Speed-variable cutting integrated paper feed roll for paper machine

An integrated paper feed roller technology, which is applied in the field of variable-speed cutting integrated paper feed rollers for paper machines, can solve the problems that the cutting knives cannot be quickly and synchronously matched, labor is laborious, and the cutting position of the cutting knives is not accurate enough, etc., and the failure rate is small , improve efficiency, and achieve a high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

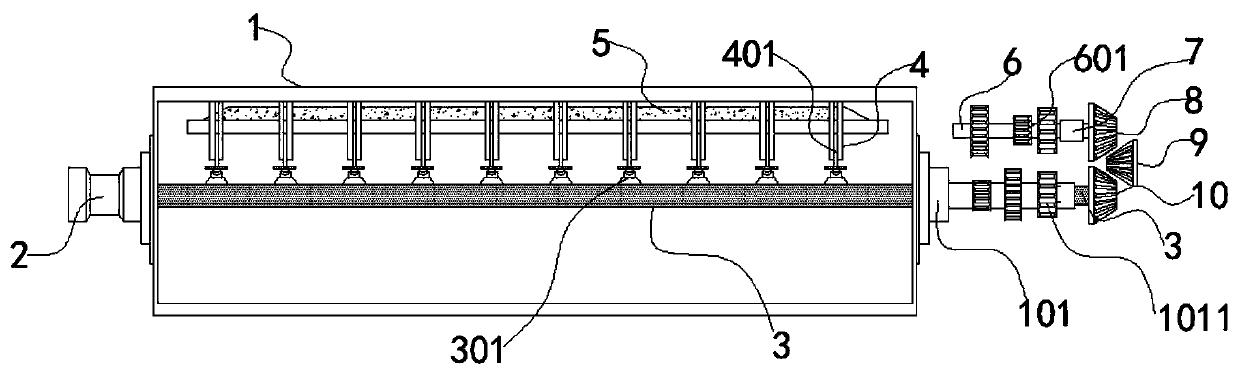

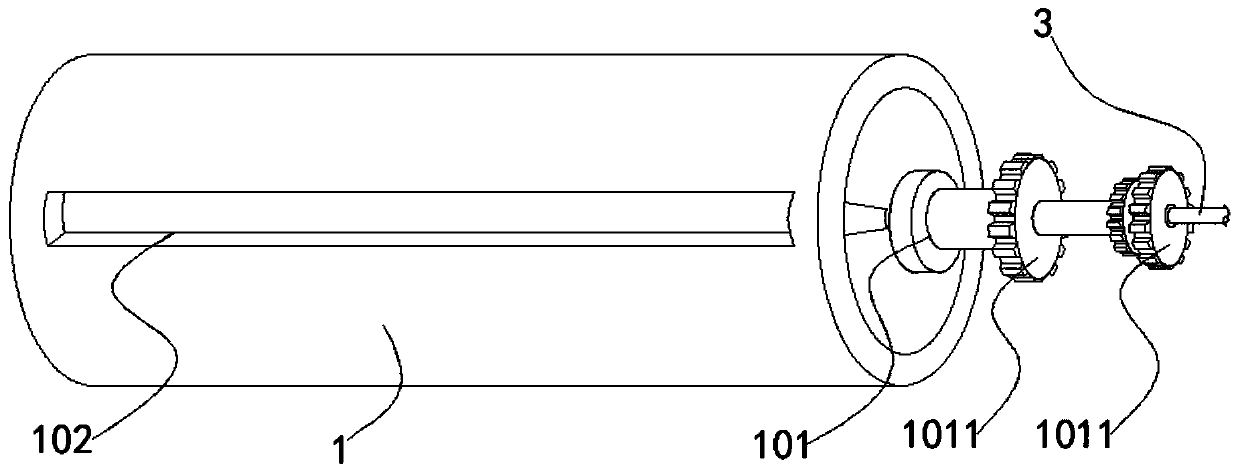

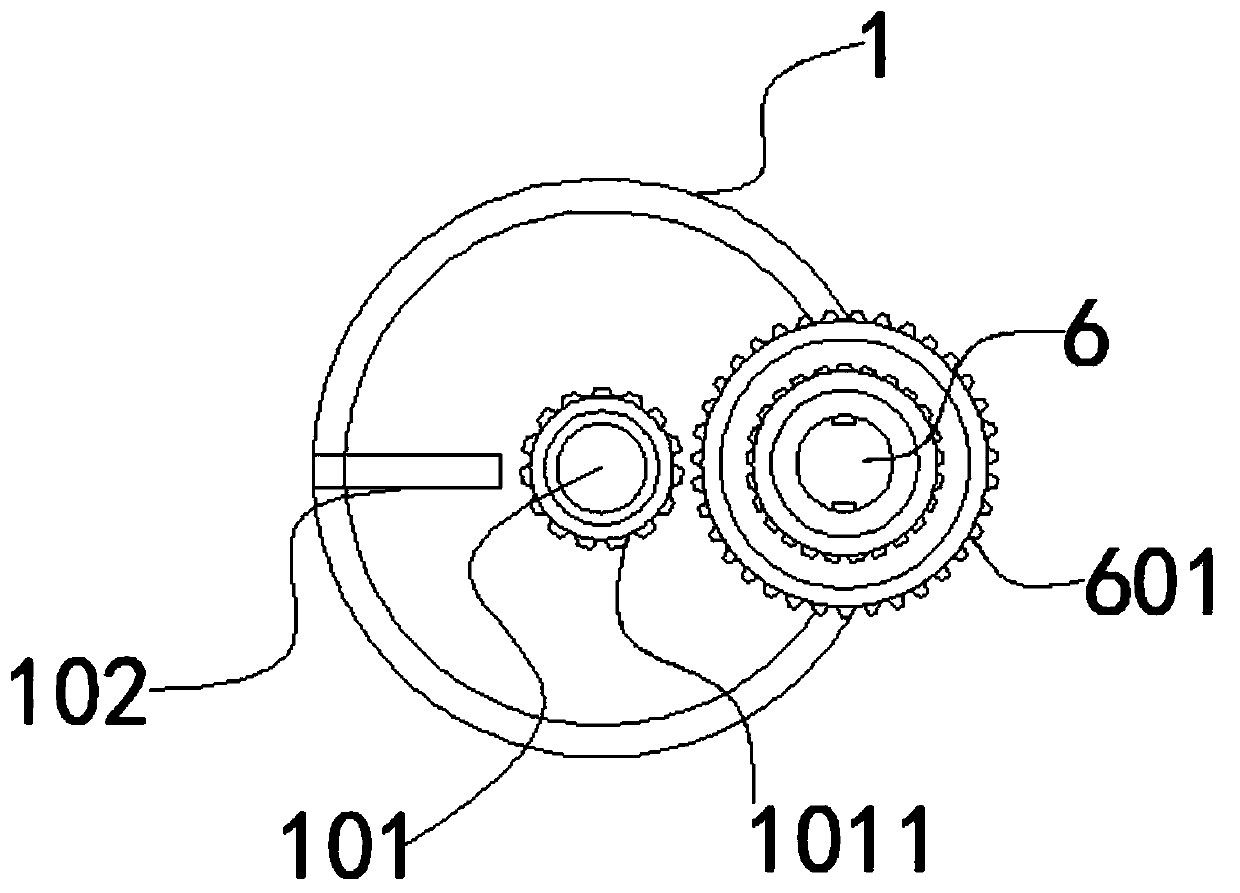

[0030] as attached figure 1 to attach Figure 7 Shown:

[0031] The invention provides a variable-speed cutting integrated paper feed roller for a paper machine. The variable-speed cutting integrated paper feed roller for a paper machine includes a paper feed roller 1, a pulley 2, a linkage rod 3, a limit guide groove 4, and a cutting knife 5. Shift sleeve rod 6, limit telescopic sleeve 7, first right-angle transmission gear 8, second right-angle transmission gear 9, third right-angle transmission gear 10, output end rod 101, cutting port 102, fixed gear 1011, contact surface 301 , piston rod 401, passive plate 4011, speed change gear 601, linkage limit tooth 602 and linkage limit groove 701; paper feed roller 1 surface opening is provided with cutting opening 102, and paper feed roller 1 side is integrally provided with pulley 2, The other side of the paper feed roller 1 is integrally provided with an output end rod 101, the surface of the output end rod 101 is integrally p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com