Double-layer rubber spring and air spring using double-layer rubber spring

A rubber spring, double-layer technology, applied in the direction of spring, spring/shock absorber, shock absorber-spring combination, etc., can solve the problem of difficult to meet the mechanical properties and fire resistance of conical rubber springs at the same time, and the installation, maintenance and disassembly of air springs. It is a big problem, and the fire resistance of the air spring has not been solved, so as to improve the reliability and service life, reduce the stress and reduce the weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A double-layer rubber spring is divided into an upper structure and a lower structure,

[0039] The upper structure is a load-bearing rubber pile composed of an upper jacket 101, an upper partition 102, an upper mandrel 103, and an upper rubber 104.

[0040] The lower structure is a fireproof rubber pile composed of the lower jacket 201, the lower partition 202, the lower mandrel 203, and the lower rubber 104.

[0041] The upper end of the lower dividing plate 202 is a limit ring, and the size of the accommodating space of the limit ring is equal to the size of the lower end of the upper dividing plate 102, and the lower end of the upper dividing plate 102 can be placed on the limit ring of the lower dividing plate 202 to prevent The upper layer separator 102 and the lower layer separator 202 are misaligned.

[0042] The outside of the lower coat 201 is a ring of bosses, and the outside of the upper coat 101 is a circle of grooves, the groove of the upper coat 101 can ...

Embodiment 2

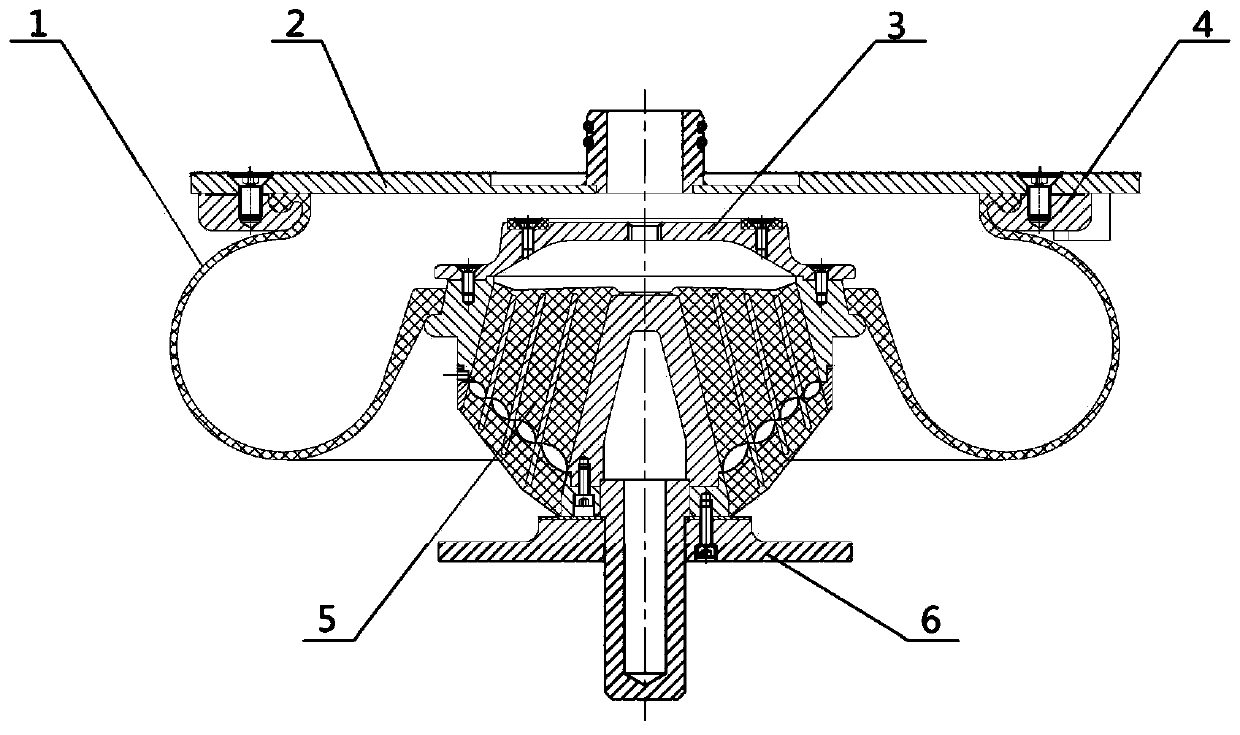

[0050] An air spring using a double-layer rubber spring, including an airbag 1, an upper cover 2, a support seat 3, a buckle 4, a double-layer rubber spring 5, and a base 6, the airbag 1 is fixed on the upper cover 2 through the buckle 4, The airbag 1 is connected to the upper coat 101 of the double-layer rubber spring, the support base 3 is fixed to the upper coat 101 of the double-layer rubber spring by bolts, and the base 6 is fixed to the lower mandrel 203 of the double-layer rubber spring by bolts , the upper cover 2 can be made of a metal plate or a rubber-coated metal. The air spring using this double-layer rubber spring can not only meet the auxiliary load-bearing function of the rubber spring when the airbag 1 is full of gas, but also can When the airbag 1 loses air, it carries out emergency force bearing, and can also meet the requirements of fire prevention while bearing the force.

[0051] When empty:

[0052] Before the double-layer rubber spring bears the force,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com