Environment-friendly multi-stage building rubbish crushing treatment device

A construction waste and processing device technology, applied in grain processing, dust removal, cleaning methods and appliances, etc., can solve problems such as poor crushing effect, single crushing method, air pollution, etc., and achieve the effect of improving the crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

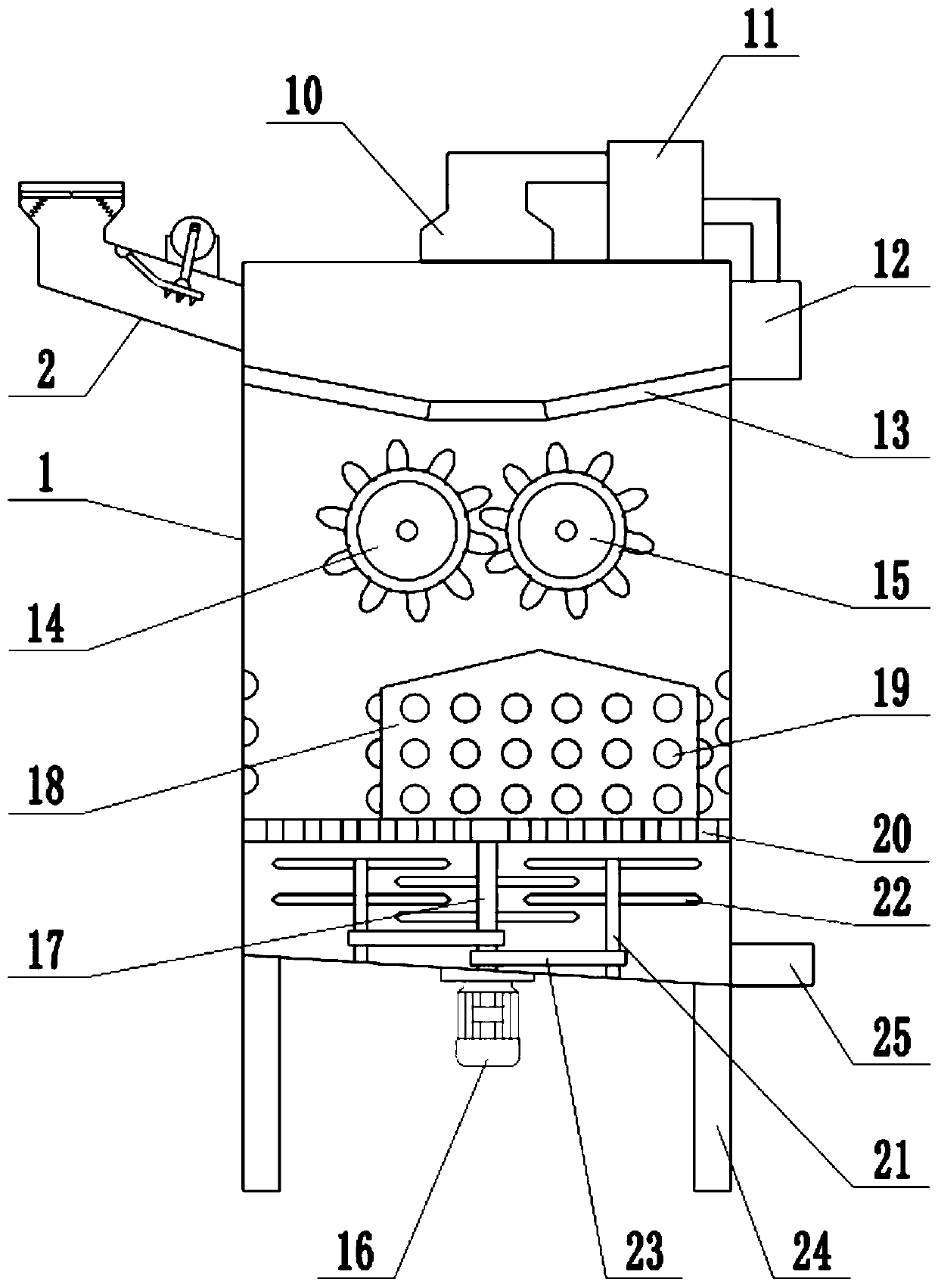

[0021] see Figure 1-3 , in an embodiment of the present invention, an environment-friendly multi-stage construction waste crushing and processing device includes a housing 1, an active crushing roller 14 and a driven crushing roller 15, a feeding port 2 is installed above the side wall of the housing 1, and the feeding port 2 The opening is provided with a baffle 3, and there are two baffles 3, symmetrically arranged left and right, the baffle 3 is hinged with the inner wall of the feeding port 2, the lower surface of the baffle 3 is fixedly connected with a spring 4, and the lower end of the spring 4 is connected to the feeding port 2. The inner wall is fixedly connected, and under the action of the spring 4, the two baffles 3 are closed, and the construction waste to be crushed is put into the feeding port 2. Under the action of gravity, the baffle 3 is opened, and the construction waste passes through the feeding port 2. Enter the casing 1, under the action of the spring 4...

Embodiment 2

[0023] On the basis of Embodiment 1, the left and right sides of the driving shaft 17 are provided with driven shafts 21, the lower end of the driven shaft 21 is rotationally connected with the bottom of the housing 1, and the driving shaft 17 is connected with the driven shaft 21 through a transmission belt 23, The driving shaft 17 and the driven shaft 21 are interlaced with crushing blades 22. When the driving shaft 17 rotates, the driven shaft 21 is driven to rotate through the transmission belt 23, and the construction waste is further crushed by the crushing blades 22. There is a discharge port 25 through which the crushed construction waste is discharged, and the bottom of the shell 1 is provided with a leg 24 .

Embodiment 1、 Embodiment 2

[0024] In combination with Embodiment 1 and Embodiment 2, the working principle of the present invention is: put the construction waste to be crushed into the feeding port 2, under the action of gravity, the baffle plate 3 is opened, and the construction waste enters the shell 1 through the feeding port 2, and Under the action of the spring 4, the baffle plate 3 returns to the horizontal position to prevent the construction waste dust from escaping, start the air extractor 11 and the air filter 12, use the air extractor 11 to extract the dusty gas in the shell 1, and use the air to filter The device 12 filters the dusty gas to avoid pollution caused by the direct discharge of the dusty gas. The construction waste that has been preliminarily crushed falls on the guide plate 13, passes through the through hole in the middle of the guide plate 13, and falls to the active crushing roller 14. Between the movable crushing rollers 15, a drive motor is installed on the outer wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com