Steering slip method of heavy rolling mill archway in confined space

A rolling mill archway and limited space technology, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of unsafe and efficient sliding operation, complex structure, etc., and achieve safety in the sliding process Reliable, simple sliding track structure and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is further illustrated below by specific examples.

[0023] Such as Figure 1~Figure 3 As shown, a steering slip method for a heavy rolling mill archway in a confined space, including

[0024] Step 1. Construction preparation;

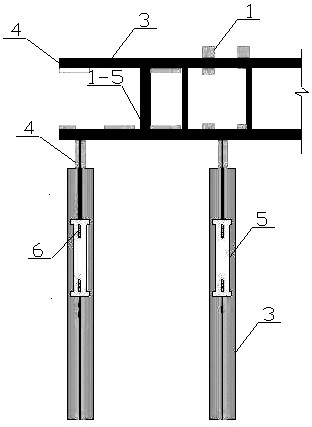

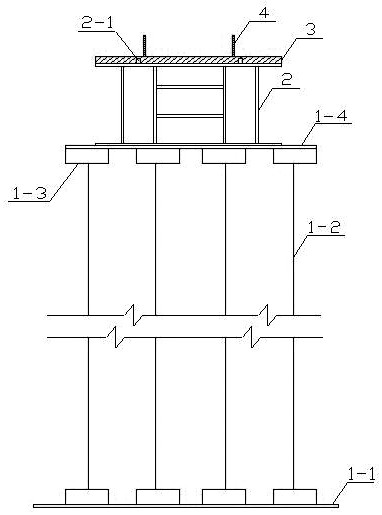

[0025] Step 2, making and installing the sliding track; installing the sliding track in the equipment foundation tunnel, including buttress 1, supporting track beam 2, track steel plate 3 and track baffle 4;

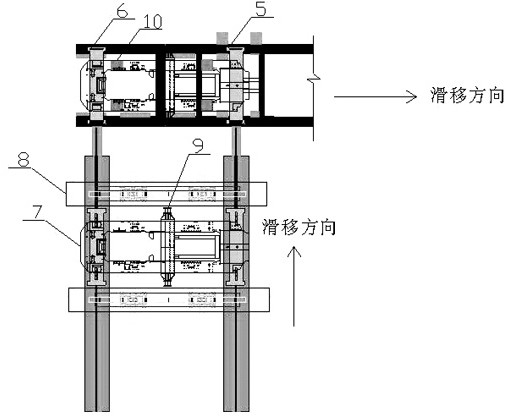

[0026] Step 3, install the sliding device; the sliding device includes a sliding beam 5 and a roller 6, and the sliding beam includes a sliding support, a sliding main beam, a transverse lifting lug, and a longitudinal lifting lug;

[0027] Step 4, the heavy rolling mill archway is unloaded and put in place; use the hydraulic gantry crane 8 to unload the heavy rolling mill archway 7, hoist it to the sliding beam 5, and install the spreader 9;

[0028] Step 5, the heavy-duty rolling mill archway slips once; hang the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com