Method for designing single-arc pressure surface blade profile of steam turbine

A design method and single-arc technology, applied in the field of impeller machinery, can solve problems such as increasing blade processing costs, achieve broad market application prospects and competitiveness, excellent blade processing technology and aerodynamic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A steam turbine with a drum stage blade, the specific parameters are: back pressure is 8.7bar, flow rate is 20kg / s, isentropic efficiency is 98%, total inlet pressure is 10bar, and total inlet temperature is 633K.

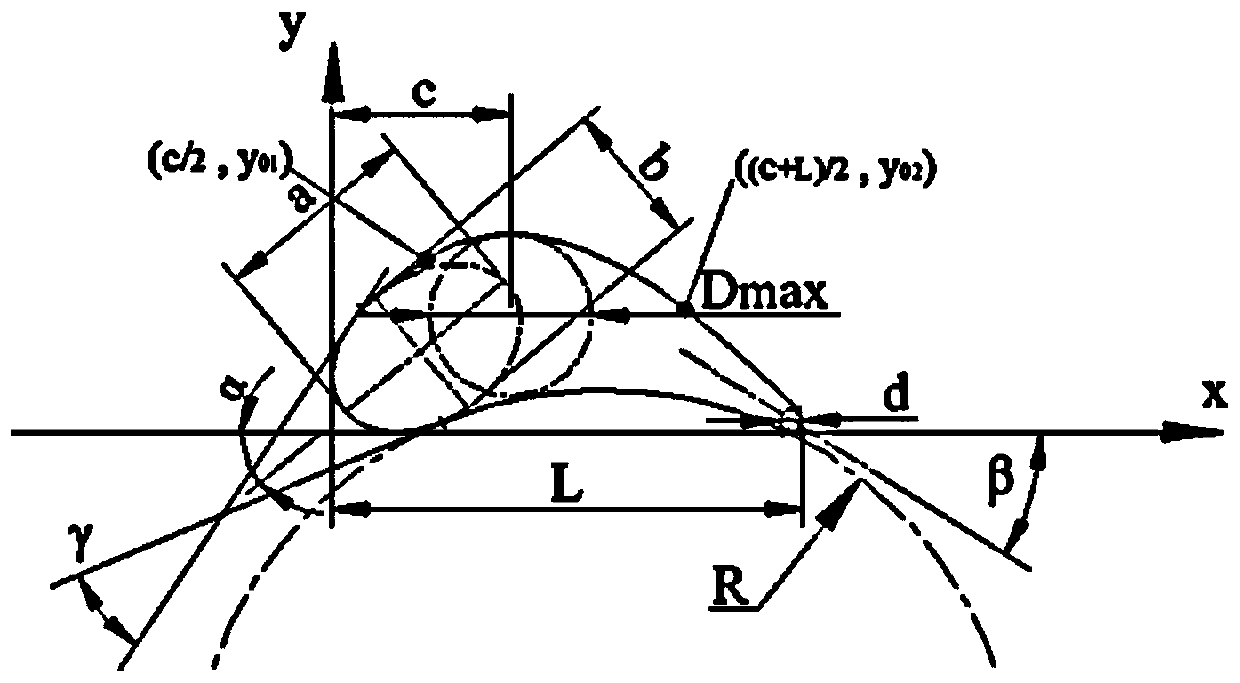

[0028] like figure 1 As shown, a steam turbine single-arc pressure surface airfoil design method is composed of the following modules: the existing single-arc pressure surface airfoil database, the conventional airfoil geometric characteristic parameter database; the twelve-parameter single-arc Pressure surface airfoil construction module; new single-arc airfoil modeling module; existing airfoil single-arc parameterization module; plane cascade CFD calculation module. The above modules iterate each other until the airfoil performance parameters meet the design requirements. The steps are:

[0029] Step 1: Transmit the blade modeling requirements to the geometric feature parameter database of the existing single-arc pressure surface airfoil and conventional...

Embodiment 2

[0037] Parametric fitting is carried out on the existing airfoil of a certain drum stage of a steam turbine, and the isentropic efficiency of this airfoil is 97.5%.

[0038] A method for designing a single-arc pressure surface airfoil of a steam turbine, the method is composed of the following modules:

[0039] Existing single-arc pressure surface airfoil database, conventional airfoil geometric feature parameter database; 12-parameter single-arc pressure surface airfoil construction module; new single-arc airfoil modeling module; existing airfoil single-arc parameterization Module; plane cascade CFD calculation module. The above modules iterate each other until the airfoil performance parameters meet the design requirements. The steps are:

[0040] Step 1: Transmit the blade modeling requirements to the geometric feature parameter database of the existing single-arc pressure surface airfoil and conventional airfoil, and screen the geometric feature parameter boundaries of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com