Sludge-based magnetic nitrogen-doped biochar catalyst and preparation method thereof

A nitrogen-doped, biochar technology, used in physical/chemical process catalysts, chemical instruments and methods, water pollutants, etc., to achieve high-efficiency degradation, wide source of raw materials, and solution to purification problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Add 50mL of concentrated sludge from urban sewage treatment plants (water content 97.6%, organic matter content 50.4%, inorganic ash mainly composed of calcium, iron, aluminum, silicon, manganese and other elements, wherein the iron element content is 2%) and 0.06 g melamine and 0.06g straw (the weight ratio of dry sludge, melamine, and straw is 1:0.05:0.05), and placed in an ultrasonic cleaner to mix evenly, dried at 105°C, and ground to below 50 mesh, the mixture was placed Put it in a crucible, cover it, put it in a muffle furnace, bake it at 300°C for 6 hours, and then cool it down to room temperature naturally to get NBC-1.

[0018]Add 20mg of NBC-1 to methylene blue, methyl orange or rhodamine B wastewater containing 0.01-1mmol / L. After adsorption balance, add a certain amount of oxidant PMS to catalyze the degradation and mineralization of organic matter. The research results showed that the removal rate of the three dyes by NBC-1 was above 90%.

Embodiment 2

[0020] Add 50mL of concentrated sludge from paper mill sewage treatment plant in the crucible (moisture content 92.7%, organic matter content 40.8%, inorganic ash is mainly composed of elements such as calcium, iron, aluminum, silicon, manganese, wherein iron element content is 5%;) Mix with 1.825g urea and 1.825g sawdust (the weight ratio of dry sludge, urea, and sawdust is 1:0.5:0.5), and place in an ultrasonic cleaner to mix evenly, dry at 105°C, and grind to below 50 mesh. The mixture was placed in a crucible, covered and placed in a muffle furnace. It was calcined at 550°C for 3 hours and then cooled down to room temperature naturally to obtain NBC-2.

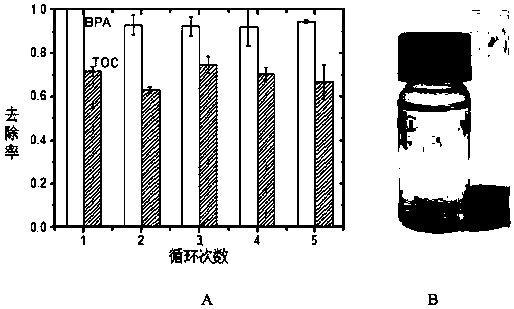

[0021] Add 2-40mg NBC-2 to 0.1mmol / L phenol or bisphenol A wastewater, after adsorption balance, add 0.05-2mmol / L oxidant PMS to catalyze degradation and mineralization of organic matter. The research results show that the removal rate of phenol and bisphenol A by NBC-2 increases with the increase of NBC-2 and PMS addition...

Embodiment 3

[0024] Add 50mL of concentrated sludge from industrial park sewage treatment plant (water content 97.1%, organic matter content 42.2%, inorganic ash is mainly composed of elements such as calcium, iron, aluminum, silicon, manganese, wherein iron element content is 7%) in the crucible 2.9g of guanidine hydrochloride and 2.9g of peanut shells (the weight ratio of dry sludge, guanidine hydrochloride, and peanut shells is 1:2:2), and placed in an ultrasonic cleaner, mixed evenly, dried at 105°C, and ground to 50 mesh Next, put the mixture in a crucible, cover it and place it in a muffle furnace, bake it at 700°C for 1 hour, and then cool it down to room temperature naturally to obtain NBC-3.

[0025] Add 20mg NBC-3 to the antibiotic wastewater containing 0.1mmol / L. After the adsorption balance, add 1mmol / L oxidant PMS to degrade and mineralize the organic matter. The research results showed that the removal rate of antibiotics by NBC-3 was above 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com