Aero-engine core engine room fire full-scale test device

A technology for engine compartments and engines, applied in measuring devices, testing of machines/structural components, instruments, etc., can solve the problems that cannot truly reflect the fire and fire spread of the core engine room, and establish geometric features, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

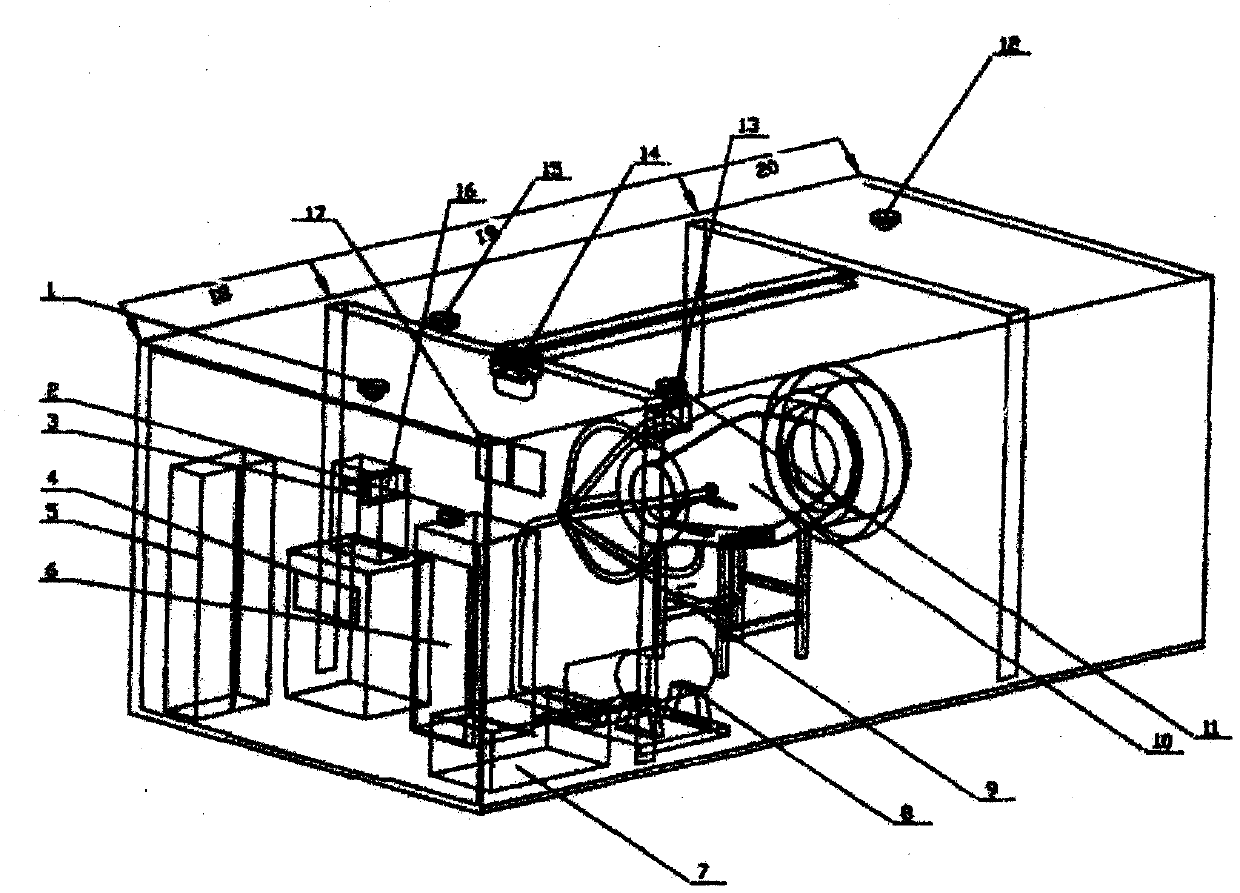

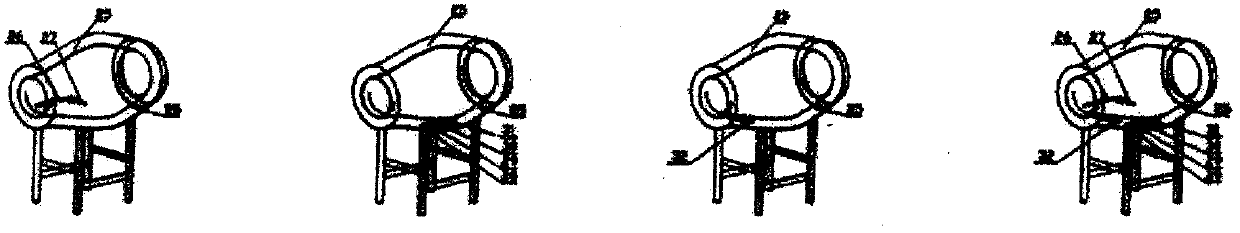

[0020] The solution of the present invention is to adopt a modular design method to divide the entire core engine room full-scale test bed into seven modules, which are test container and safety protection module, 1:1 engine room geometric model and support platform module, and inlet ventilation Control module, wall heating module, fire source module, ignition module and data acquisition module.

[0021] Preferably, the space size of the test container is a steel structure container 12m long*4m wide*5m high. Considering the safety of the test process, a fire hydrant was installed outside the test container, and CO2 automatic fire extinguishing equipment and portable fire extinguishers were installed in the container for emergency treatment of test emergencies to ensure the safety of test personnel.

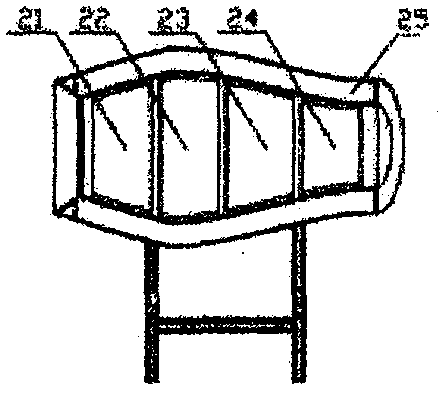

[0022] Preferably, the geometric model of the test nacelle is constructed with reference to a certain type of engine 1:1. Due to the fact that there are very complicated piping, wirin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com