Granular composite fertilizer pelleting adhesive and preparation method thereof

A technology of compound fertilizer and binder, which is applied to fertilization devices, fertilizer mixtures, solid/semi-solid fertilizers, etc. It can solve the problems of increasing energy consumption and achieve the effect of high granulation rate and low addition amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

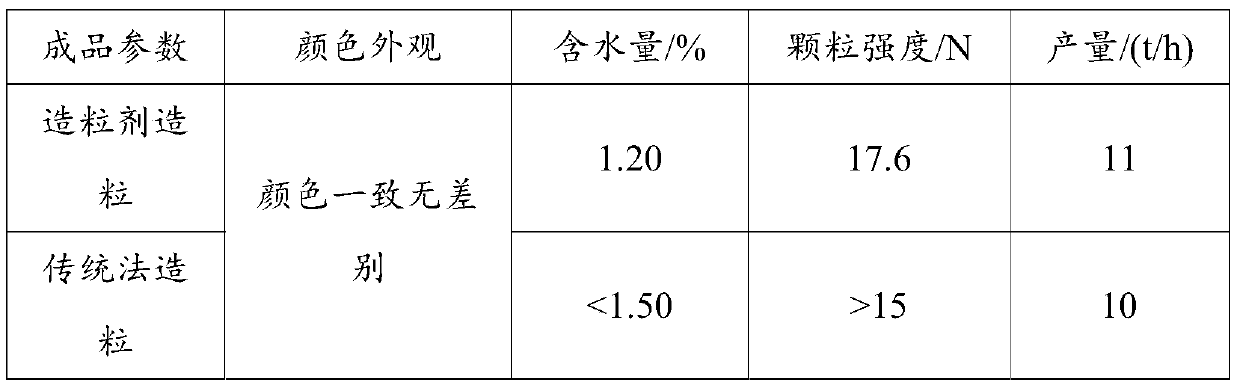

[0050] This production test was carried out in Shandong Linyi Zhongnong Sainty Ecological Fertilizer Co., Ltd. The production equipment is the production process of drum agglomeration method. The traditional granulation method uses urea-formaldehyde (liquid), monoammonium phosphate slurry and steam for granulation. The equipment and process index parameters are as follows:

[0051] Granulator length: 7.4m Granulator diameter: 2.2m

[0052] Drying kiln length: 28m Drying kiln diameter: 2.4m

[0053] Cooling cylinder length: 28m Cooling cylinder diameter: 2.2m

[0054] One mixer, one ton each time, intermittent feeding

[0055] Drying kiln head temperature: 180°C Drying kiln tail temperature: 55°C

[0056] Packing temperature after cooling: 40°C

[0057] Material temperature at the exit of the granulator: 55-60°C

[0058] The production formula is: 28-6-6 (potassium sulfate type)

[0059] Addition amount of granulation steam: 40kg / T, addition amount of urea-formaldehyde: 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com