Graphene-based LED epitaxial growth method

A technology of epitaxial growth and graphene, which is applied in the manufacture of semiconductor devices, electrical components, semiconductor/solid state devices, etc., can solve the problems of high chip grinding fragmentation rate, large warping of epitaxial wafers, and low product yield, so as to reduce epitaxy Effects of growth warping, improved crystal quality, and improved properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

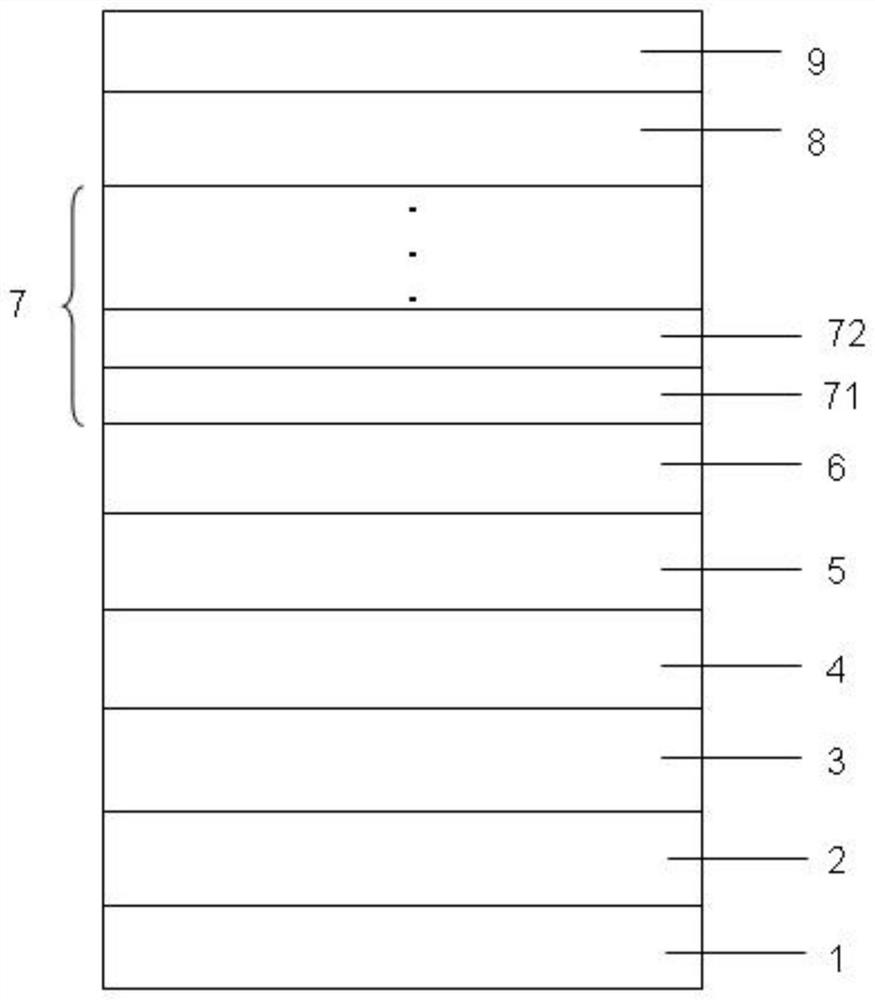

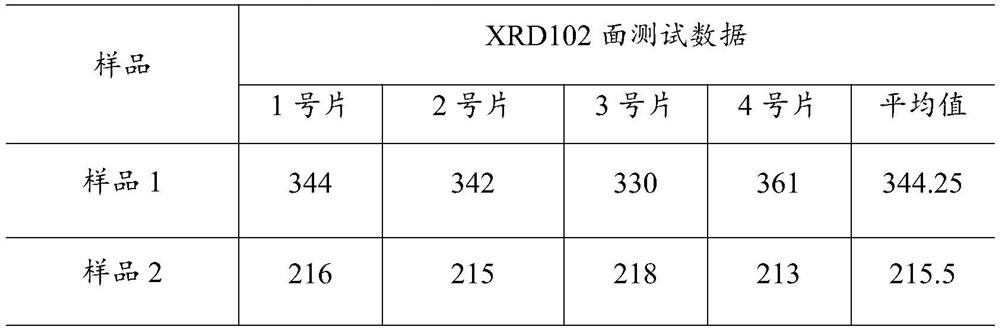

[0042] The invention uses PECVD to prepare graphene film on the sapphire substrate, and then uses MOCVD to grow high-brightness GaN-based LED epitaxial wafers. When growing high-brightness GaN-based LED epitaxial wafers, high-purity H 2 or high purity N 2 or high purity H 2 and high purity N 2 The mixed gas as the carrier gas, high-purity NH 3 As the N source, the metal-organic source trimethylgallium (TMGa), the metal-organic source triethylgallium (TEGa) is used as the gallium source, the trimethylindium (TMIn) is used as the indium source, and the N-type dopant is silane (SiH 4 ), trimethylaluminum (TMAl) as the aluminum source, and the P-type dopant as magnesium dicene (CP 2 Mg), the substrate is (0001) plane sapphire. The invention solves the problem of heterogeneous epitaxial growth of defects induced by lattice mismatch existing in the LED epitaxial growth in the prior art. The high-purity gas described in the present invention has a purity value of 99.999%, and t...

Embodiment 2

[0056] A conventional LED epitaxial growth method is provided below as a comparative example of the present invention.

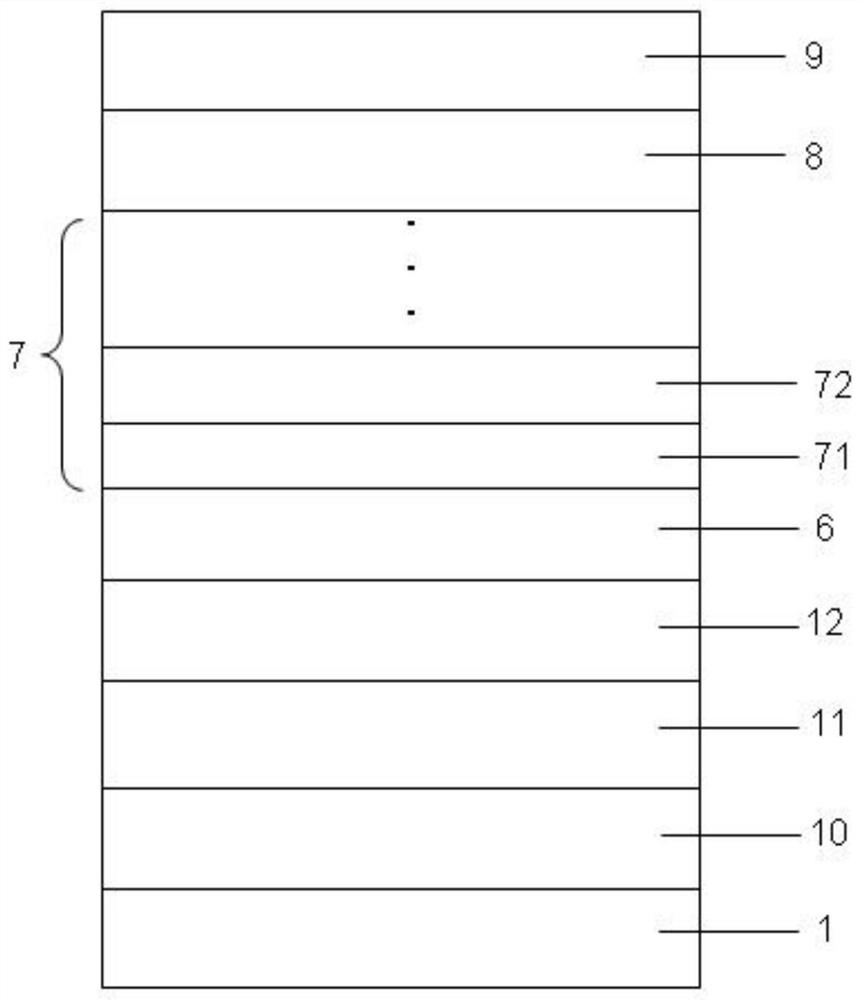

[0057] like figure 2 As shown, the conventional LED epitaxial growth method includes the following steps:

[0058] Step 1, processing sapphire substrate 1: Into the reaction chamber of the metal organic chemical vapor deposition system with the substrate placed, H at 900°C-1100°C 2 Under the atmosphere, feed 50L / min-100L / min of H 2 , keep the reaction chamber pressure at 100mbar-200mbar, and process the sapphire substrate for 5min-10min.

[0059] Step 2, grow GaN low-temperature buffer layer 10: cool down to 500°C-600°C, keep the reaction chamber pressure at 300mbar-600mbar, and feed NH with a flow rate of 40L / min-60L / min 3 , 50sccm-100sccm TMGa and 50L / min-90L / min H 2 , growing a GaN low-temperature buffer layer 10 with a thickness of 30nm-60nm on a sapphire substrate.

[0060] Step 3, grow 3D GaN layer 11: raise the temperature to 850°C-1000°C, keep ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com