A Design Method for the Development and Dimensions of Extrusion Mouth Plates

A technology of pressure outlet type and design method, which is applied in the field of development and size design of the pressure outlet type plate, can solve the problems of uneven opening standards of the mouth type plate, low pass rate of one-time opening plate, etc., and achieve high promotion and practical application value , Improve production efficiency, reduce the effect of training cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to understand the above-mentioned purposes and advantages of the utility model more clearly, the specific implementation of the utility model is described in detail below in conjunction with the accompanying drawings:

[0043] A method for developing dimension design of an extrusion outlet pattern, specifically comprising the following steps:

[0044] Step 1, determine the opening width of the mouth plate, and the opening width includes shoulder width and full width;

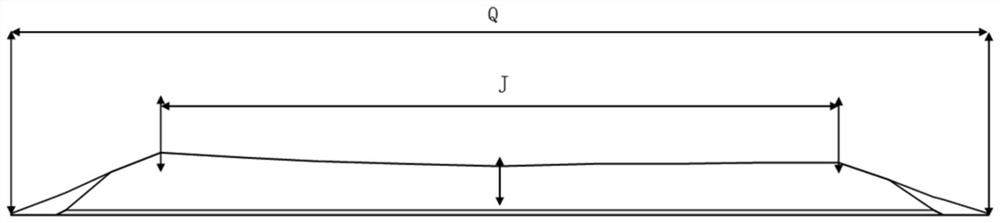

[0045] (1) Extrude the width of the extruded parts under the same specifications, the same rubber type, the same screw speed and different die widths to determine the optimal die width. The schematic diagram of the die width is as follows image 3 As shown, where the shoulder width is J, and the overall width is Q;

[0046] (2) Differentiate the type of machine, and analyze and design the details of the width and size of the mouth plate;

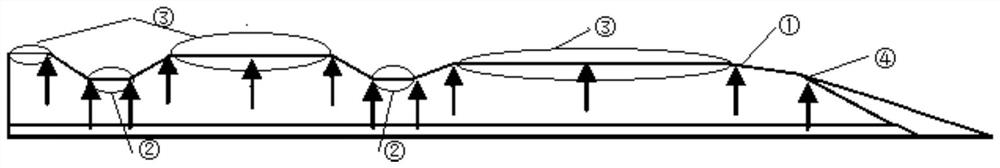

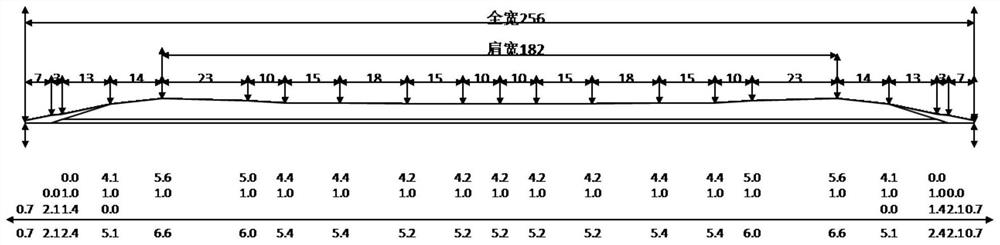

[0047] Such as Figure 4 As shown, the opening width o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com