Low-nitrogen premixed combustor

A premixed combustion and mixer technology, applied in burners, burners, burner ignition devices, etc., can solve the problems of high flame temperature of burners and environmental damage of nitrogen oxides, so as to reduce the production of nitrogen oxides. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

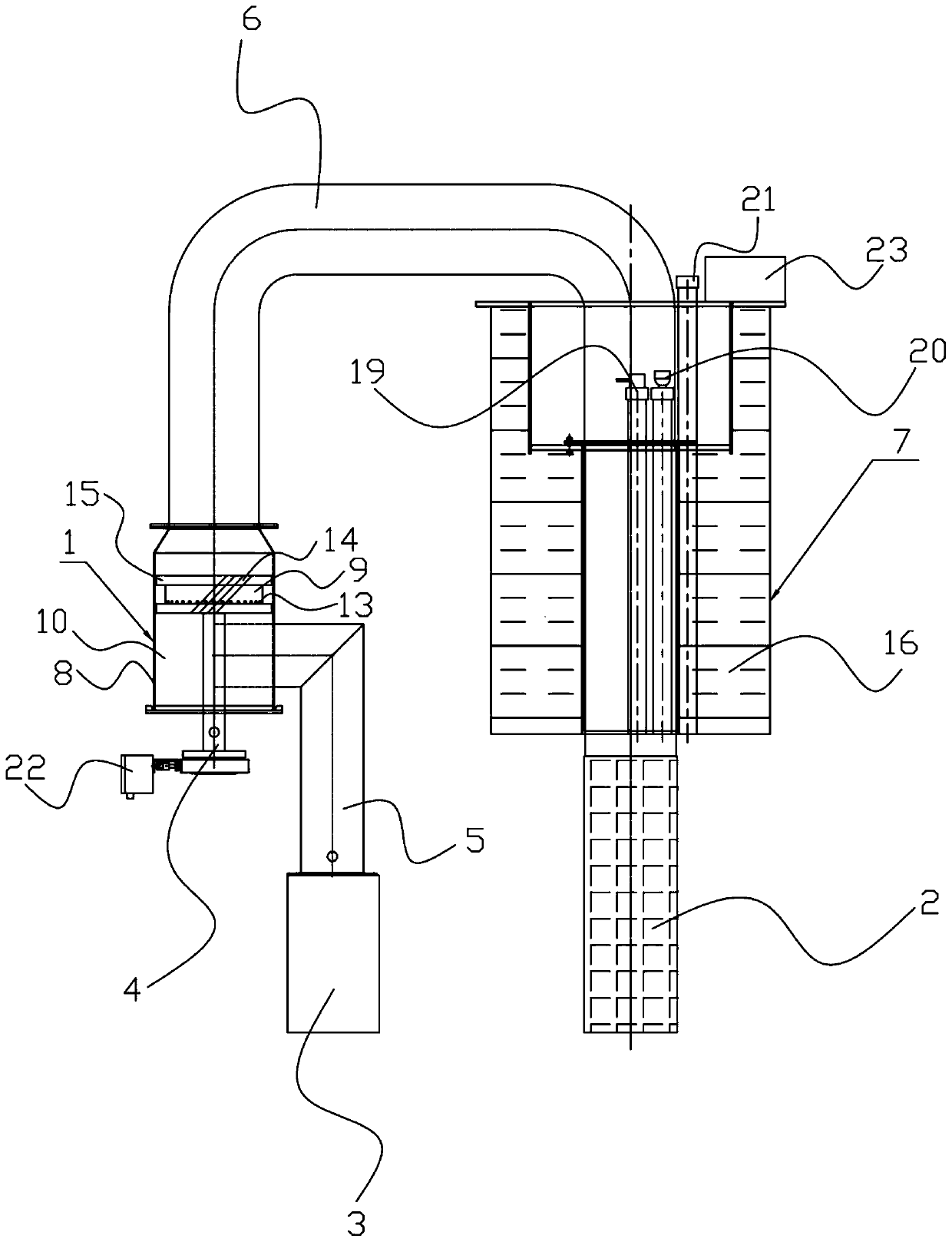

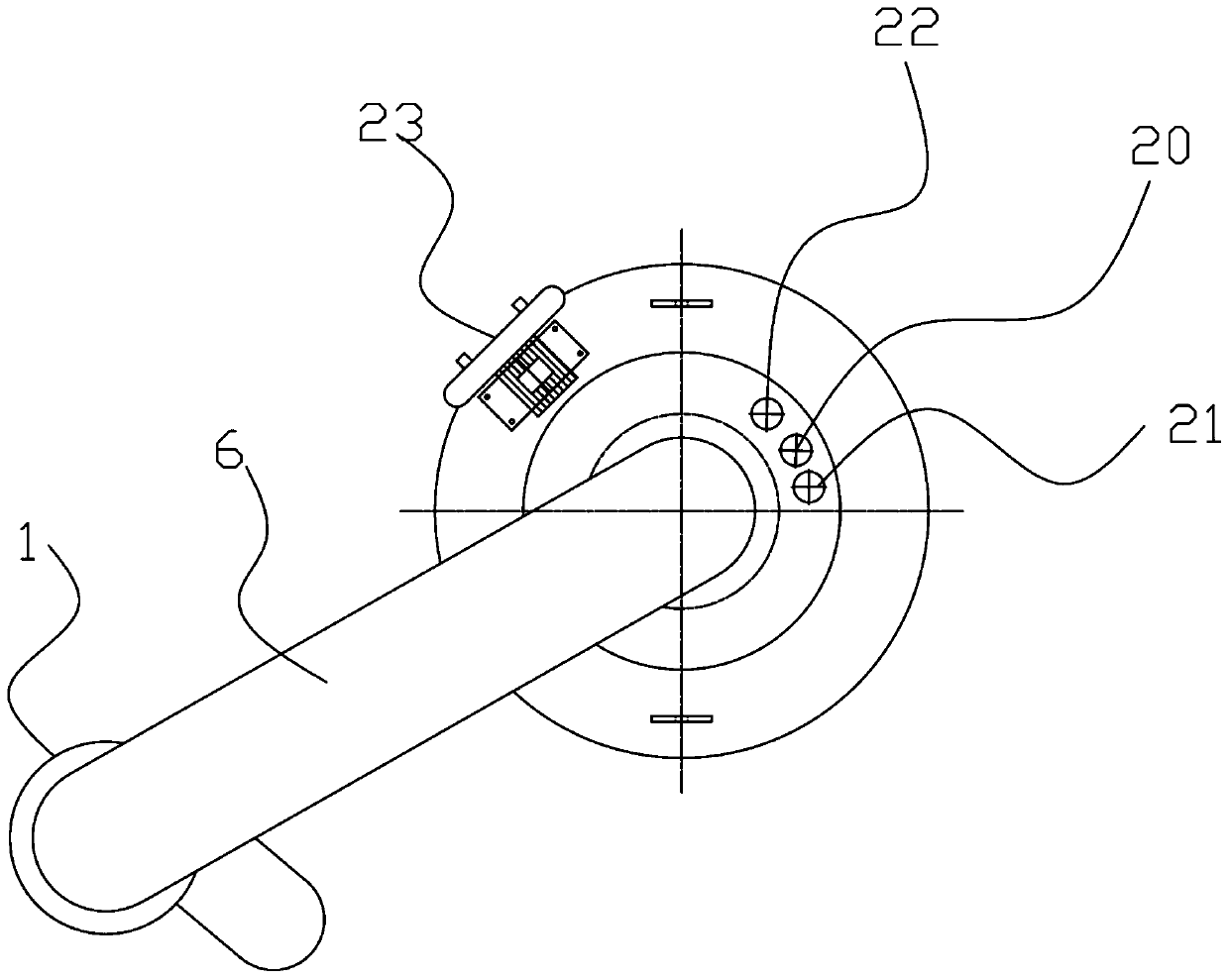

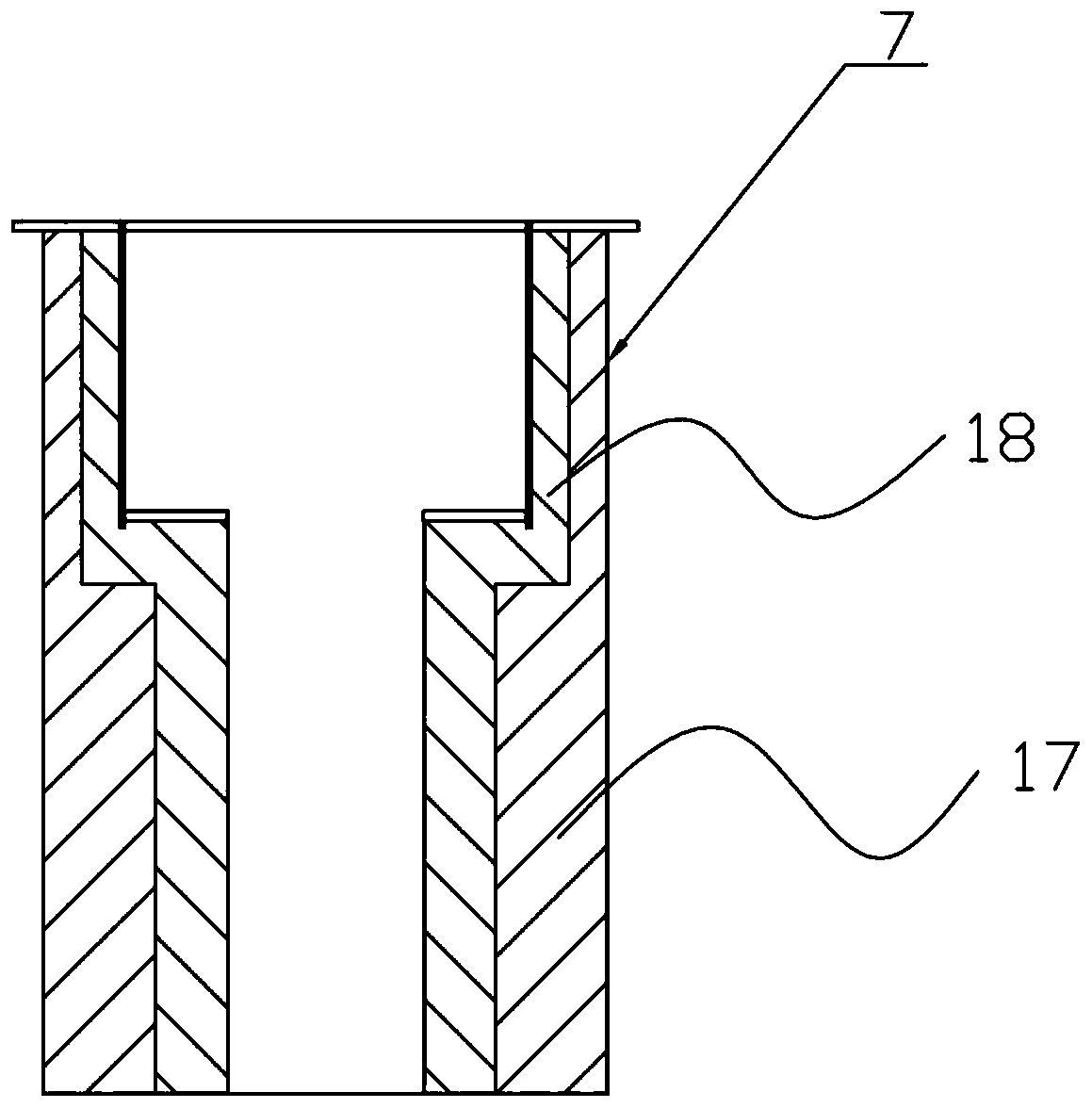

[0032] Such as Figure 1-4 As shown, a low-nitrogen premixed burner includes a mixer 1, a main combustion head 2 and a blower 3. One end of the mixer 1 is connected to a gas inlet pipe 4, and one side of the mixer 1 is fed by air. The air pipe 5 is connected to the blower 3; the other end of the mixer 1 is connected to a mixed gas delivery pipe 6, and the other end of the mixed gas delivery pipe 6 is connected to a burner body 7, and the other end of the burner body 7 Connected with the main combustion head 2;

[0033] The mixer 1 includes a housing 8, a gas outlet cylinder 9 and a mixing chamber 10, the gas outlet cylinder 9 is in the shape of a cylinder, the gas outlet cylinder 9 is provided with a gas baffle 11, and the gas inlet of the gas outlet cylinder 9 The end is connected with the gas inlet pipe 4, and a gas storage chamber 12 is formed between the gas baffle 11 and the gas inlet end of the gas outlet tube 9, and a number of gas infiltration chambers are uniformly a...

Embodiment 2

[0036] Such as figure 1 and figure 2 As shown, this embodiment is based on Embodiment 1, and a plurality of fan blades 14 are obliquely provided on the outer wall of the gas outlet cylinder 9 , and the fan blades 14 are arranged between two adjacent gas permeation holes 13 .

[0037] Several fan blades 14 are arranged obliquely on the outer wall of the gas outlet cylinder 9, and the fan blades 14 are arranged between two adjacent gas permeation holes 13, and the gas coming out of the gas permeation holes 13 is more uniformly guided by the fan blades 14. Mixed with the air entering the mixing chamber 10.

Embodiment 3

[0039] Such as figure 1 and figure 2 As shown, this embodiment is based on Embodiment 2, and the top and bottom of the fan blade 14 are provided with fixed rings 15 . The purpose of setting the fixed ring 15 on the top of the fan blade 14 is to prevent the fan blade 14 from falling off during use, which will affect the mixing accuracy during mixing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com