Dynamic weighing and sorting integrated device for logistics

A dynamic weighing and sorting technology, which is applied in the field of logistics, can solve the problems of pressure sensor data deviation, weighing accuracy reduction, and easy vibration, etc., and achieve the effect of safe and convenient use, convenient use of the device, and reduced bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

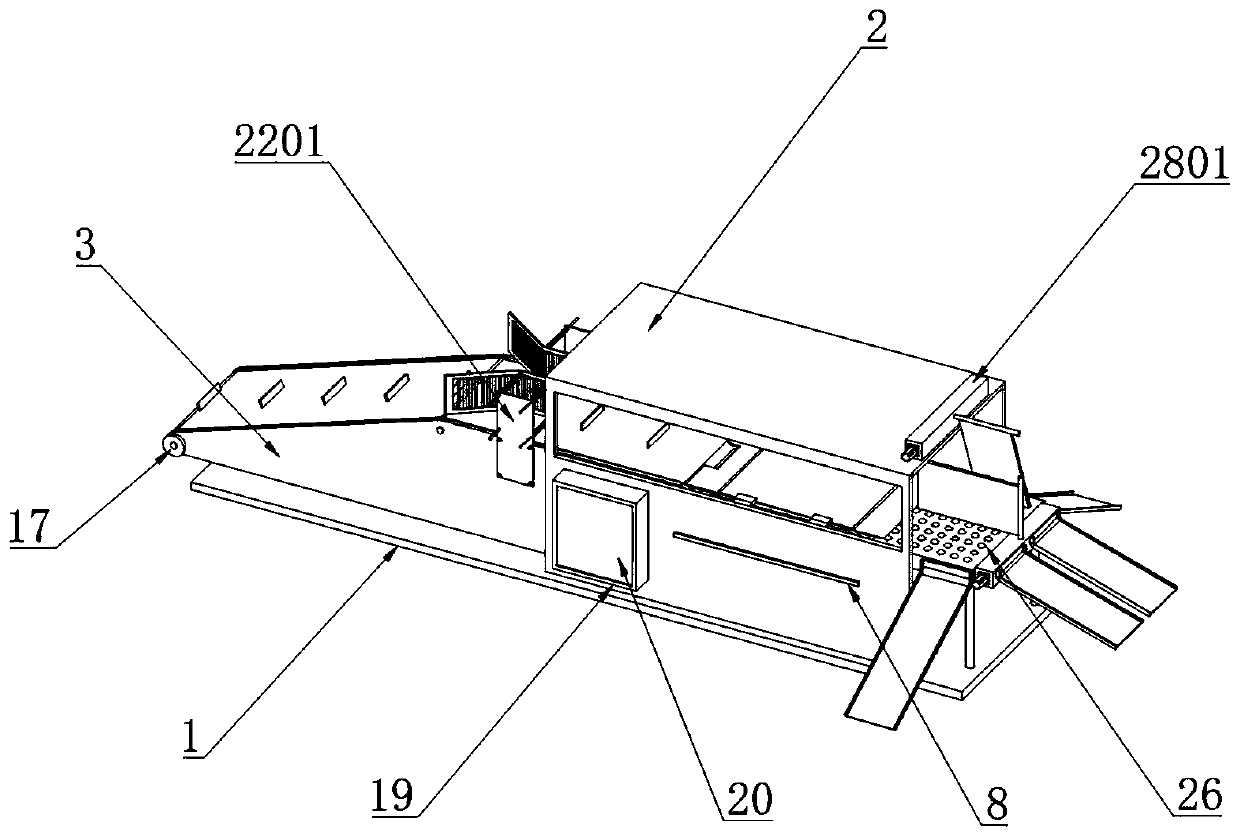

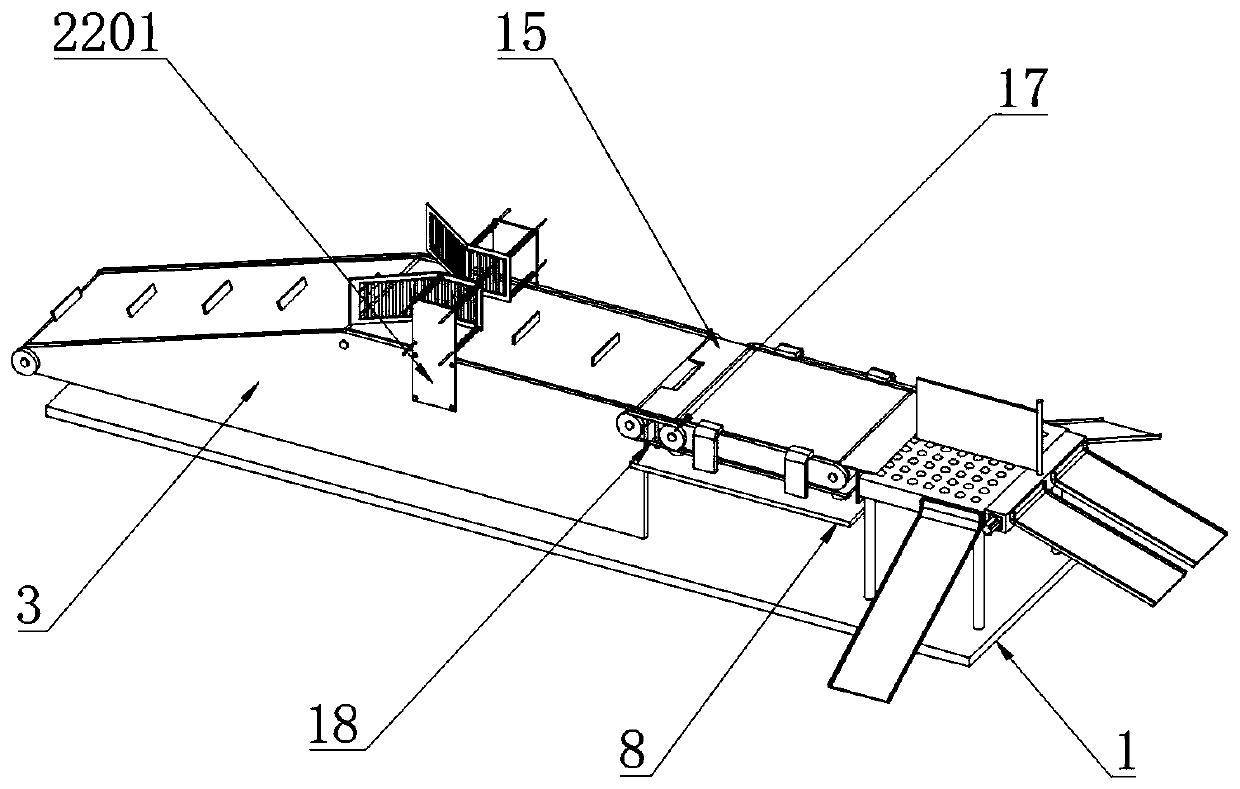

[0042] Example: such as Figure 1-9As shown, the present invention provides a technical solution, a logistics dynamic weighing and sorting integrated device, including a bottom plate 1, the top of the bottom plate 1 is symmetrically welded with a trapezoidal side plate 3, two trapezoidal side plates 3 top two corners and one side of the bottom The first fixed shaft 4 is rotatably connected between the corners, and the middle part of the first fixed shaft 4 is rotatably connected with the first set of rollers 5. The outer drive of the first set of rollers 5 is connected with the feeding conveyor belt 6. 6 Baffles 7 are equidistantly installed on the outer surface;

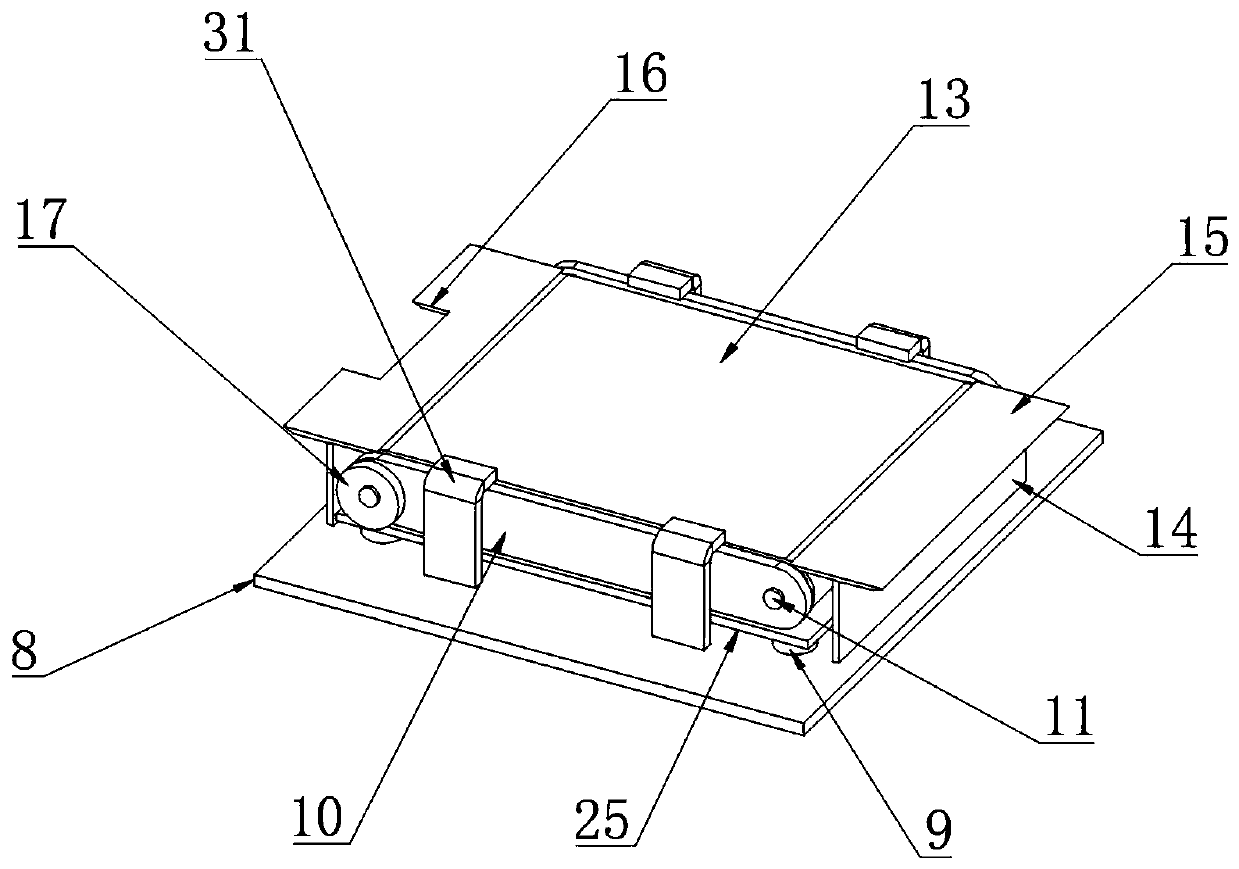

[0043] A protective shell 2 is installed at the top of the bottom plate 1 corresponding to one side of the trapezoidal side plate 3, and the middle part of the protective shell 2 is inserted with an installation board 8, and a pressure sensor 9 is installed at each corner of the top of the installation board 8, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com