Herbage crushing and processing device with elastic screening function

A processing device and a spring-type technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of low efficiency of processing and crushing, long time consumption, and difficulty in sieving, so as to promote screening, promote material passing, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

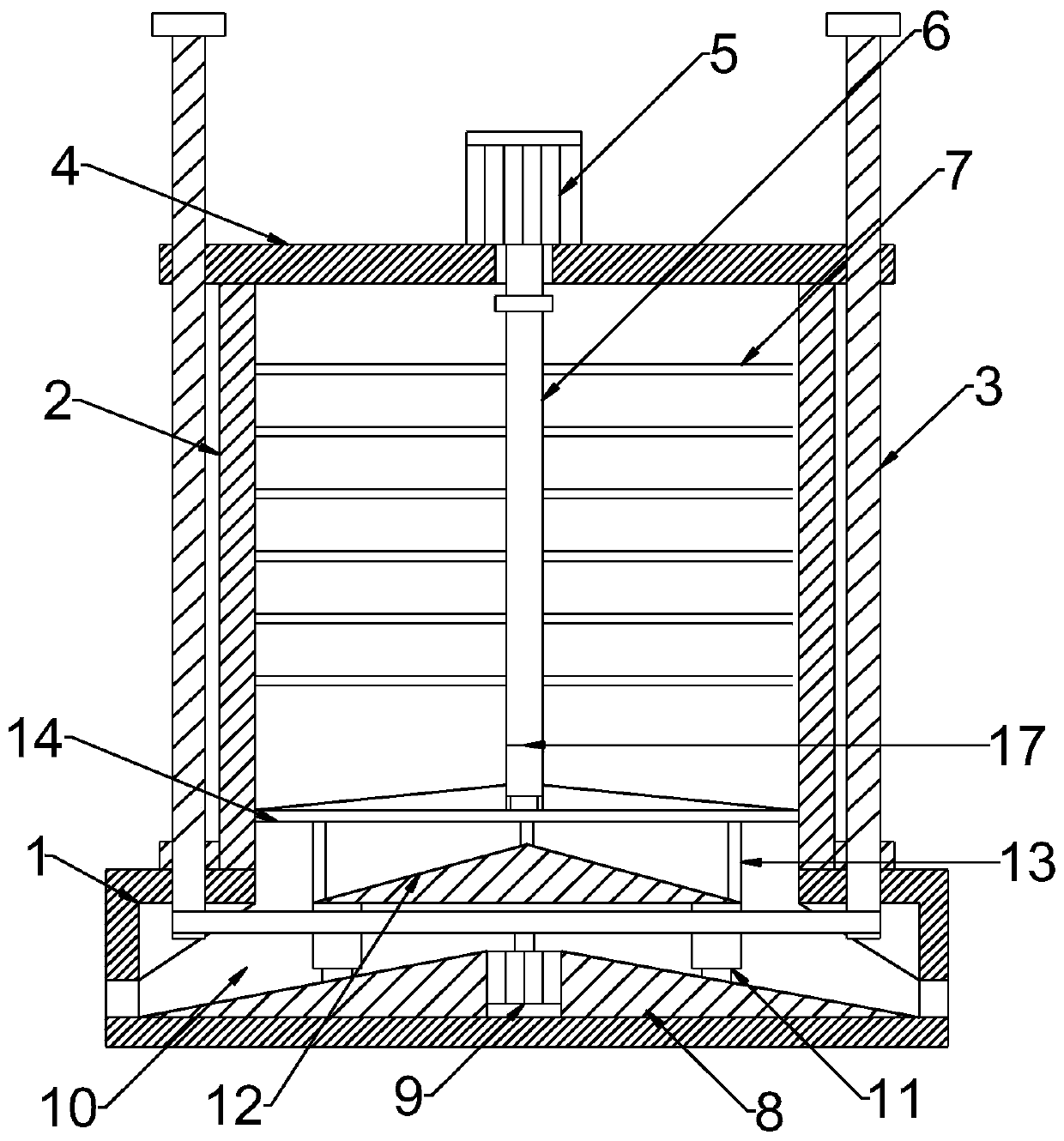

[0021] see figure 1 , in an embodiment of the present invention, a pasture crushing and processing device for bouncing screening, comprising a base 1 and a crushing chamber 2 arranged in communication, the upper end of the crushing chamber 2 is fitted with an upper cover 4, and the upper cover 4 is There is a crushing structure extending into the crushing chamber 2, the bottom of the base 1 is provided with a material guide structure, the upper end of the material guide structure is connected with a screen 14 through an elastic support structure, and the two sides of the upper cover 4 are also arranged symmetrically. There is a lifting rod 3, the lifting rod 3 runs through the upper cover 4 through screw fit, and the end runs through the base 1 through the bearing rotation, and the end of the lifting rod 3 far away from the upper cover 4 is connected to the first through a belt transmission mode. The second motor 9 is connected to the transmission.

[0022] The crushing struc...

Embodiment 2

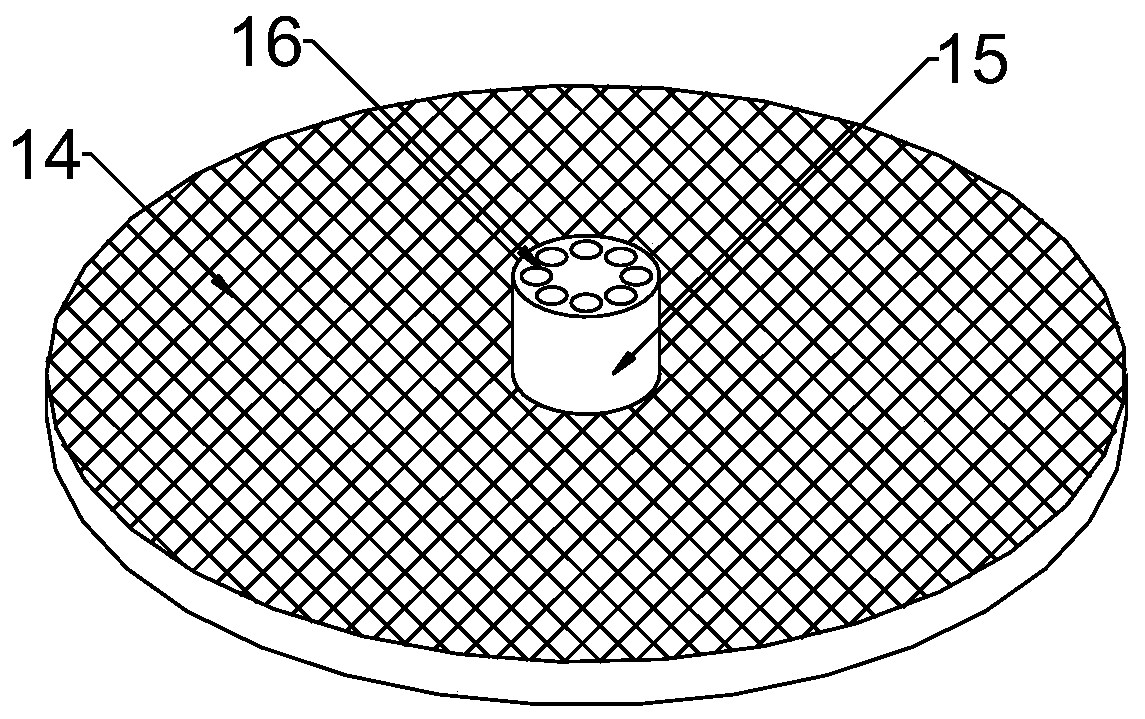

[0027] see Figure 2~3 , in the embodiment of the present invention, a kind of pasture pulverizing processing device of bouncing type screening, on the basis of embodiment 1, the center of the upper end of the screen 14 is also fixedly connected with a boss 15, and the boss 15 is Cylindrical protruding structure, the upper surface of the boss 15 is embedded with a plurality of groups of ball holes 16 in an annular array, and the ball holes 16 are semi-spherical depressions.

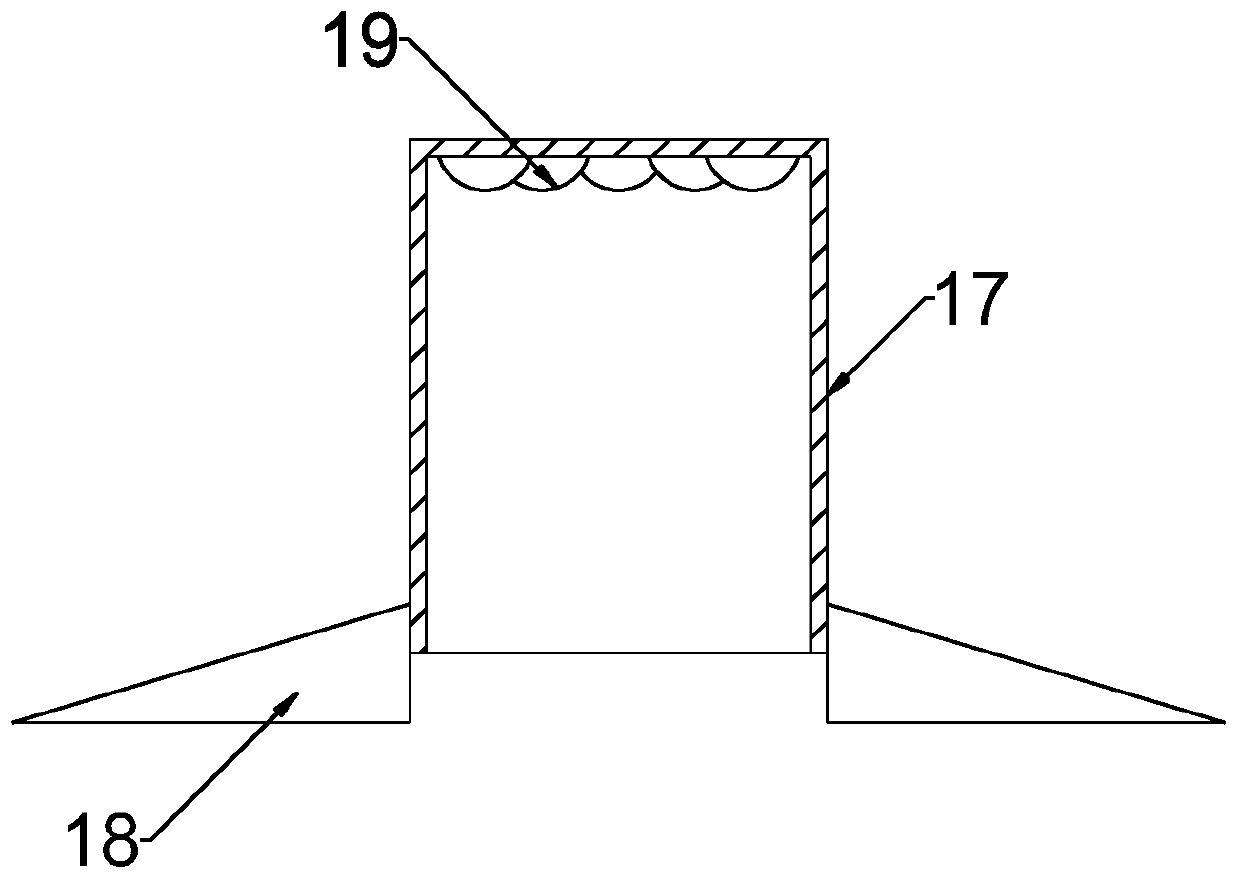

[0028] The lower end of the rotating shaft 6 is fixedly connected with a sleeve 17, the sleeve 17 is a cylindrical structure, and the inner top of the sleeve 17 is provided with a plurality of sets of protrusions 19 in an annular array, and the periphery of the sleeve 17 is welded and fixed. There are multiple sets of scraper rods 18, which are movably attached to the upper surface of the screen 14, and the scraper rods 18 are triangular structures with opening side edges on both sides.

[0029] The slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com