Optical wavefront measuring system and optical wavefront measuring method

An optical detection and wavefront technology, applied in the field of optics, can solve the problems of temperature drift of liquid optical components, low photo definition, affecting the optical performance of liquid optical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

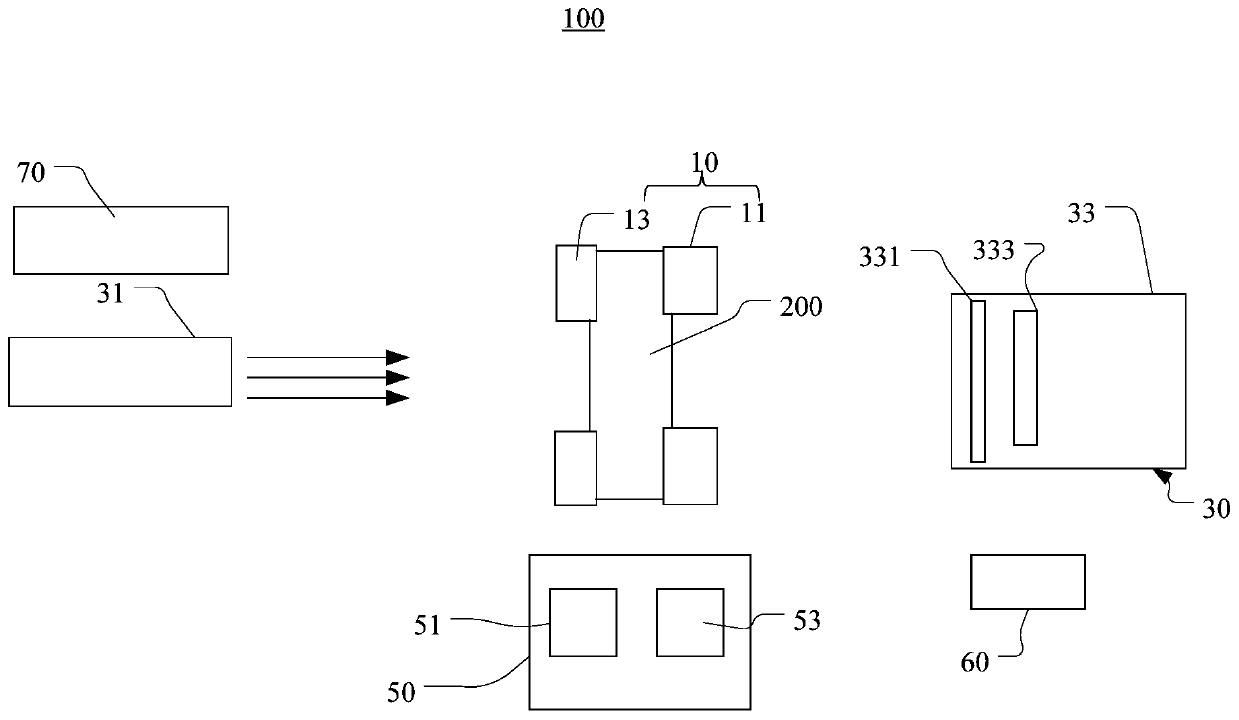

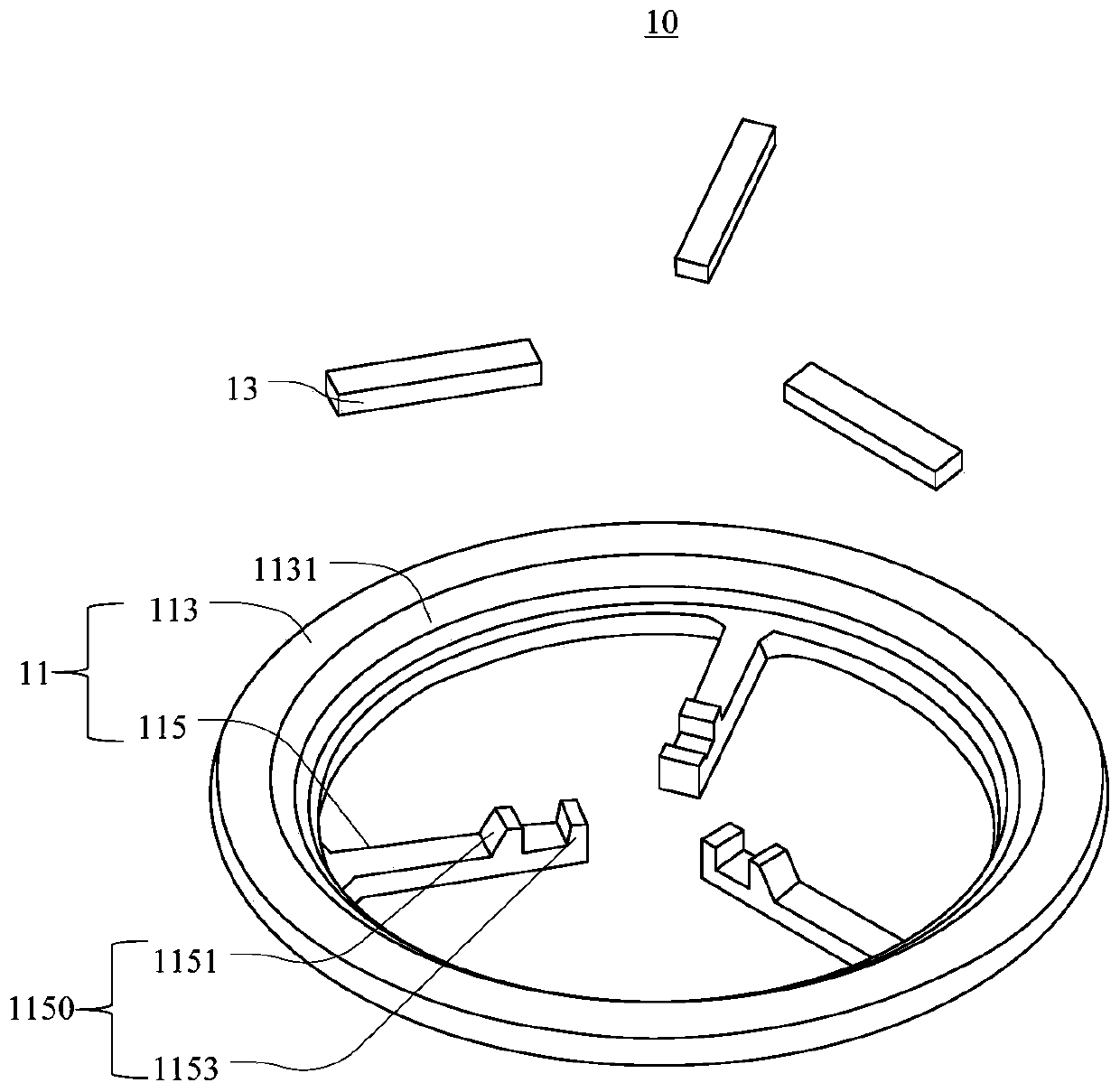

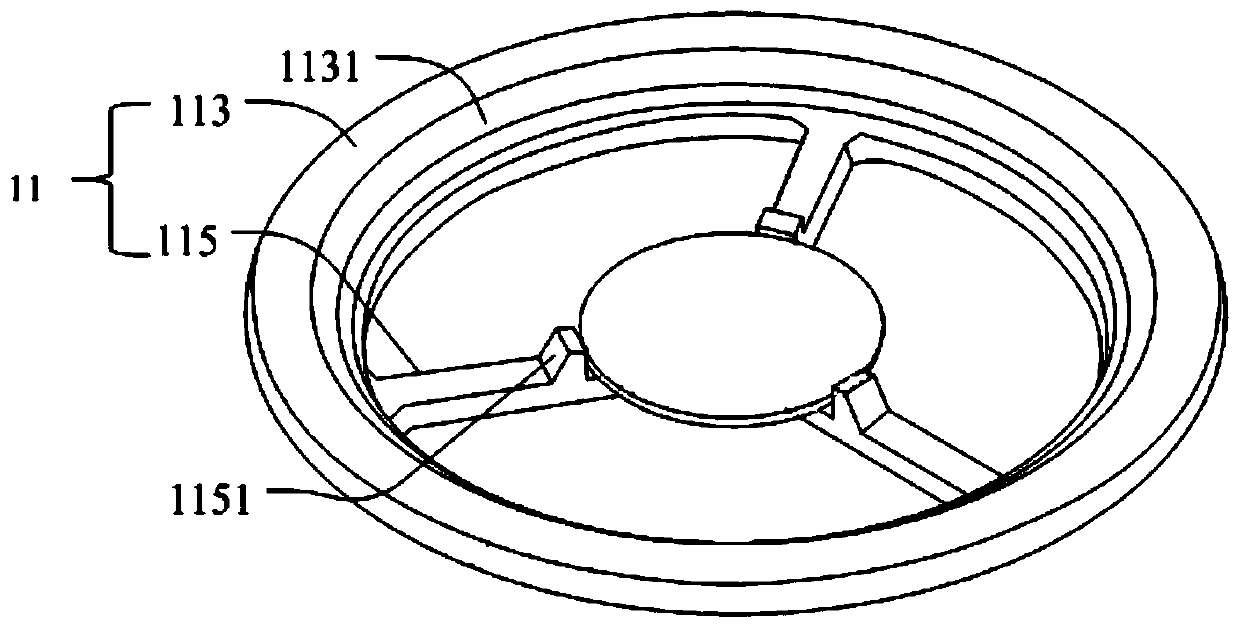

[0033] see figure 1 , figure 1 It is a schematic structural diagram of an optical wavefront measurement system provided in an embodiment of the present application. An optical wavefront measurement system 100 includes a carrier device 10 , a wavefront measurement device 30 , a temperature and humidity device 50 and a processor 60 . The carrying device 10 is used for positioning the liquid optical element 200 to be tested. The wavefront measuring device 30 is used for detecting wavefront information passing through the liquid optical element 200 . The temperature and humidity device 50 is configured to adjust the temperature of the environment where the liquid optical element 200 is located to a preset temperature, and adjust the humidity of the environment where the liquid optical element 200 is located to a preset humidity. The processor 60 communicates with the wavefront measurement device 30 and the temperature and humidity device 50 . When the processor 60 determines t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com