Die head temperature control system of granulator

A temperature control system and temperature control technology, applied in the field of pelletizers, can solve the problems affecting the extrusion speed of materials, different distances, slow reaction speeds, etc., to ensure the uniformity of pelletizing, precise and convenient regulation, and solve the problem of temperature rise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

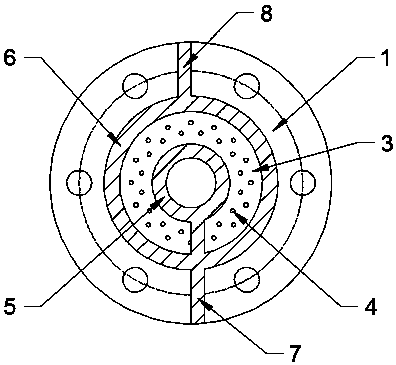

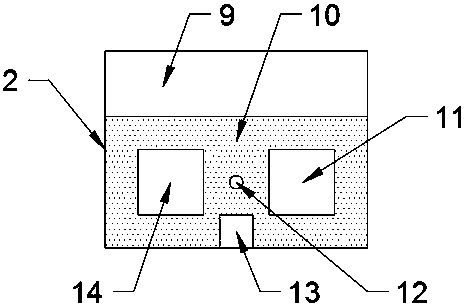

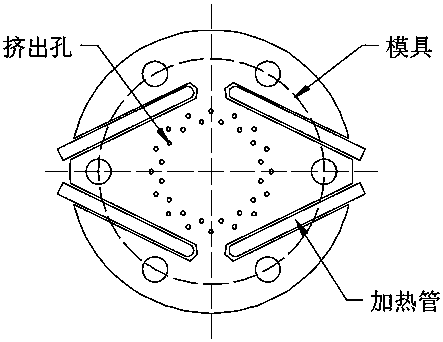

[0023] Such as figure 1 , 2 The die head temperature control system of the pelletizer shown includes a die head 1 and a die temperature controller 2 for temperature control. The die head 1 is provided with a ring-shaped extrusion orifice 3, and the extrusion orifice 3 is provided with a There are several extrusion holes 4, and the extrusion hole belt 3 formed by the extrusion hole 4 is distributed on the die head 1 in a circular shape; the inside of the extrusion hole belt 3 is provided with a first annular cavity 5, and the extrusion hole belt 3 There is a second annular cavity 6 on the outside, the first annular cavity 5 is connected to the second annular cavity 6, and the second annular cavity 6 is provided with a liquid inlet 7 and a liquid outlet 8, and the liquid flows from the liquid inlet 7 enters the first annular cavity 5 and the second annular cavity 6, and since the distance from the two annular cavities to the extrusion hole 4 is the same, the adjustment of the ...

Embodiment 2

[0029] This embodiment is further optimized on the basis of Embodiment 1. A touch display screen electrically connected to the control module 9 is installed on the control module 9, and the temperature can be visualized and adjusted through the touch display screen, which is convenient for production according to production requirements. For precise control.

[0030] A flow meter and a pressure gauge are installed on the pipeline to realize the observation and regulation of the flow rate of the circulating fluid, so as to facilitate better control of the temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com