Steam generating device and steam cooking equipment using same

A technology of steam generating device and cooking equipment, which is applied in the field of steam cooking equipment and steam generating device, and can solve the problems of waiting for a long time and taking a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

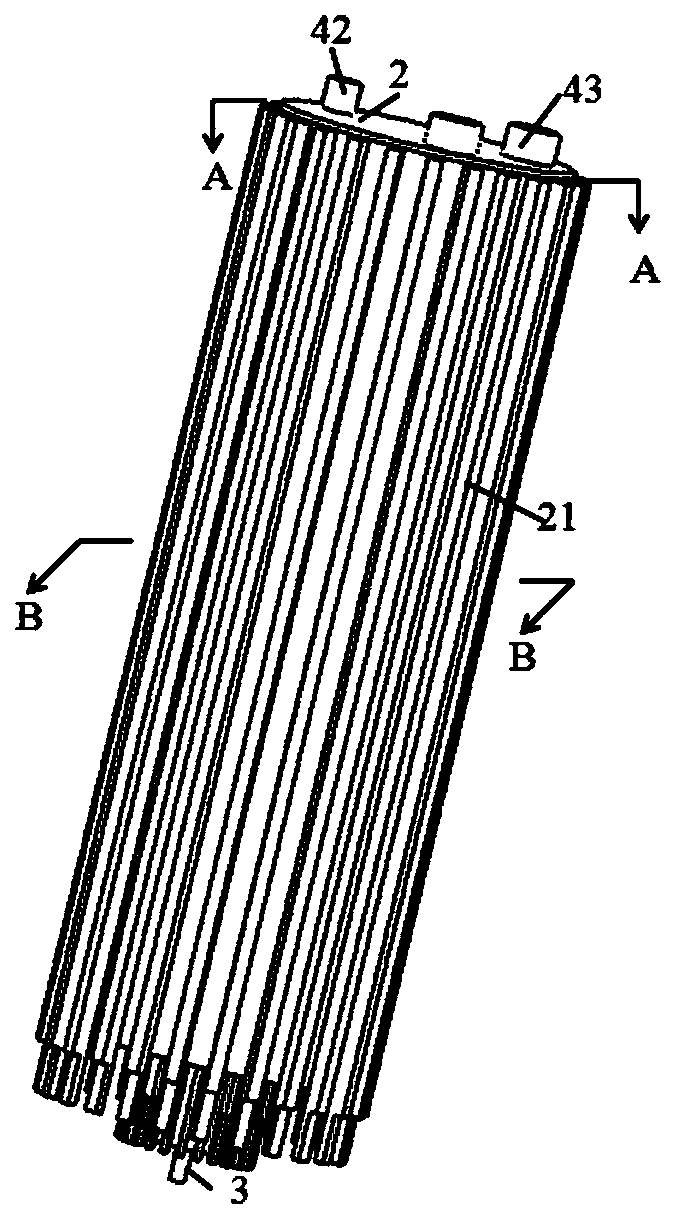

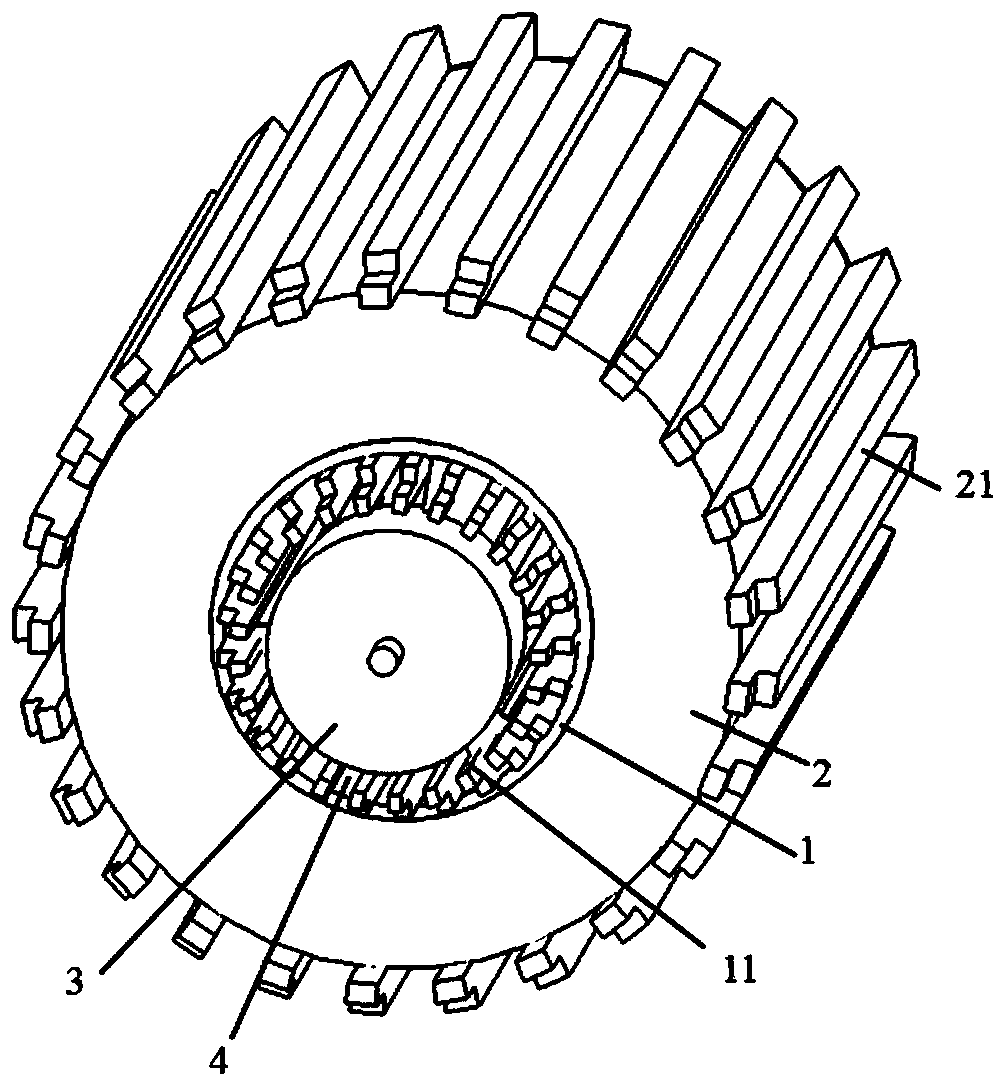

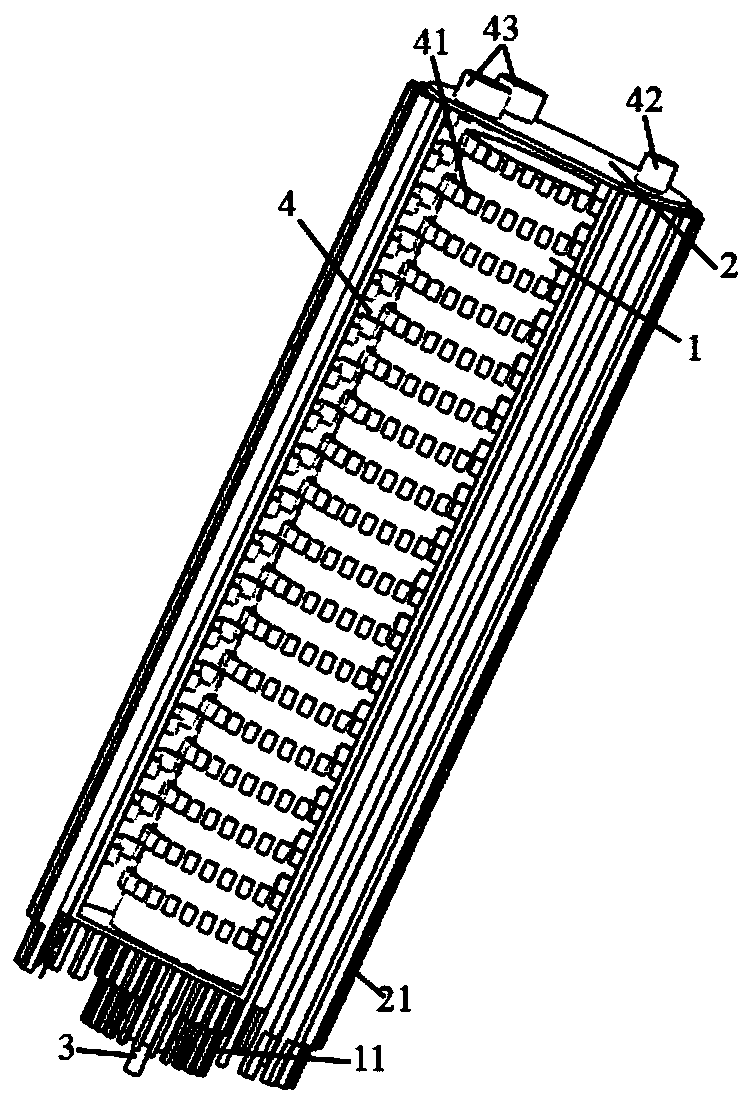

[0030] This embodiment provides a steam generating device, such as Figure 1-Figure 6 As shown, it includes a vertically arranged heating inner cylinder 1, a vertically arranged heating outer cylinder 2, a drive assembly 3 and an annular cylindrical water storage chamber 4 for generating steam;

[0031] The heating inner cylinder 1 is arranged in the heating outer cylinder 2, and the cavity formed between the heating inner cylinder 1 and the heating outer cylinder 2 is a water storage chamber 4. The drum 2 rotates with a drive assembly 2 .

[0032] Because the heating inner cylinder 1 and the heating outer cylinder 2 are arranged vertically, and the cavity formed between the heating inner cylinder 1 and the heating outer cylinder 2 is the water storage chamber 4, the water entering the water storage chamber 4 will Under the action of gravity, it flows to the bottom of the water storage chamber 4; because both the heating inner cylinder 1 and the heating outer cylinder 2 can h...

Embodiment 2

[0052] This embodiment also provides a steam cooking device using Embodiment 1, such as Figure 7 As shown, it includes a steam cooking device body 5, and the steam generating device communicates with the steam cooking device body 5;

[0053] Because the steam cooking equipment adopts the steam generating device of embodiment 1, and the steam generating device of embodiment 1 takes less time to generate steam compared with the existing steam generator, the steam generating device of embodiment 1 is used When the steam cooking equipment steams food, it can solve the problem that the existing steam cooking equipment needs to wait for a long time in the process of steaming food.

[0054] The working process of the steam cooking equipment of the present embodiment is:

[0055] Start the steam cooking equipment of this embodiment, water flows into the water storage chamber 4 from the water inlet 42, and the driving assembly 3 (motor) starts running at the same time, the driving as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com