Multistage screw rod and lifting oil cylinder combined lifting device used for lifting

The technology of a screw rod and an oil cylinder is applied in the field of a combined lifting device of a multi-stage screw rod and a lifting cylinder, which can solve problems such as poor safety, and achieve the effect of solving the problem of poor safety and ensuring safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further described in conjunction with the following examples.

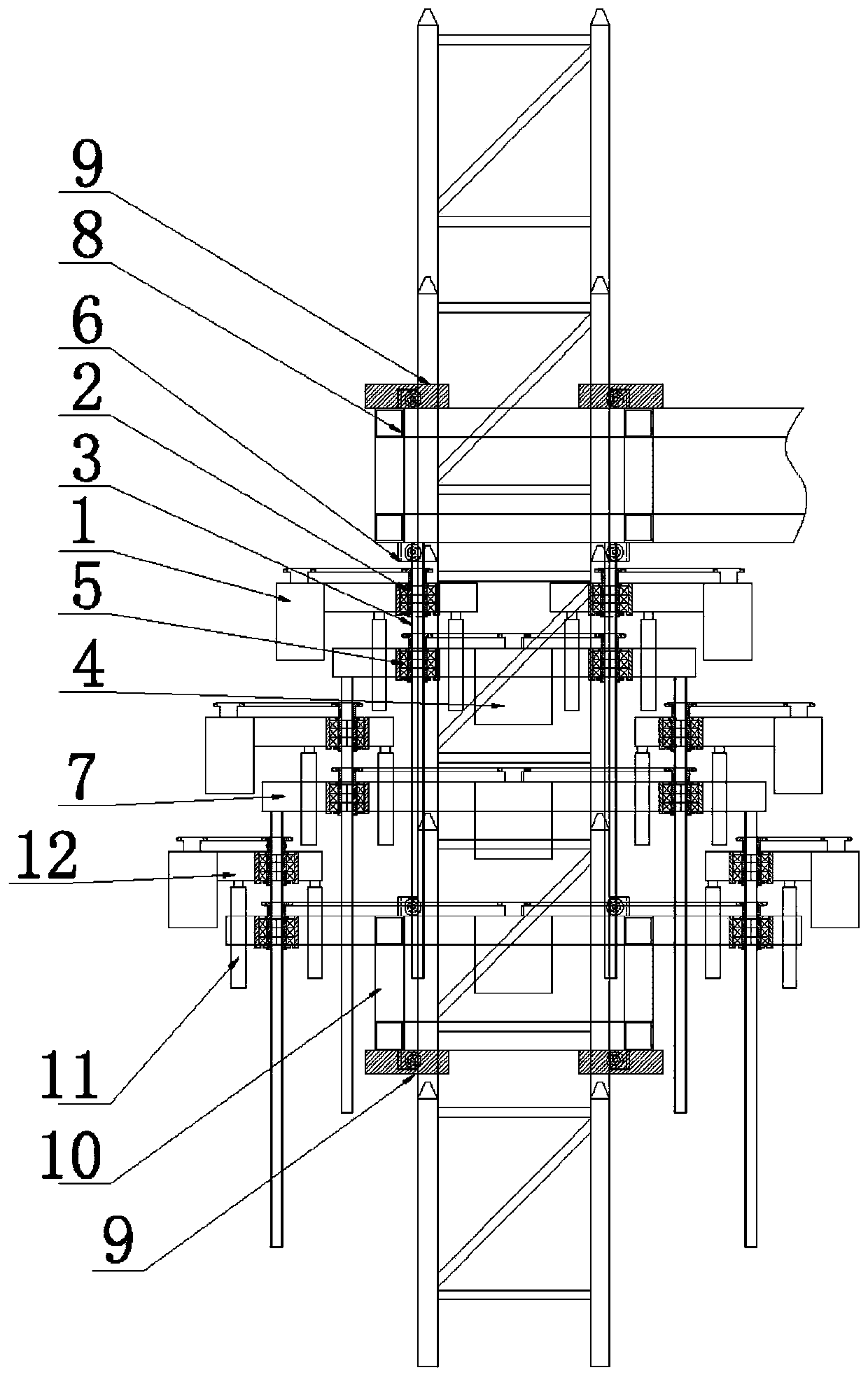

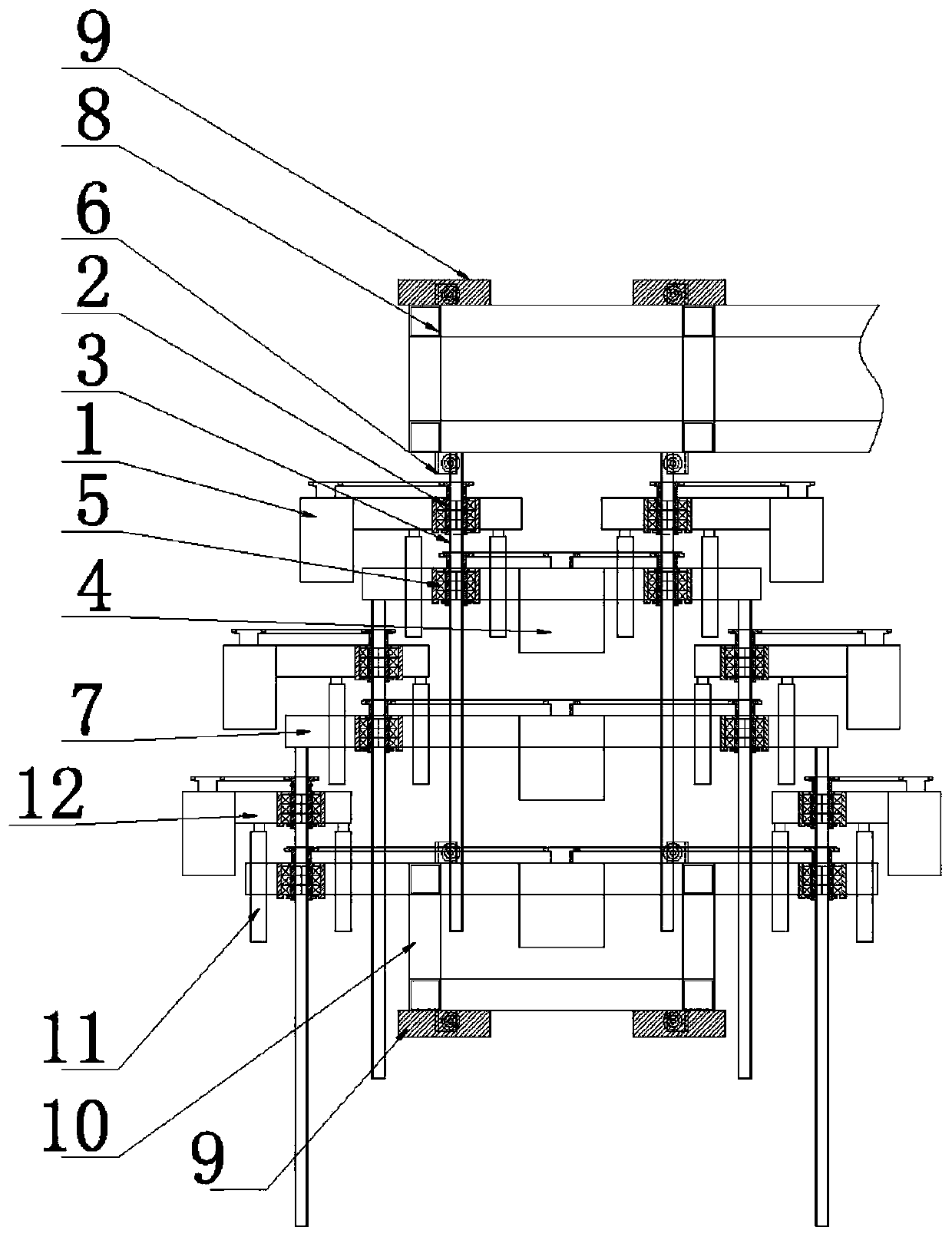

[0018] The specific embodiment of the multi-stage screw rod 3 for lifting and the lifting cylinder 11 combination lifting device of the present invention, such as figure 1 and figure 2 As shown, it includes a pressure-bearing platform 8, three movable platforms and a lower supporting frame 10 that are sheathed on the guide rails from top to bottom. The guide rail is assembled from a plurality of stacked and fixed standard sections, and each standard section is provided with a draw-in slot for the working end of the telescopic corbel 9 to be inserted into. Both the pressure-bearing platform 8 and the lower support frame 10 are provided with telescopic corbels 9, and as a preferred solution, the lower support frame 10 is provided with two telescopic corbels 9, and the two telescopic corbels 9 are symmetrically installed on the bottom of the lower support frame 10 respectively. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com