Oriented draining dressing with effect of keeping wound moderate wetting and preparation method thereof

A directional and moisturizing technology, applied in dressings, viscous dressings, medical science and other directions, can solve the problems of limited bacteriostatic effect and difficulty in maintaining moderately moist wounds, and achieve excellent antibacterial effect, low cost and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

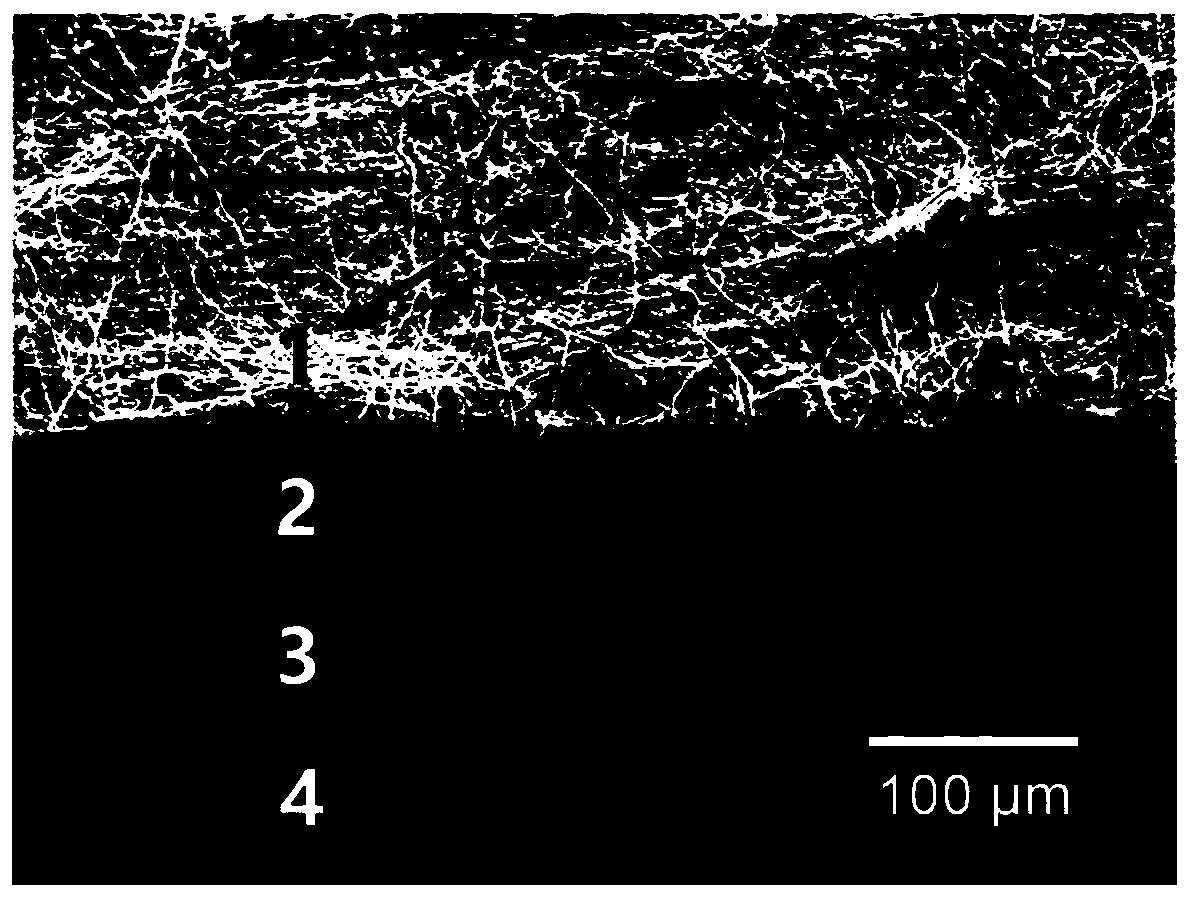

Image

Examples

Embodiment 1

[0037] A preparation method for a directional fluid-conducting dressing that maintains a moderately moist wound, the steps of which mainly include:

[0038] (1) With one side surface of the chitosan nonwoven fabric with a thickness of 50 μm as the receiving surface, the pectin solution with a concentration of 5wt% is carried out by electrospinning to form a pectin nanofiber film with a thickness of 50 μm, and the voltage of the electrospinning is 10kV, the receiving distance is 10cm, and the perfusion rate of spinning solution is 0.2mL / h;

[0039] (2) Immerse the composite film formed by chitosan nonwoven fabric and pectin nanofiber film into saturated calcium chloride ethanol solution to carry out crosslinking reaction, the temperature of crosslinking reaction is normal temperature, and the time is 10min;

[0040] (3) The dispersion liquid I of bacterial cellulose is coated on the surface of the pectin nanofiber membrane by dip coating process to form a bacterial cellulose ul...

Embodiment 2

[0054] A preparation method for a directional fluid-conducting dressing that maintains a moderately moist wound, the steps of which mainly include:

[0055] (1) With one side surface of the chitosan nonwoven fabric with a thickness of 60 μm as the receiving surface, the dialdehyde pectin solution with a concentration of 10 wt% is electrospun to form a dialdehyde pectin nanofiber film with a thickness of 60 μm, and the electrospinning The voltage of the silk is 20kV, the receiving distance is 20cm, and the perfusion speed of the spinning solution is 2mL / h;

[0056] (2) the composite film that chitosan nonwoven fabric and dialdehyde pectin nanofiber film forms is immersed in the adipic acid dihydrazide ethanol solution of concentration 1wt% and carries out cross-linking reaction, and the temperature of cross-linking reaction is normal temperature, and the time is 20min;

[0057] (3) The dispersion liquid I of bacterial cellulose is coated on the surface of the dialdehyde pectin...

Embodiment 3

[0062] A preparation method for a directional fluid-conducting dressing that maintains a moderately moist wound, the steps of which mainly include:

[0063] (1) take one side surface of the chitosan nonwoven fabric of thickness 100 μ m as receiving surface, the konjac glucomannan solution that concentration is 15wt% carries out electrospinning and forms the konjac glucomannan nanofiber membrane of thickness 80 μ m, The voltage of electrospinning is 50kV, the receiving distance is 30cm, and the perfusion speed of spinning solution is 5mL / h;

[0064] (2) The composite film that chitosan nonwoven fabric and konjac glucomannan nanofiber film forms is immersed in the adipic acid dihydrazide ethanol solution of concentration 5wt% and carries out cross-linking reaction, and the temperature of cross-linking reaction is normal temperature, time 60min;

[0065] (3) The dispersion liquid I of bacterial cellulose is coated on the surface of the konjac glucomannan nanofiber membrane by di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com