Bottom valve of tank truck

A technology for tank trucks and bottom valves is applied in the field of bottom valves for tank trucks, which can solve the problems of opening, leaking, and complicated operation of the sealing head, and achieve the effects of preventing leakage and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

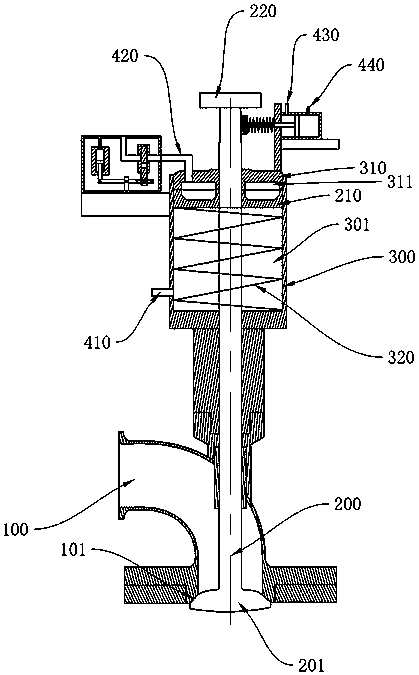

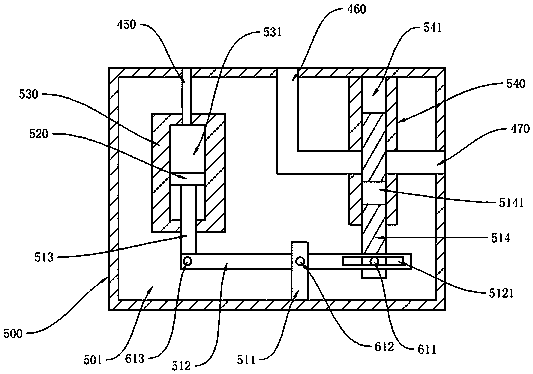

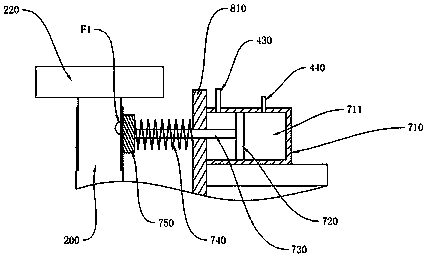

[0025] see Figure 1-Figure 4 , a bottom valve for tank trucks, including a pipeline 100, the left end of the pipeline 100 communicates with the interior of the tank truck, and the bottom end is sealed and assembled with the sealing head 201. Preferably, a sealing surface 101 is provided at the assembly position of the pipeline 100 and the sealing head 201;

[0026] The sealing head 201 is assembled and fixed with the bottom of the valve stem 200, and the top of the valve stem 200 passes through the cylinder 300 and is assembled and fixed with the top block 220;

[0027] The interior of the cylinder 300 is an installation cavity 301, and the installation cavity is provided with a sealing cover 310, a power disc 210, and a return spring 320 from top to bottom, and the power disc 210 is assembled and fixed with the valve stem 200;

[0028] The return spring 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com