Cam type downward pressing testing mechanism for liquid crystal screen PCB (Printed Circuit Board) connector

A PCB board and connector technology, applied in the field of cam-type press-down testing mechanism, can solve the problems of complex mechanism, low efficiency, cumbersome control, etc., and achieve the effects of simple operation, improved work efficiency, and reduced manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

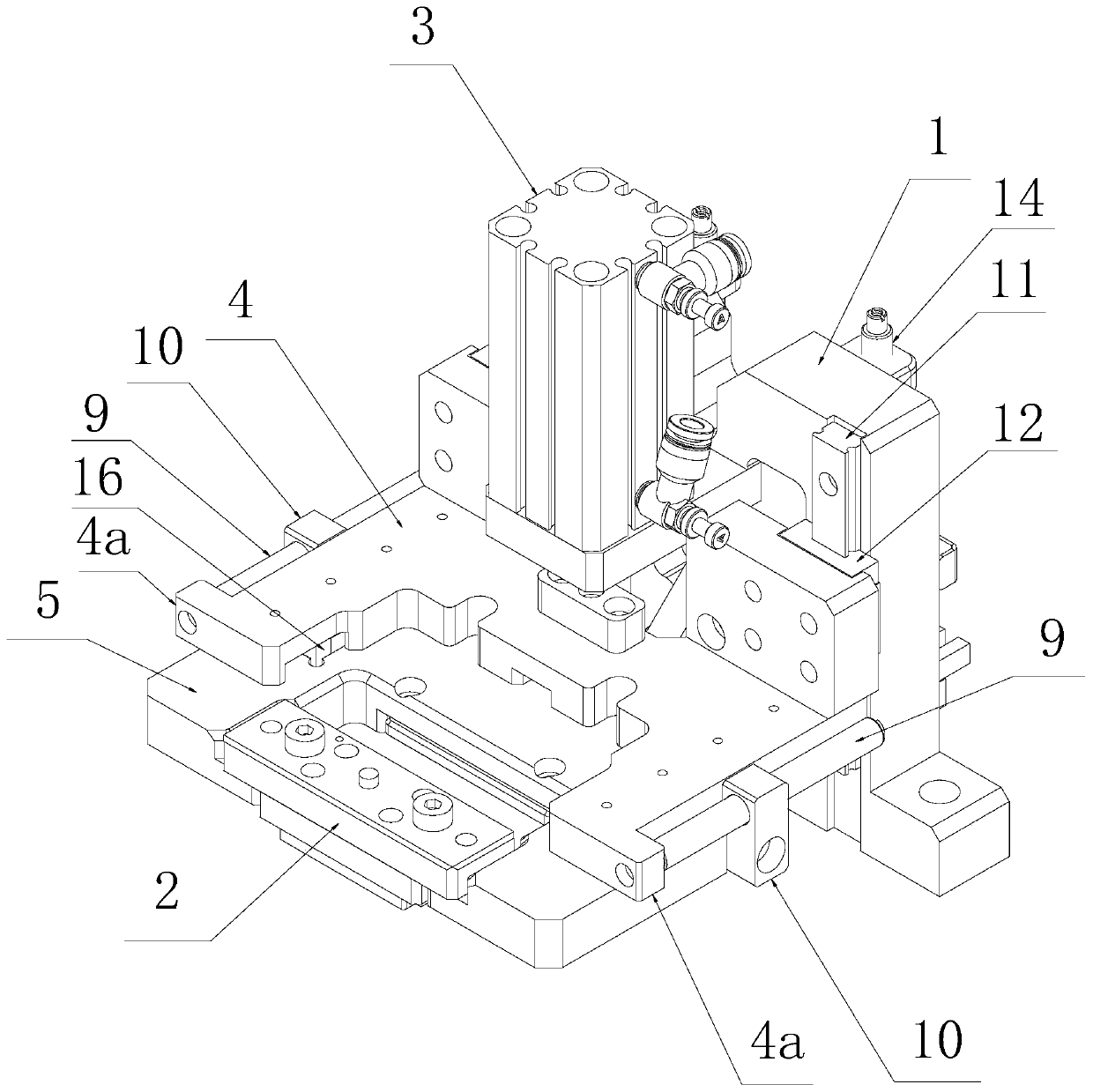

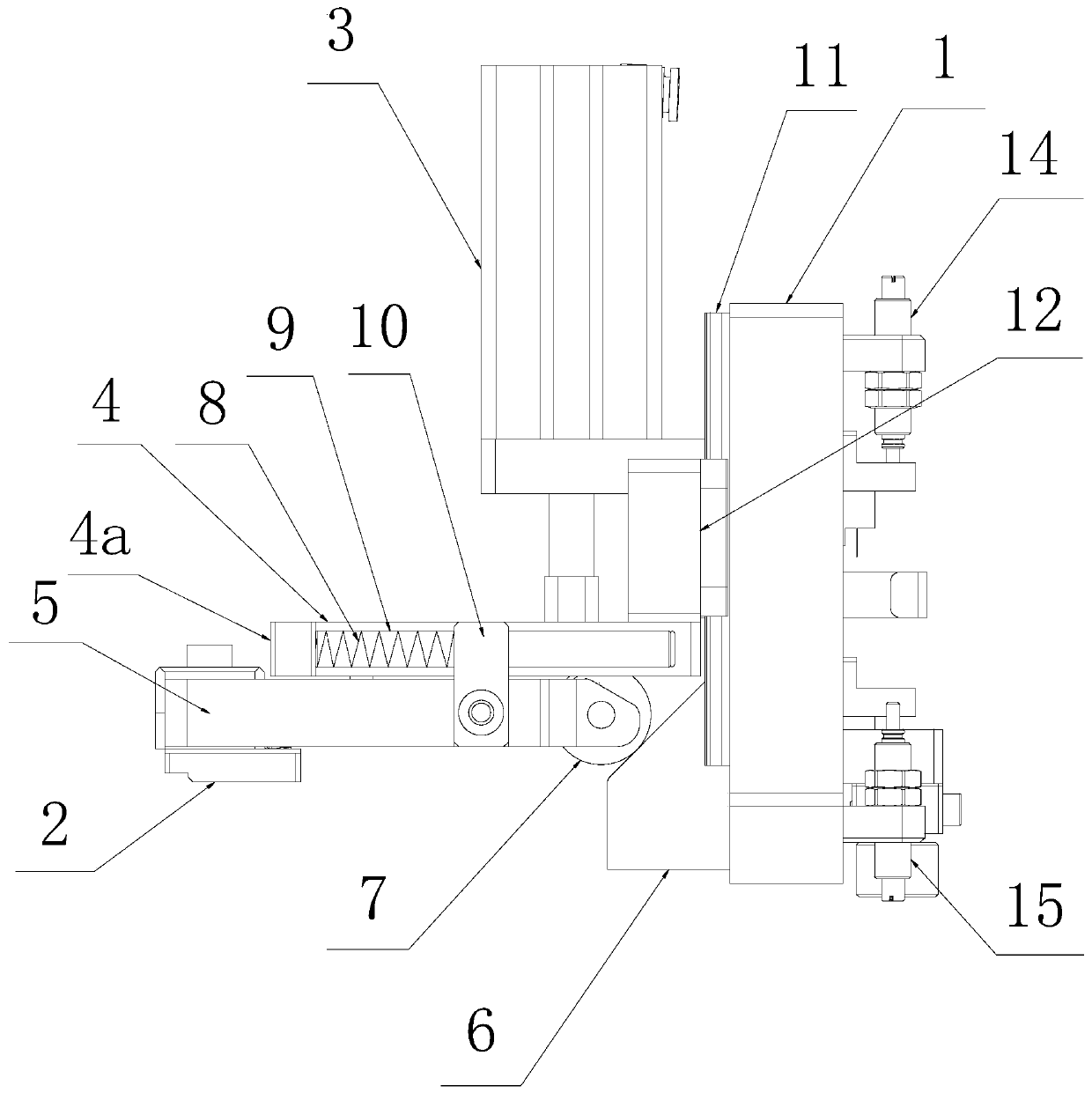

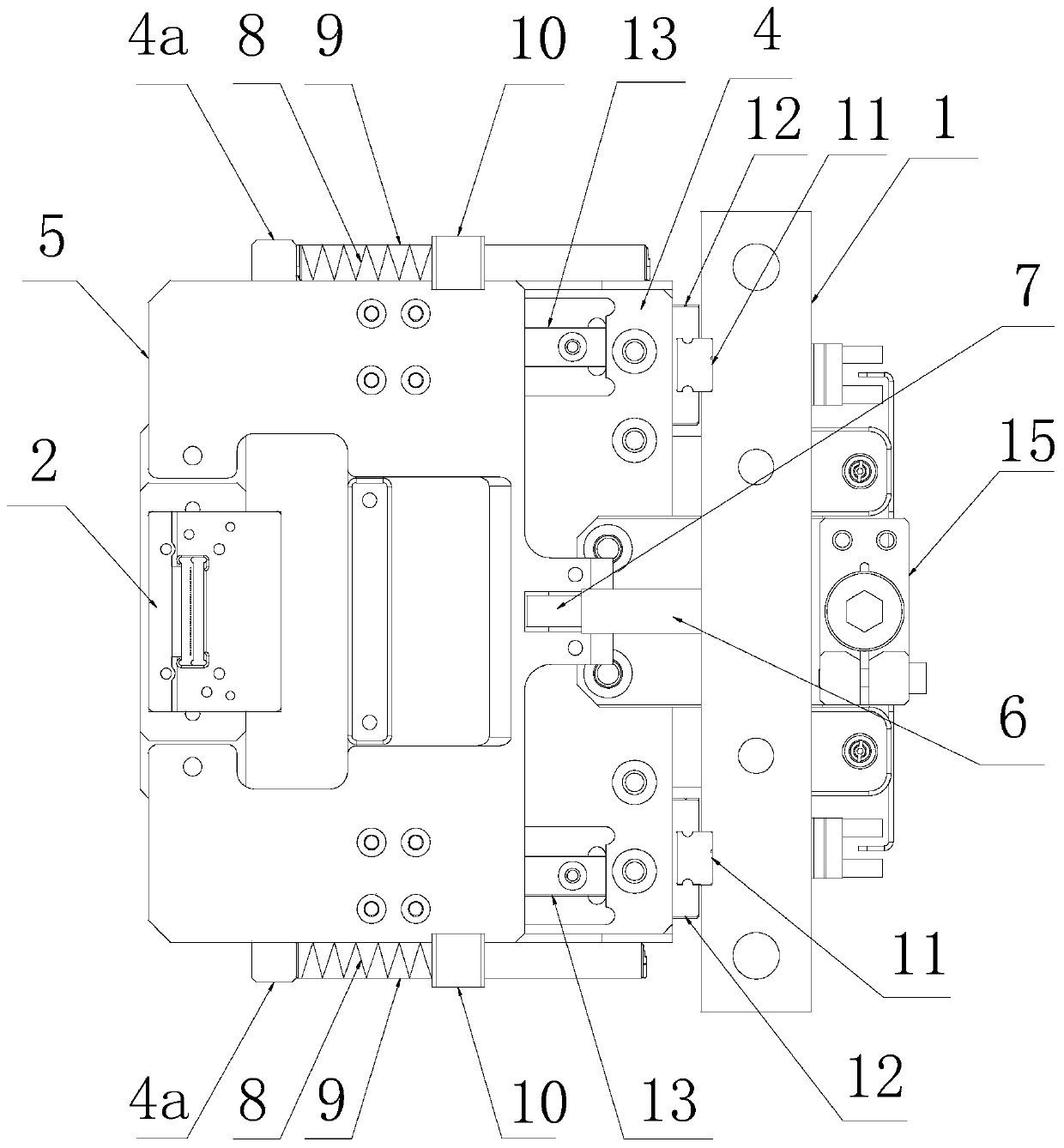

[0029] Example: Combine Figure 1~Figure 3 As shown, the specific implementation of the cam type press-down test mechanism of this liquid crystal screen PCB board connector provided by the present invention is described as follows:

[0030] It consists of machine base 1, test pressure head 2, downward pressure cylinder 3, first carrier plate 4, second carrier plate 5, cam block 6, rolling element 7, elastic reset member 8, horizontal guide rod 9, translation block 10, Vertical guide rail 11, vertical guide slider 12, horizontal guide rail 13, upper buffer 14, lower buffer 15 and horizontal guide slider 16 are jointly formed.

[0031] The machine base 1 adopts an upright form, and the downward pressure cylinder 3 is fixed on the front of the machine base 1. The ejector rod of the downward pressure cylinder 3 is connected with the first carrier plate 4 to drive the first carrier plate 4 to move in the vertical direction. The test pressure head 2 Fixed on the second carrier plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com