Garment treatment equipment

A clothing treatment device and a technology for lint, applied in the field of clothing treatment, can solve the problems of inability to remove the lint filter, gaps, noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

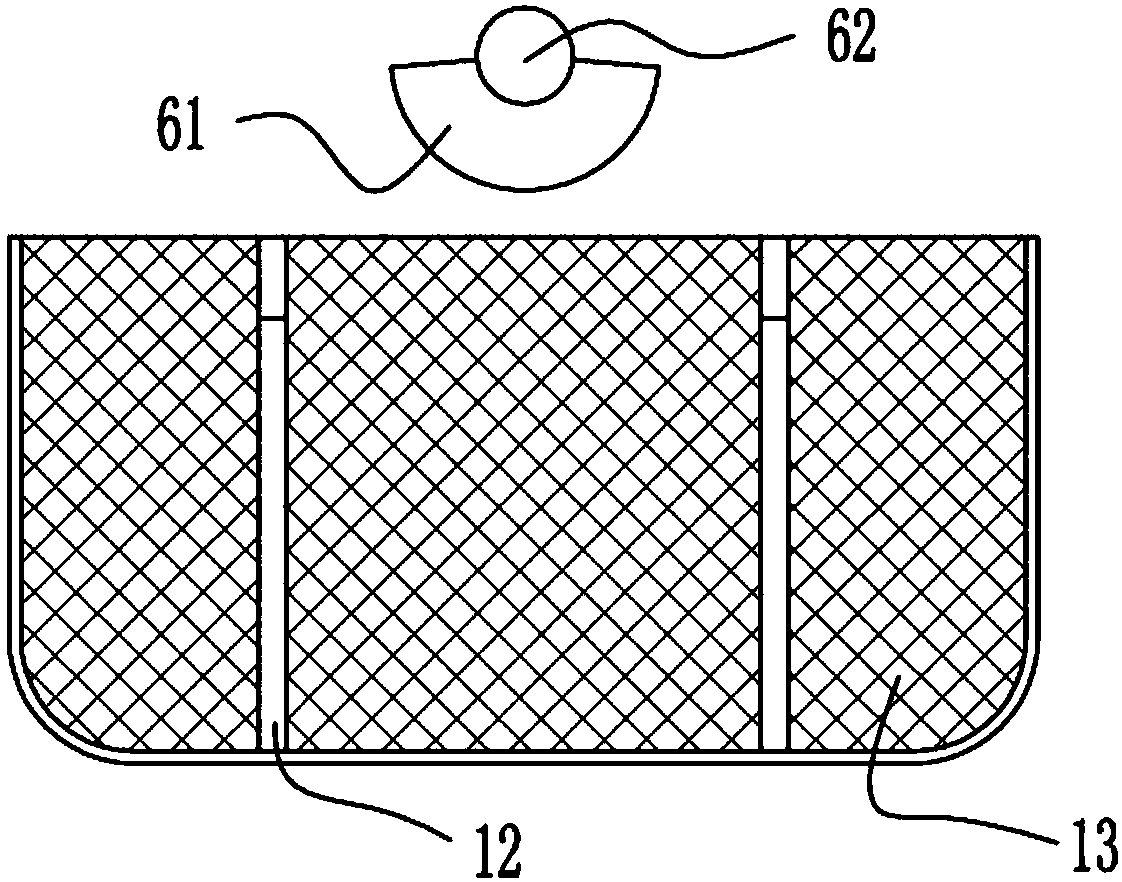

[0069] like figure 1As shown, in the laundry processing equipment described in this embodiment, the cleaning device cleans the lint filtering device by spraying a cleaning medium. The cleaning device includes a spray part 61 and a guide part 62 penetrating inside, so that a channel for conducting fluid flow is formed inside the spray part 61 and the guide part 62 . The cleaning device can spray cleaning media with a covering direction within a certain angle range to the lint filter device, and the cleaning device adjusts the range of the covering direction, thereby adjusting the cleaning range. For example, when the cleaning device starts to clean the lint filtering device, the vibration of the lint filtering device is more severe at this time, indicating that there are more lint attached to it, which affects the progress of the filtering process, and the cleaning device expands its spraying capacity. The coverage of the cleaning medium increases the cleaning range of the lin...

Embodiment 2

[0072] The difference between the laundry treatment device described in this embodiment and the above embodiments is that the cleaning device can adjust the direction in which it sprays the cleaning medium, thereby adjusting the cleaning range. For example, during implementation, when the vibration detection device detects that the vibration of the lint filtering device exceeds a specified value, the control system controls the cleaning device to start working, but its working range only covers a part of the lint filtering device, which can be relatively In the range of 0°-90° in the horizontal direction, that is, relative to figure 1 For the lint filtering device in the right half of the structure shown, after the cleaning of this part of the lint filtering device is completed, the range of 90°-180° relative to the horizontal direction is cleaned. At this time, the right side of the lint filtering device The half is cleaned and finished to fully perform the filtering function...

Embodiment 3

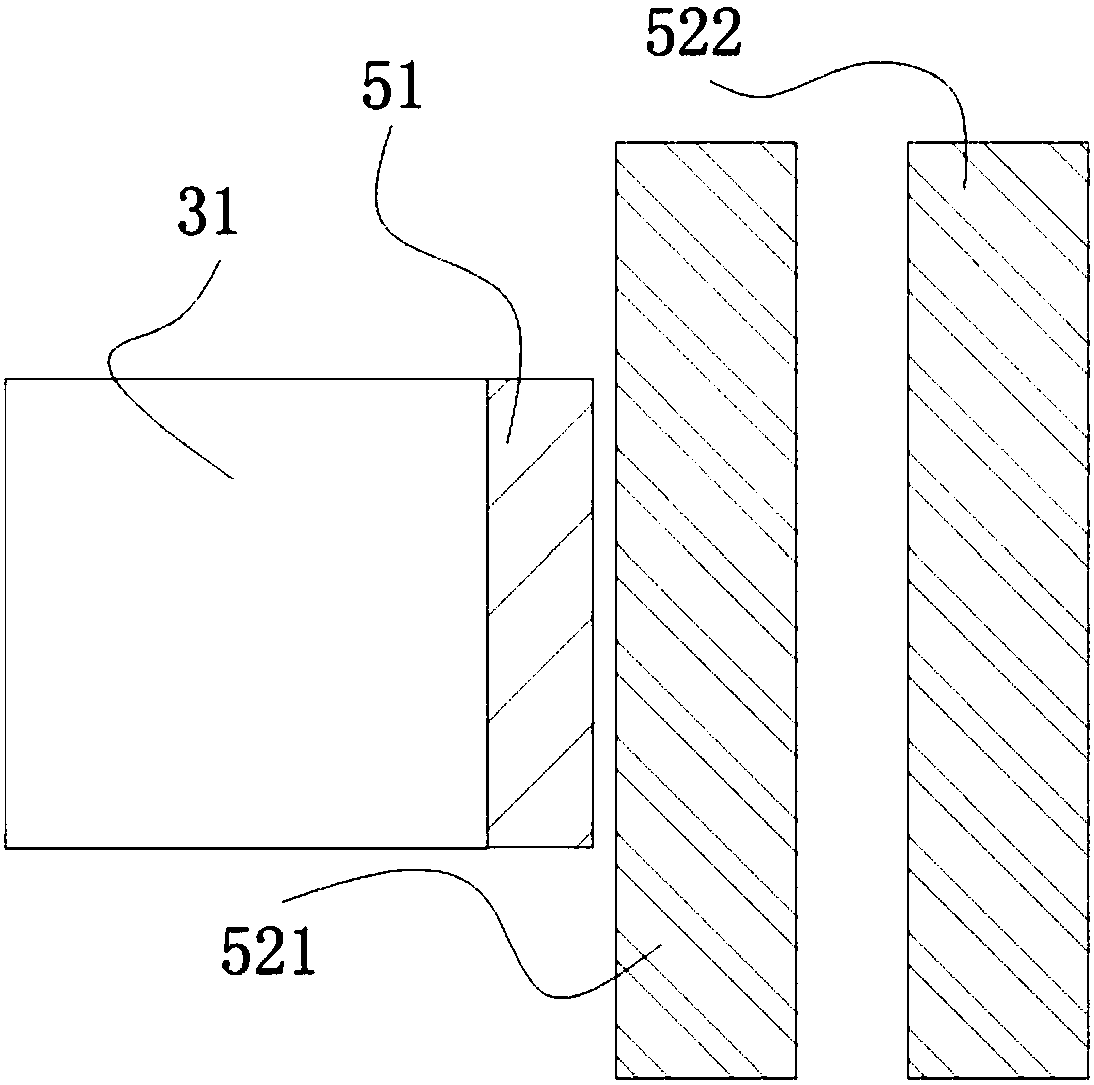

[0075] The difference between the laundry treatment device in this embodiment and the above embodiments is that: the cleaning device further includes a control unit for controlling the opening and closing of the channel and / or adjusting the flow rate of the cleaning medium in the channel. The cleaning device can adjust the force of spraying the cleaning medium, and then adjust the force of the cleaning medium to wash away the lint filtering device. The cleaning device adjusts the washing force of the cleaning medium on the lint filtering device by adjusting the flow rate of the cleaning medium in the channel. For example, at the beginning of the cleaning operation of the cleaning device, since there are more lint attached to the lint filtering device at this time, a greater impact force is needed to wash it off the lint filtering device; If it is carried out gradually, there is no need to perform a strong impact on the lint filtering device, and at this time, the cleaning forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com