Shale gas horizontal well high pressure bridge plug pumping device

A technology of horizontal wells and high-pressure pumps, which is applied in wellbore/well components, production fluid, earthwork drilling and production, etc. It can solve problems such as weak sand-carrying ability of slick water fracturing fluid, large friction loss, and inability to meet simultaneous construction. , to achieve the effect of avoiding abnormal damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

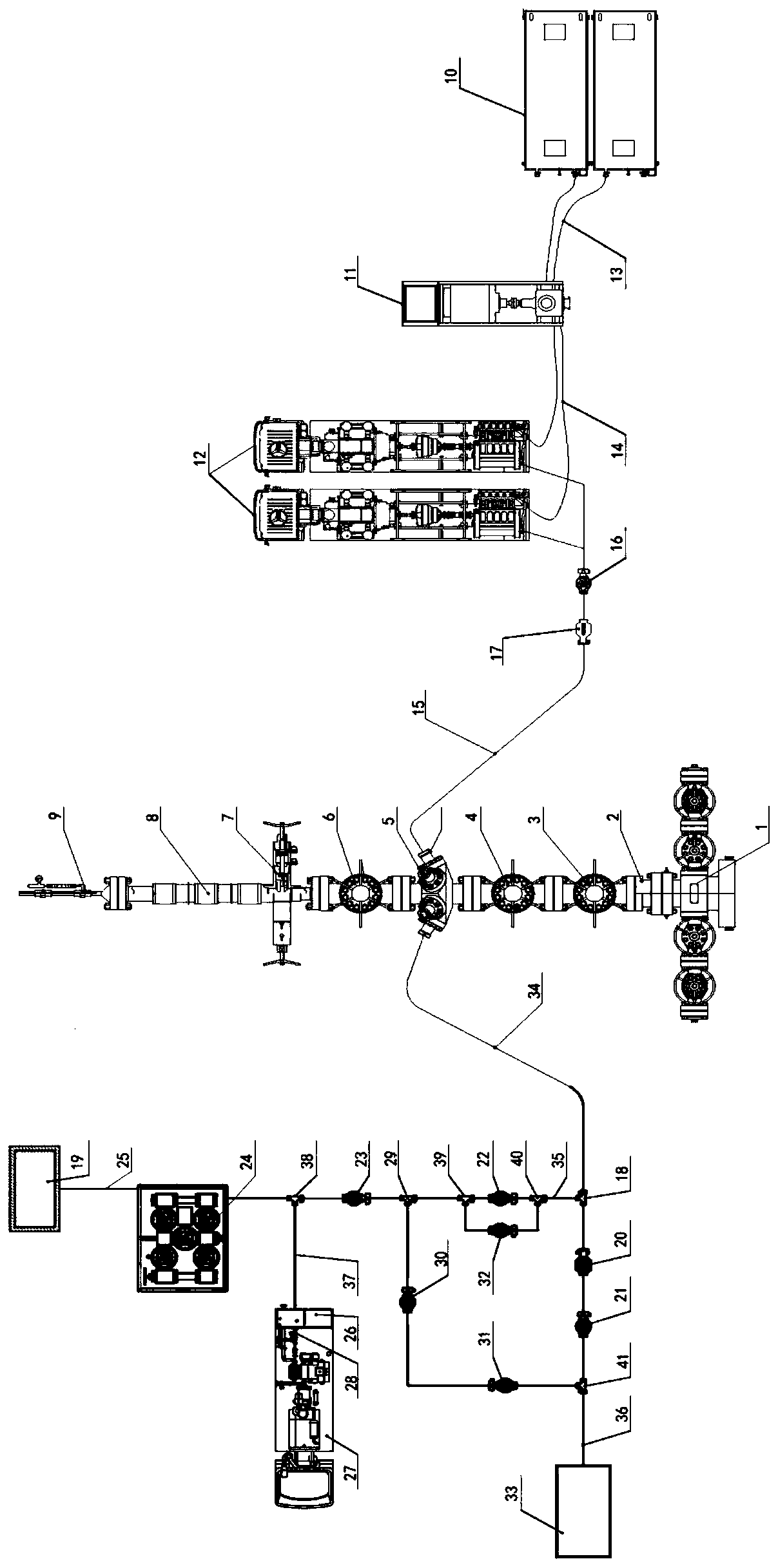

[0020] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0021] In the shale gas horizontal well high-pressure pumping bridge plug device according to the present invention, it includes a wellbore 1, a wellhead mechanism, a wellhead bridge plug packaging mechanism, a bridge plug pumping mechanism and a fracturing fluid pumping mechanism, the wellhead mechanism and The wellhead bridge plug packaging mechanism is connected to the wellbore 1, and the bridge plug pumping mechanism and the fracturing fluid pumping mechanism are both connected to the wellbore 1 by pipelines. Since the bridge plug pumping mechanism and the fracturing fluid pumping mechanism of the shale gas horizontal well high-pressure pumping bridge plug device are set separately, it can realize the independent con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com