Novel flue gas thermal oil recovery equipment

A technology for thermal oil recovery and flue gas, which is applied in the fields of fluid extraction, earth-moving drilling, cleaning appliances, etc. It can solve the problems of high temperature gas pollutants, consumption of large fossil fuels, and large structure, and achieve the reduction of greenhouse effect, reasonable structure, The effect of saving flue gas generating device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is a further description of the present invention in conjunction with the accompanying drawings and embodiments.

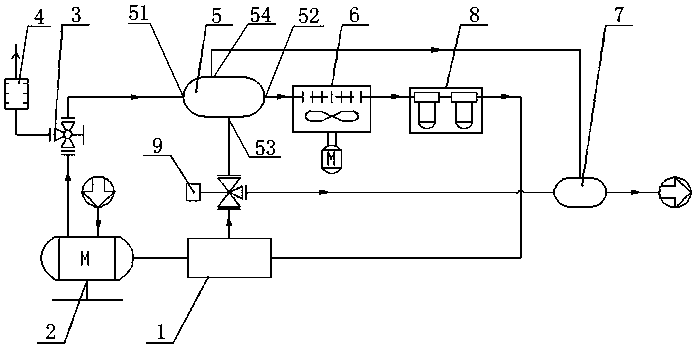

[0021] refer to figure 1 , a new type of flue gas thermal oil recovery equipment, including waste heat recovery heat exchange system, flue gas pressurization system, cooling system, purification and filtration system, gas mixing system and flow regulation control system.

[0022] The flue gas booster system is mainly composed of a flue gas booster 1, which can boost the flue gas pressure to a maximum of 50Mpa. The flue gas booster 1 should be selected to be resistant to flue gas acid gas corrosion;

[0023] The waste heat recovery heat exchange system is mainly composed of waste heat recovery heat exchanger 5. The waste heat recovery heat exchanger 5 is a tank structure with built-in heat exchange coils. The supercharged low-temperature flue gas provides a heat exchange unit, and the temperature of the supercharged flue gas after heat exchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com