Coal blending combustion intelligent management method and system

A technology of intelligent management and coal blending, applied in information technology support systems, data processing applications, forecasting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

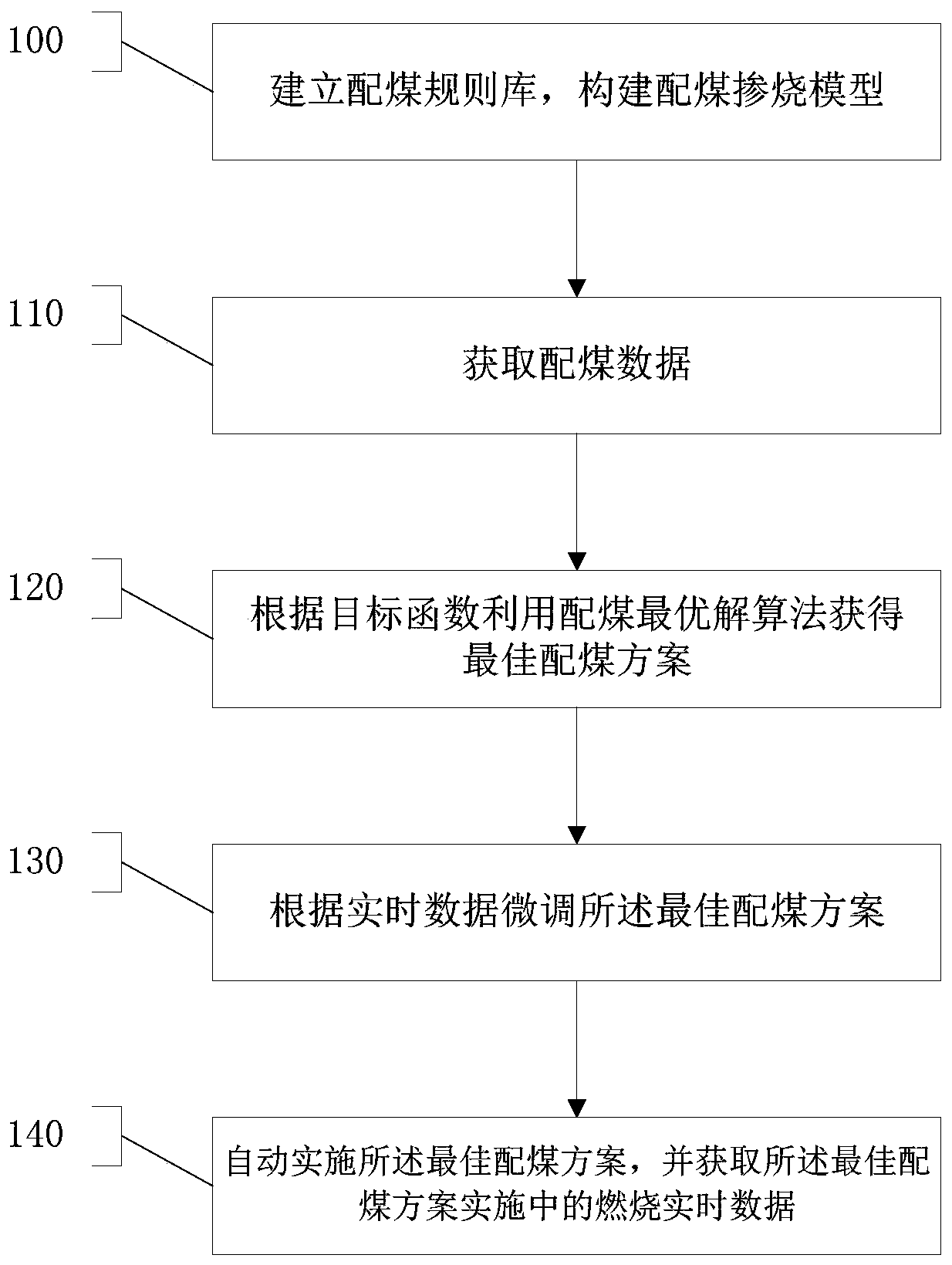

[0086] Such as figure 1 , figure 2 As shown, step 100 is executed, and the model construction module 200 establishes a coal blending rule library, and builds a coal blending and blending model. The coal blending model includes a set containing p independent variable parameters, a set containing K objective functions and A combination of L constraints is mathematically described as follows: Among them, x is the independent variable vector, y=y 1 +y 2 is the target vector, y 1 The indices in are called negative indices, y 2 The index in is called positive index, f(x) is the objective function, and the restriction condition is: g(x)=(g 1 (x), g 2 (x),...,g L (x))≤0, g(x) is a constraint condition, which is used to limit the feasible domain. Under the framework of the multi-objective optimization mathematical model, the multi-objective coal blending model includes basic parameters, constraints and objective functions. The basic parameters include the calorific value Q...

Embodiment 2

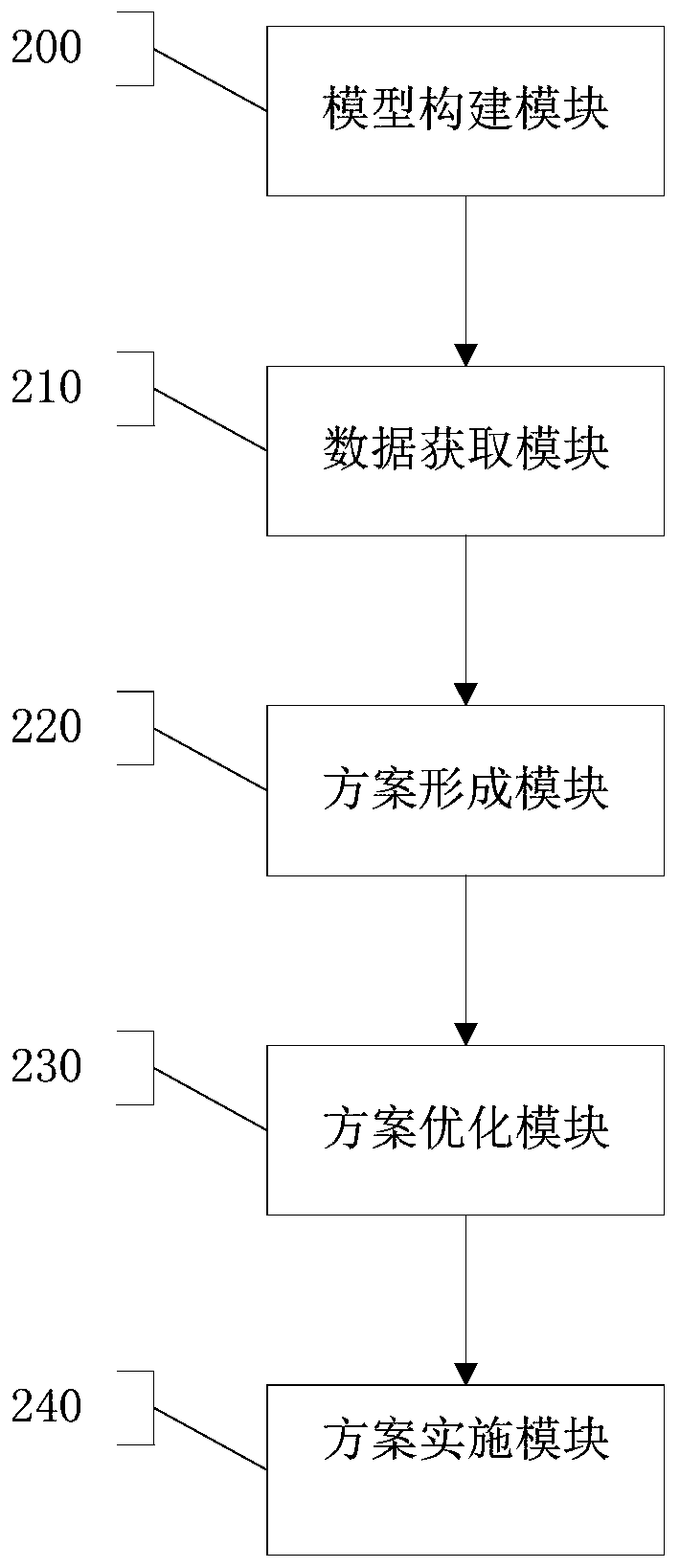

[0090] The present invention provides an intelligent management system for coal blending and blending combustion. Through the established coal blending and blending decision-making model, system process library, and coal blending rule library, the intelligent management system receives equipment-level perception signals and coal storage dynamics in coal yards. Information, coal quality information, boiler combustion demand information, and preset process library and other external interactive information are integrated and calculated, and the program-controlled operation plan of the coal-burning island is automatically generated according to the intelligent management requirements of the coal-burning island (coal receiving and unloading storage plan, distribution plan, etc.) Coal blending plan, sampling plan, etc.), early warning prompt information, event evaluation report and other decision-making and analysis instructions, and the instructions are issued to the program control...

Embodiment 3

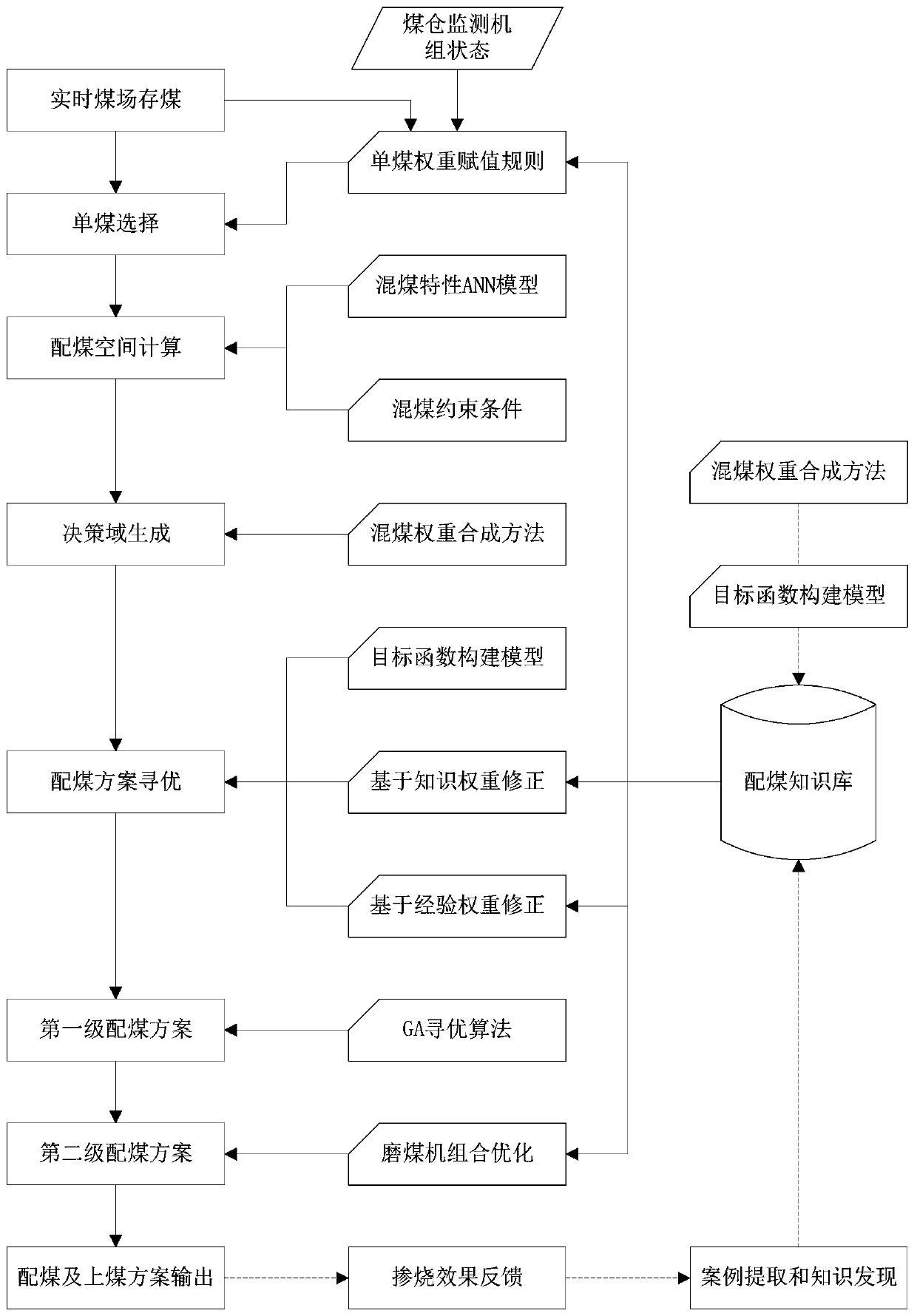

[0168] Coal blending and combustion management system, through accurate calculation of fuel blending and coal blending, lean implementation, fine management, comprehensive intelligent blending optimization model, boiler design parameters, incoming coal information, power generation plan, load distribution, coal yard inventory, historical historical distribution Coal blending evaluation, equipment operating conditions and other factors generate a comprehensive and optimal blending plan for safety, economy, and environmental protection indicators, and guide coal procurement to improve support for production and operation decisions. The coal blending and burning module is mainly composed of coal yard coal extraction rule library, coal blending and burning rule library, raw coal bunker dynamic monitoring, coal blending process management, combustion evaluation feedback, coal handling system process flow library and other modules.

[0169] The coal-fired intelligent blending system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com