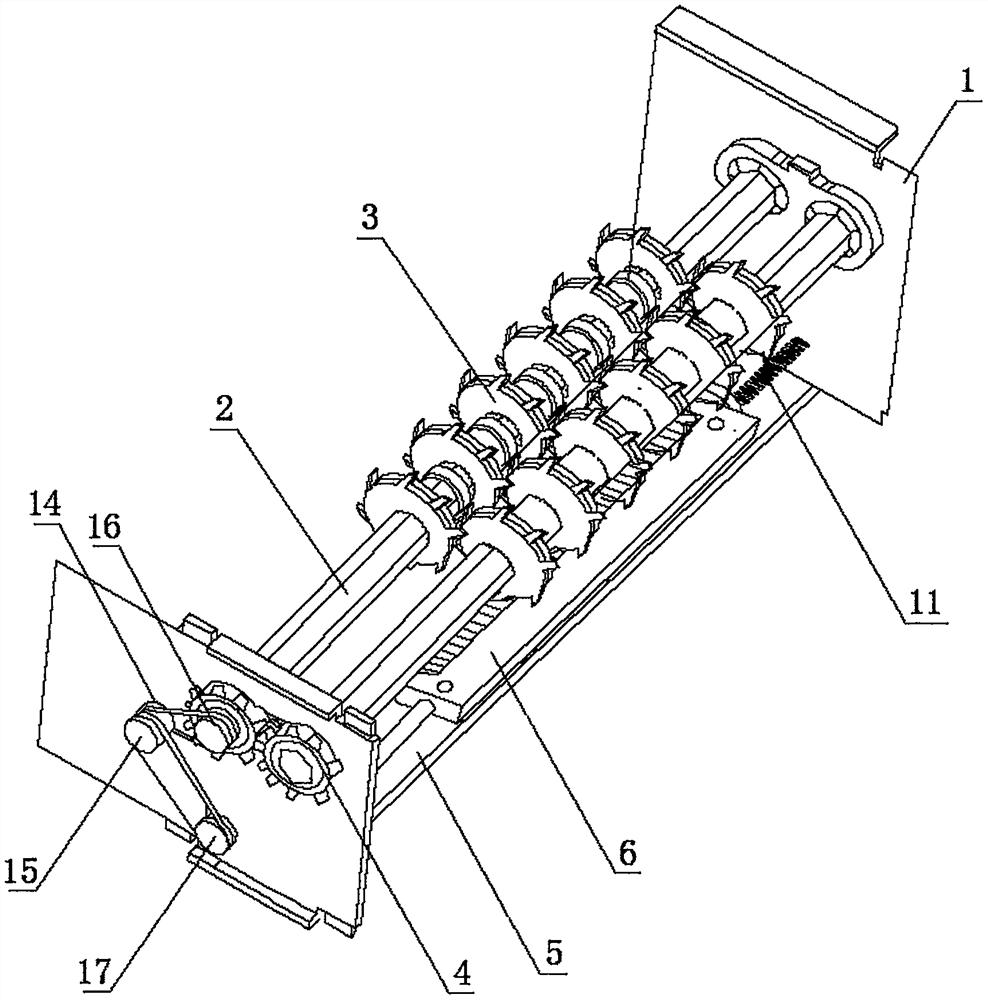

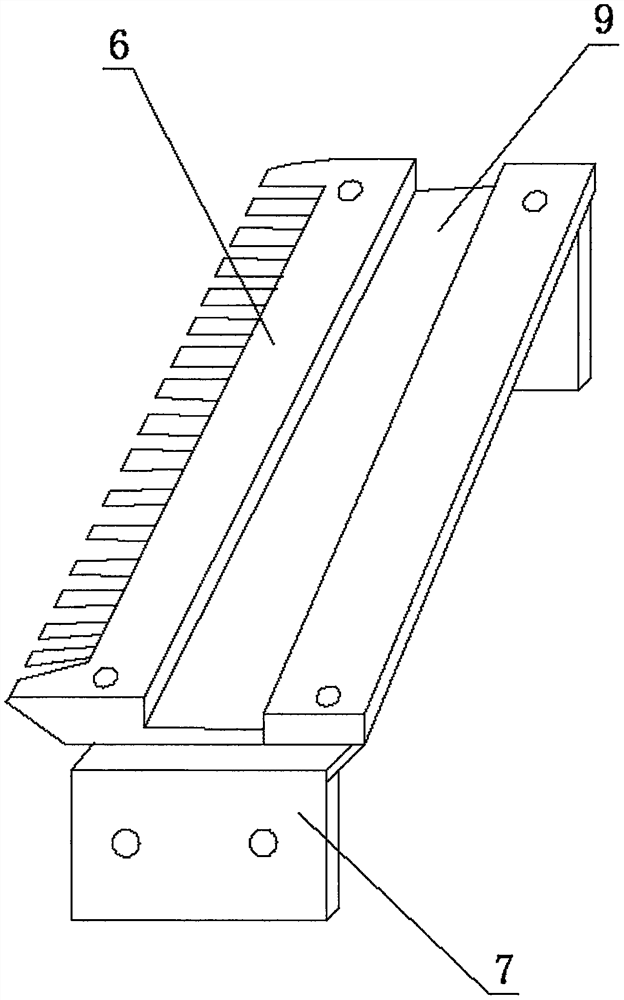

[0035] see Figure 1-5 , the present invention provides the following technical solutions:

[0036] A paper shredder combination cutter integrating vertical and horizontal cutting, including:

[0037] A frame composed of two left and right fixed mounts 1 arranged vertically and parallel to each other;

[0038] Two cutter shafts 2 are arranged side by side between the left and right fixed frames 1 and are parallel to each other. The two ends of the cutter shaft 2 are installed on the fixed frame 1 through bearings respectively. Longitudinal blades 3 are arranged at intervals. The longitudinal blades 3 are disc-shaped. The edges of the longitudinal blades 3 are evenly provided with a plurality of cutting teeth. Mate connection. A plurality of longitudinal blades 3 are fixedly mounted on the cutter shaft 2 at certain intervals through spacers, and the plurality of longitudinal blades 3 can be designed to intersect each other.

[0039] One end of the left side of the two cutte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com