Method for promoting carbonization of quicklime by taking calcium carbonate as template agent

A technology of calcium carbonate and quicklime, which is applied in the field of building materials, can solve problems affecting performance and waste, and achieve the effects of improving utilization rate, increasing carbonization degree, and increasing reaction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

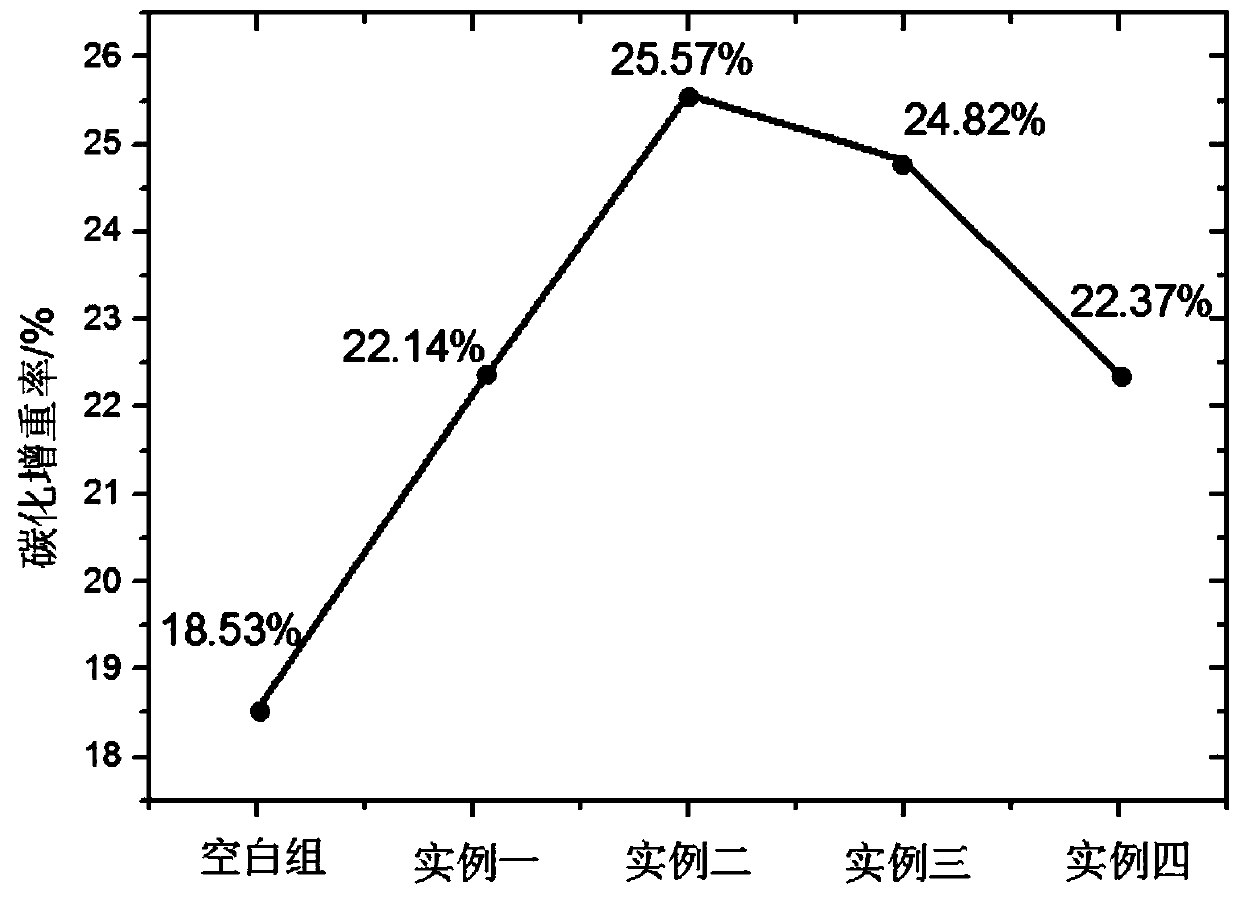

Embodiment 1

[0027] 1) Put the calcium carbonate into a ball mill according to the ball-to-material ratio of 20:1 for ball milling for 10 minutes, then grind it with a mortar, and pass through a 500-mesh sieve for subsequent use;

[0028] 2) Weigh the calcium carbonate obtained in step 1 according to 0.3% of the quicklime mass, and mix the quicklime and calcium carbonate in a beaker evenly;

[0029] 3) add water according to 50% of the total mass of quicklime and calcium carbonate, and stir evenly;

[0030] 4) Put the uniformly stirred powder together with the beaker into the reaction kettle for curing, the curing pressure is 0.05MPa, and the curing time is 2h; after curing, a product with an increased degree of carbonization than unmodified quicklime is obtained.

Embodiment 2

[0032] 1) Put the calcium carbonate into a ball mill according to the ball-to-material ratio of 20:1 for ball milling for 120 minutes, then grind it with a mortar, and pass through a 500-mesh sieve for subsequent use;

[0033] 2) Weigh the calcium carbonate obtained in step 1 according to 1.7% of the quicklime mass, and mix the quicklime and calcium carbonate in a beaker;

[0034] 3) add water according to 35% of the total mass of quicklime and calcium carbonate, and stir evenly;

[0035] 4) Put the uniformly stirred powder together with the beaker into the reaction kettle for curing, the curing pressure is 0.3MPa, and the curing time is 2h; after curing, a product with an increased degree of carbonization than unmodified quicklime is obtained.

Embodiment 3

[0037] 1) Put the calcium carbonate into a ball mill according to the ball-to-material ratio of 20:1 for ball milling for 80 minutes, then grind with a mortar, and pass through a 500-mesh sieve for subsequent use;

[0038] 2) Weigh the calcium carbonate obtained in step 1 according to 2.5% of the quicklime mass, and mix the quicklime and calcium carbonate in a beaker;

[0039] 3) add water according to 30% of the total mass of quicklime and calcium carbonate, and stir evenly;

[0040] 4) Put the uniformly stirred powder together with the beaker into the reaction kettle for curing, the curing pressure is 0.05MPa, and the curing time is 2h; after curing, a product with an increased degree of carbonization than unmodified quicklime is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com