On-site rapid non-destructive testing method for adhesive performance of waterproof adhesive layer

A non-destructive testing, waterproof and sticky technology, applied in the direction of measuring devices, instruments, mechanical devices, etc., can solve problems such as deviation, economic waste, and damage to existing bridge deck pavement, to solve inaccurate results, improve efficiency and accuracy the effect of avoiding serious damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

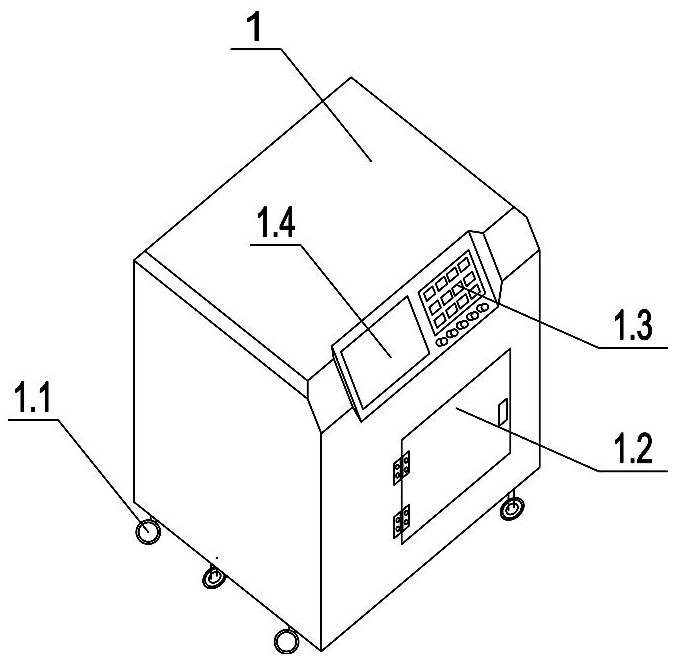

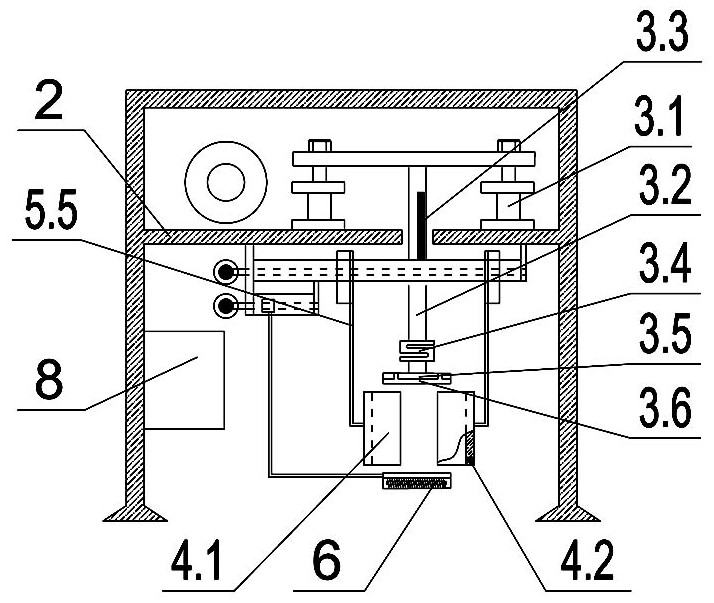

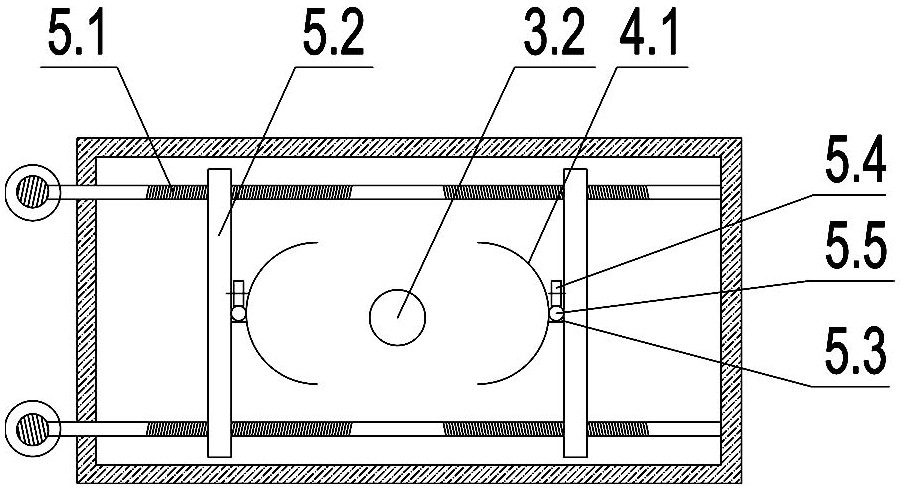

[0027] The on-the-spot rapid non-destructive testing method of the bonding performance of the waterproof adhesive layer according to the present invention is as follows: figure 1 , 2 The detection device shown includes a housing 1 with an open bottom, and a self-locking universal wheel 1.1 is installed at the bottom of the housing 1 for easy movement. A pull rod 3.2 driven by a cylinder 3.1 is installed on the bracket 2 in the housing, a displacement sensor 3.3 and a pull pressure sensor 3.4 are installed on the pull rod 3.2, and the bottom plate 3.5 of the pull rod 3.2 is connected to the pull plate 3.6 by bolts. The pull plate 3.6 is used to connect the Marshall test piece M. In order to facilitate the connection of the bottom plate 3.5 and the drawing plate 3.6, the shell 1 is provided with a furnace door 1.2 at a corresponding position. A pair of circular half cylinders 4.1 connected to the lifting opening and closing mechanism are installed symmetrically on both sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com