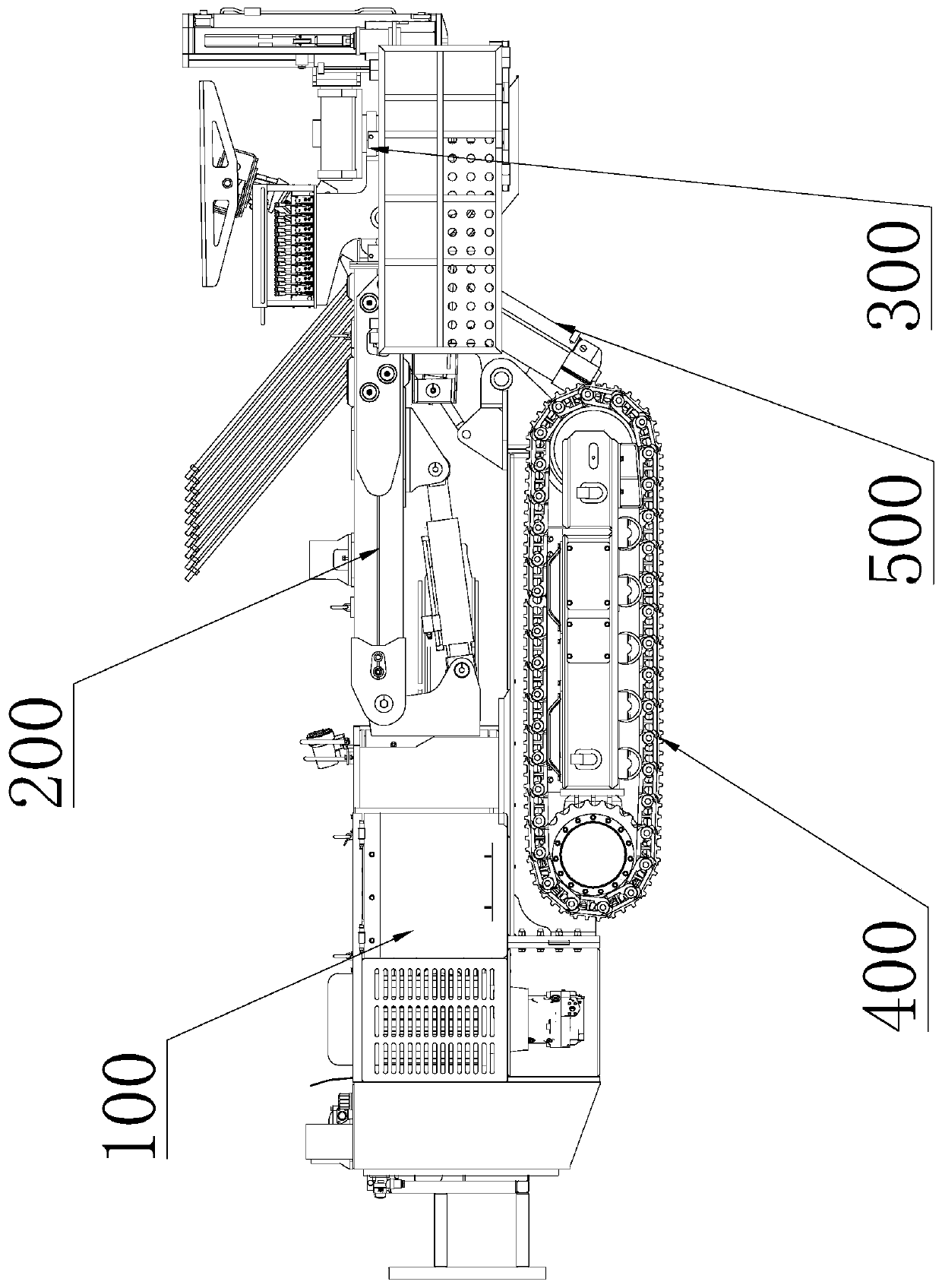

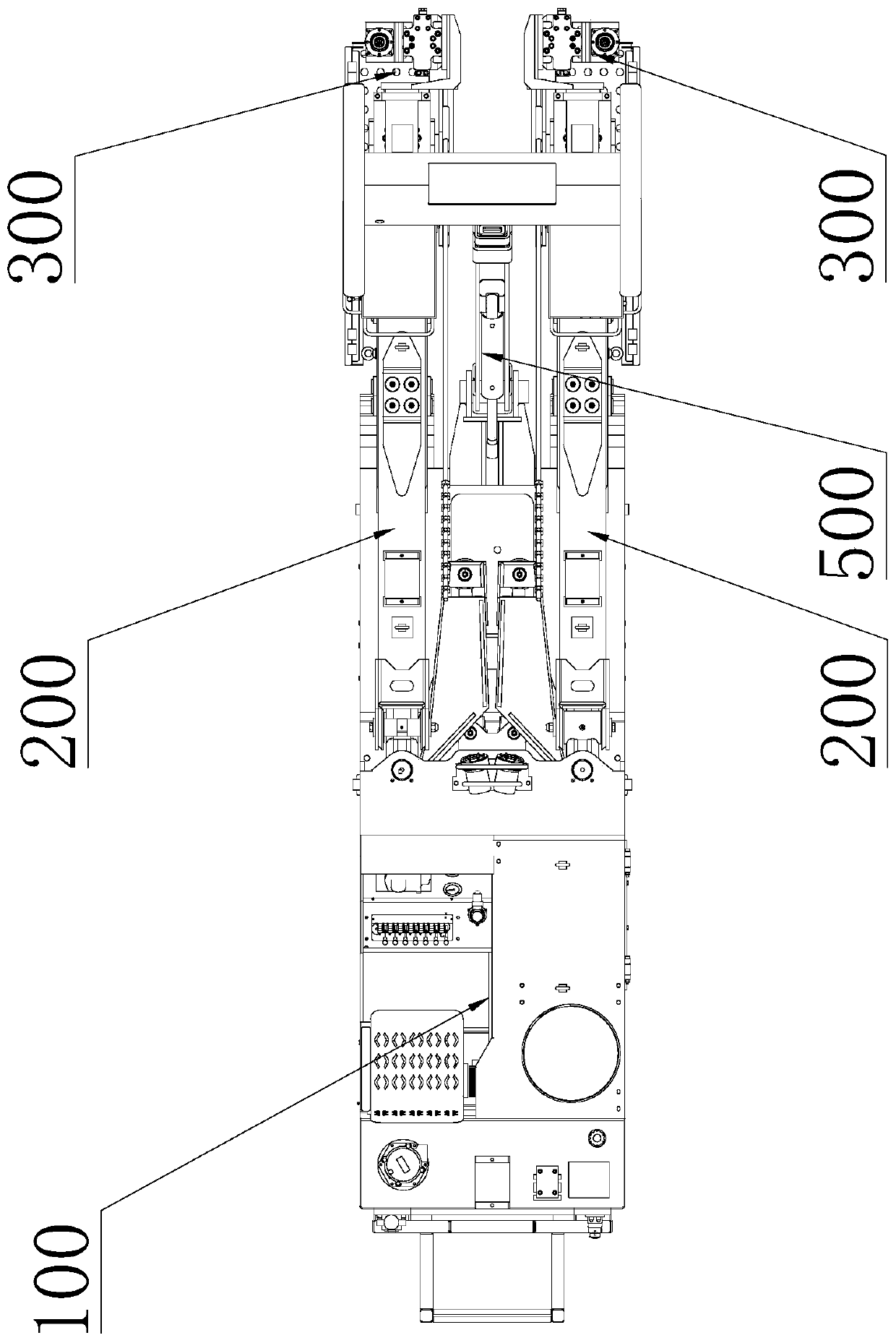

Mine anchor roddrill carriage

A bolt drilling rig and anchoring technology, which is used in the installation of bolts, drilling equipment, mining equipment, etc., can solve the complex structure of the manipulator, affecting the movable range of the manipulator, the movement accuracy of the bearing strength, the cost of the manipulator, and the later maintenance. problems such as rising costs, etc., to achieve the effects of simple structure, low manufacturing cost and reasonable setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The basic structure is the same as the basic embodiment, the difference is that the present invention provides a novel mechanical arm, that is, a working arm 200 is provided, and the working arm 200 includes at least two sub-arms 7, as Figure 1-10 The two sub-arms 7 shown are taken as an example. The sub-arm 7 close to the body 100 is called the last sub-arm 7z, and the other sub-arm is called the first sub-arm 7a. The last One sub-arm 7z is a hollow structure, part of the first sub-arm 7a is inserted into the last sub-arm 7z, and the first sub-arm 7a and the last sub-arm 7z are slidably fitted along their own length. A telescopic cylinder 12 is provided in the last sub-arm 7z, and the telescopic cylinder 12 can adopt an air cylinder or various hydraulic cylinders. The rod body of the telescopic cylinder 12 is connected with the last sub-arm 7z, and the piston rod of the telescopic cylinder 12 is connected with the The last sub-arm 7z is connected, so that the relative...

Embodiment 2

[0044] The basic structure is the same as that of Embodiment 1, the difference is: as Figure 6-9 The anchoring actuator shown includes a bearing base 1, the front end of the bearing base 1 is installed with a propulsion mechanism 2 for pushing the anchor rod, the rear end of the bearing base 1 is provided with a mounting part 1.1, and the bearing base 1 On both sides of the propulsion mechanism 2 are respectively provided with a working platform 3 and a bolt warehouse 4. The working platform is a platform for operators to stand and work, and the bolt warehouse 4 is an existing mechanism that can be used to store bolts, and the operator can place multiple bolts in the bolt warehouse 4 in advance , thereby facilitating the process of placing the anchor rods in the anchor rod bin 4 into the propulsion mechanism 2 one by one in the operation engineering to complete the anchoring process.

[0045] The propulsion mechanism 2 is used to drive the anchor rod into the area to be anch...

Embodiment 3

[0047] The basic structure is the same as that of the second embodiment, the difference is that: the upper end of the bearing seat 1 is provided with a batching bin 5 . The batching bin is used for storing other accessories and auxiliary materials except anchor rods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com