Direct-drive type double-stator oblique-pole double-freedom-degree permanent magnet generator for ocean energy power generation

A technology of permanent magnet generator and double stators, which is applied in ocean energy power generation, engine components, machines/engines, etc. It can solve problems such as limiting energy utilization efficiency, and achieve the effects of improving power generation quality, reducing positioning force, and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

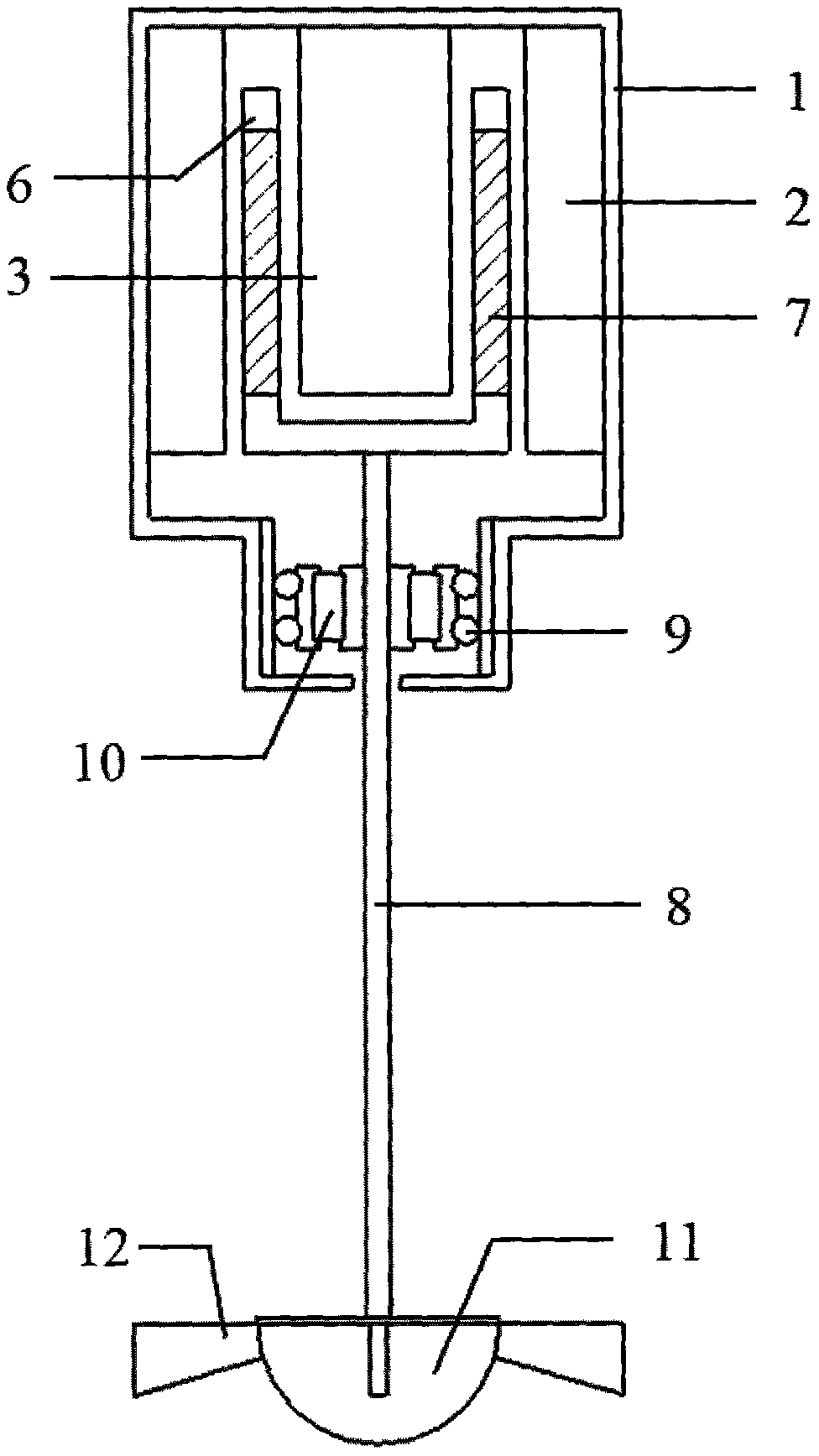

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

[0019] Such as figure 1 As shown, the waterproof casing (1) wraps the cylindrical double-stator permanent magnet generator, and the waterproof casing (1) is fixed with the outside world to keep it still; the outer stator core (2) and the inner stator core (3) of the motor are fixed to the waterproof casing (1); the permanent magnet (7) is embedded in the mover iron core (6), and the mover iron core (6) is connected with the upper end of the circular shaft (8), and the three can move synchronously; the linear motion bearing (9) is embedded The rotary bearing (10), the rotary bearing is installed on the outside of the circular shaft (8), and the linear motion bearing is installed on the inside of the waterproof casing (1); since the circular shaft (8) and the waterproof casing (10) pass through the linear motion bearing (9) and The rotary bearing (10) is connected, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com