Buried pipeline non-contact stress real-time monitoring method

A buried pipeline and non-contact technology, which is applied in the direction of measuring, measuring devices, and measuring magnetic variables by measuring the change of magnetic properties of materials caused by applied stress. It can solve pipeline failure and fracture, limited installation and use, etc. problems, to achieve the effect of saving excavation installation costs and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

[0033] A non-contact stress real-time monitoring method for buried pipelines of the present invention comprises the following steps:

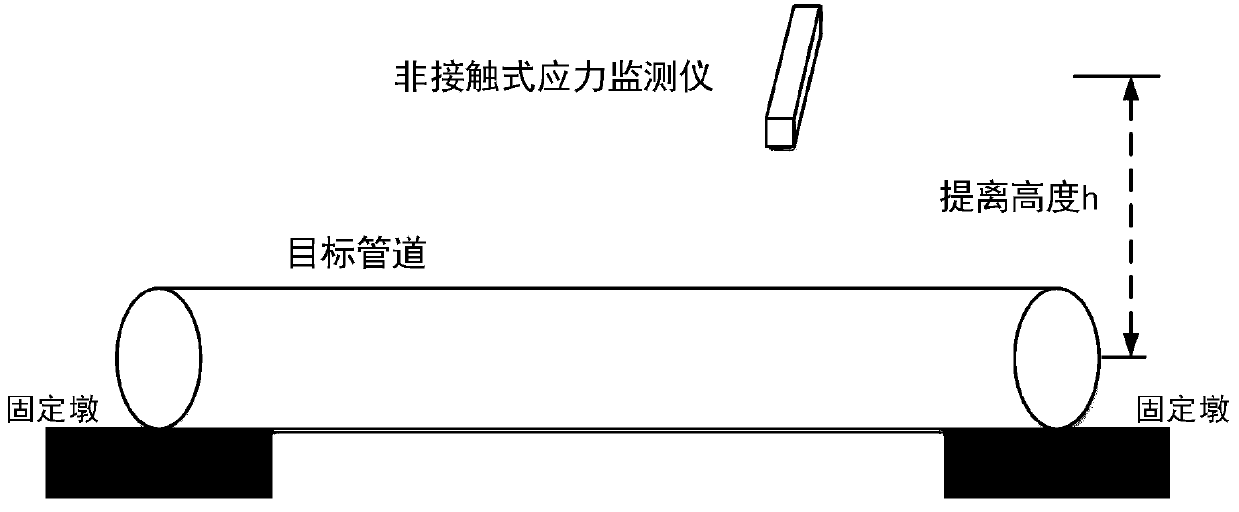

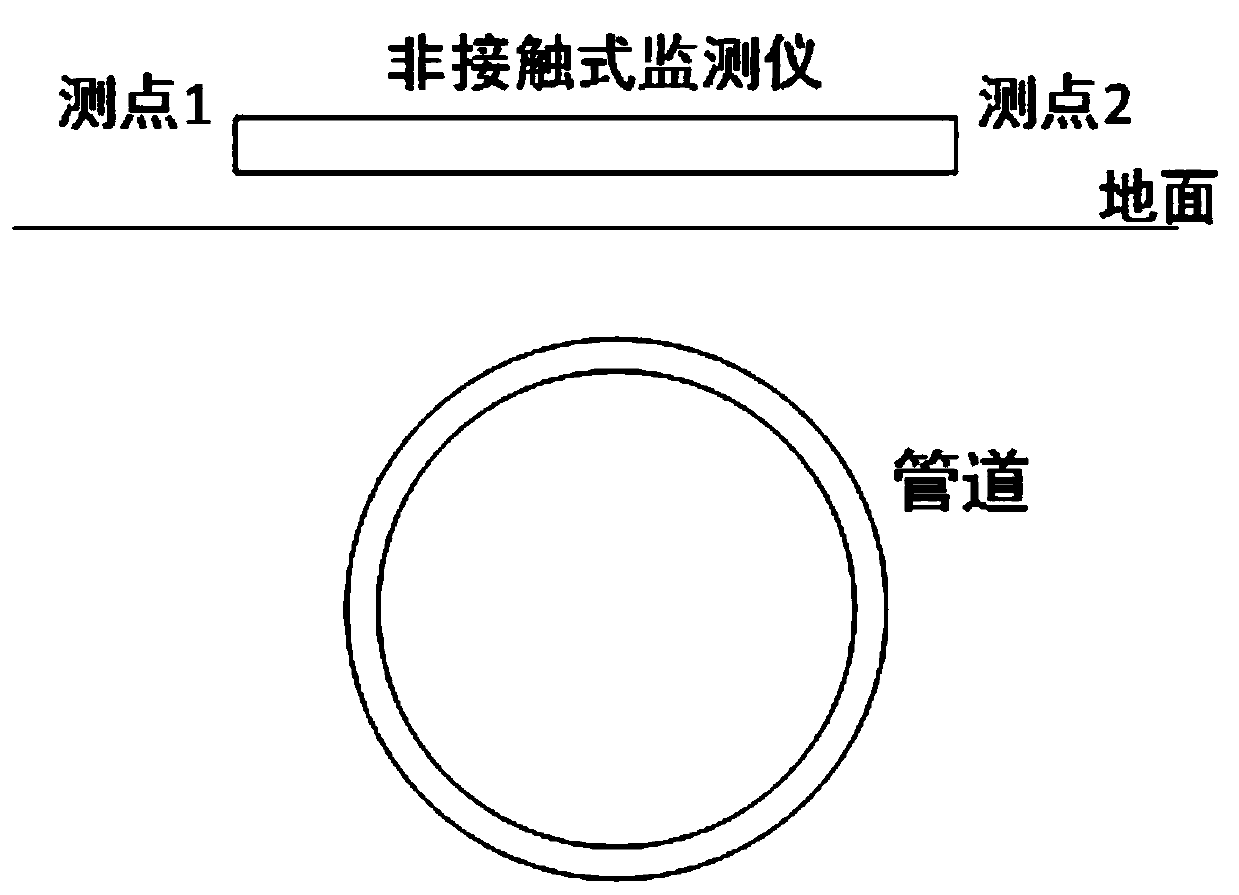

[0034] Step S10, (such as figure 2 (shown) Select a pipeline with the same material, pipe diameter and wall thickness as the buried pipeline to test the lift-off effect, and obtain multiple sets of lift-off magnetic field gradient moduli G under multiple sets of lift-off heights h 1 ;

[0035] Step S20, using matlab to fit G 1 -h relationship curve to obtain the lift-off gradient modulus G 1 The parameter a in the quantitative relationship between lift-off height h 1 , b 1 、a 2 , b 2 The numerical size of; Described quantitative relational expression is:

[0036]

[0037] In the formula: G 1 is the lift-off magnetic field gradient modulus; h is the lift-off height; a 1 , b 1 、a 2 , b 2 parameters res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com